Making Custom Molds for Storing Objects

Thoughts on two ways to make form-fitting pockets: moldable materials, or CAD/CNC imaging. March 28, 2015

Question

I am looking for some material that is used to make custom forms. I think it is like polyurethane foam or something. You can press something into it and it will harden to the shape of the object.

Forum Responses

(Cabinetmaking Forum)

From Contributor W:

Try Smooth-On.

From the original questioner:

What I am looking to do is to create a custom form in a drawer to put handguns in for a client for his gun cabinet. We would lay the guns in the material to allow it to form around it and then use flocking material to finish it off making a custom fit around each of the handguns. I am going to contact this company first of the week and see if it will work for this application.

From Contributor W:

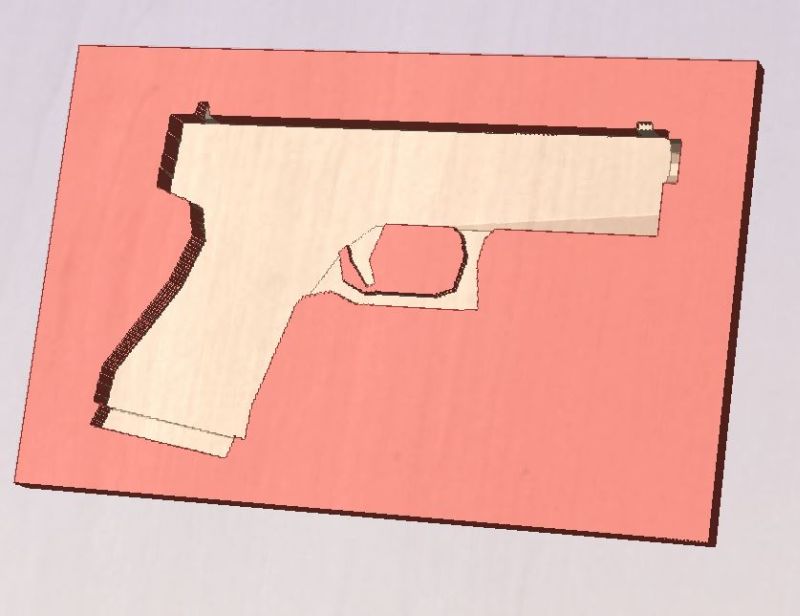

Here for example I Googled 3D pistol files and found an .obj (3D file) of a Glock. I imported it and machined it on screen. Sketchup is loaded with files.

Click here for higher quality, full size image

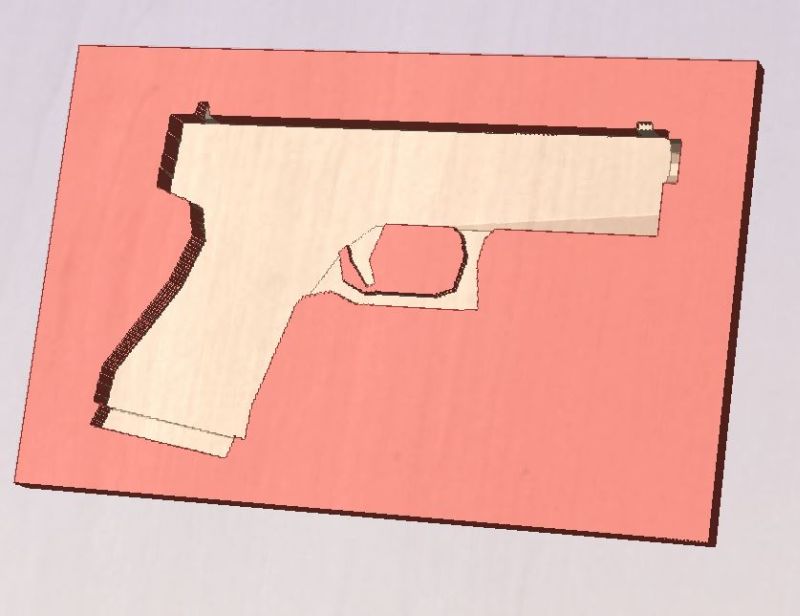

From Contributor W:

Ok so I am showing off the Aspire software. This is a sig from the same site, I don't hove on so not sure of final size. It took me all of three minutes and I am at the machine.

Click here for higher quality, full size image

From the original questioner:

Why couldn't you just take the actual gun, put a protective film between it and the material and just press it into the soft solution to make the perfect shape for the gun, remove it and let it harden?

From Contributor W:

You can. I made molds using the smooth on materials for years and I just moved on to CNC from there. Once I have the file I have it forever and no longer have a large wall of molds.

From Contributor O:

FYI - this is called "French Fitting" when a case or container holds the item in such a way that it cannot shift about, but still allows for easy removal and replacement. It is considered best to provide finger relief in a few spots and only go about half the depth/thickness of the item.

From the original questioner:

What is the material used in this process? I am going to contact the Smooth-On people soon.

From contributor C:

Kaizen foam is used for this process. Taking a silicone mold off the firearm will make an exact fit. Then adding flocking will make it really snug. Better to have a little clearance.