I disagree that you can’t predict wood expansion, you most certainly can “predict” shrinkage/expansion of wood. How good your prediction is depends on the amount of information one has but that’s a different discussion.

You are probably correct that I am over thinking this but I am not really loosing sleep over it, just looking for feedback from others who have more experience with this than I do, typically I do panels like these in laid up in veneer so I have never really thought about it.

I also realized last night as you pointed out that because in the bath it may be more stable and won’t see that much expansion/shrinkage anyways.

I am mostly concerned with the reveal staying consistent I am absolutely not concerned about the construction method.

So maybe I listed too much info and the question should have been something like:

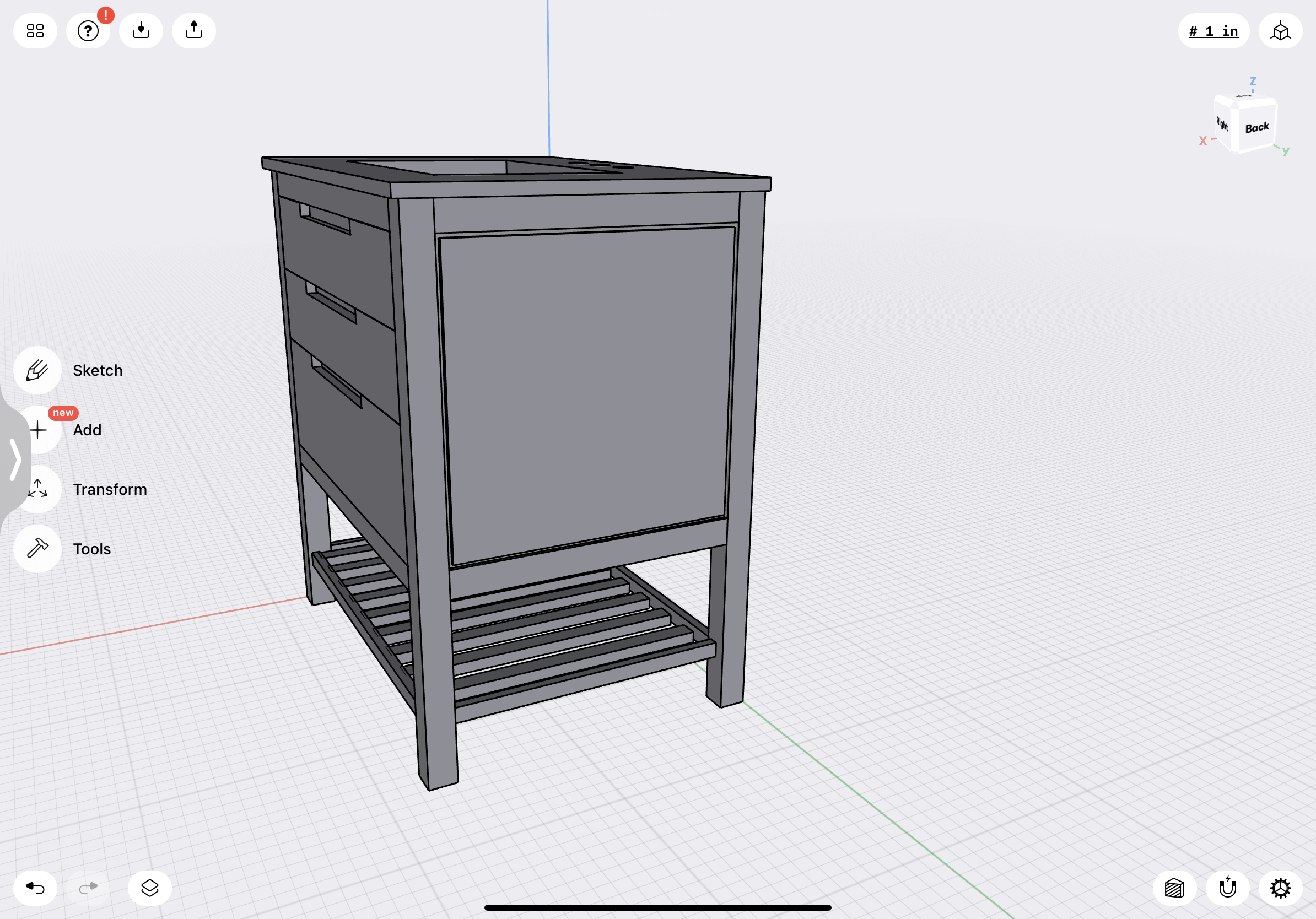

- I have a frame and panel, the panel has a 3/16” reveal on all 4 sides of the panel. I want the reveals to stay consistent through seasonal movement if any occurs. If i pin the panel in the center will the panel expand/contract evenly so that the reveal remain the same?

Why in the world would anyone share that info with the customer? I would simply say, sorry it can’t be done, plus my customers already know I am smart :)