I use full size sliding saw, meaning it can cut full 4' x 8' sheet in either direction. I would suggest you get the full-size slider if you can. Sliding saw is better than cabinet saw if you need precision, squareness and scoring blade functionality, plus it's much less physically demanding for the operator. Cabinet saw takes less space and could be faster if you don't need any of the above-mentioned benefits of sliding saw.

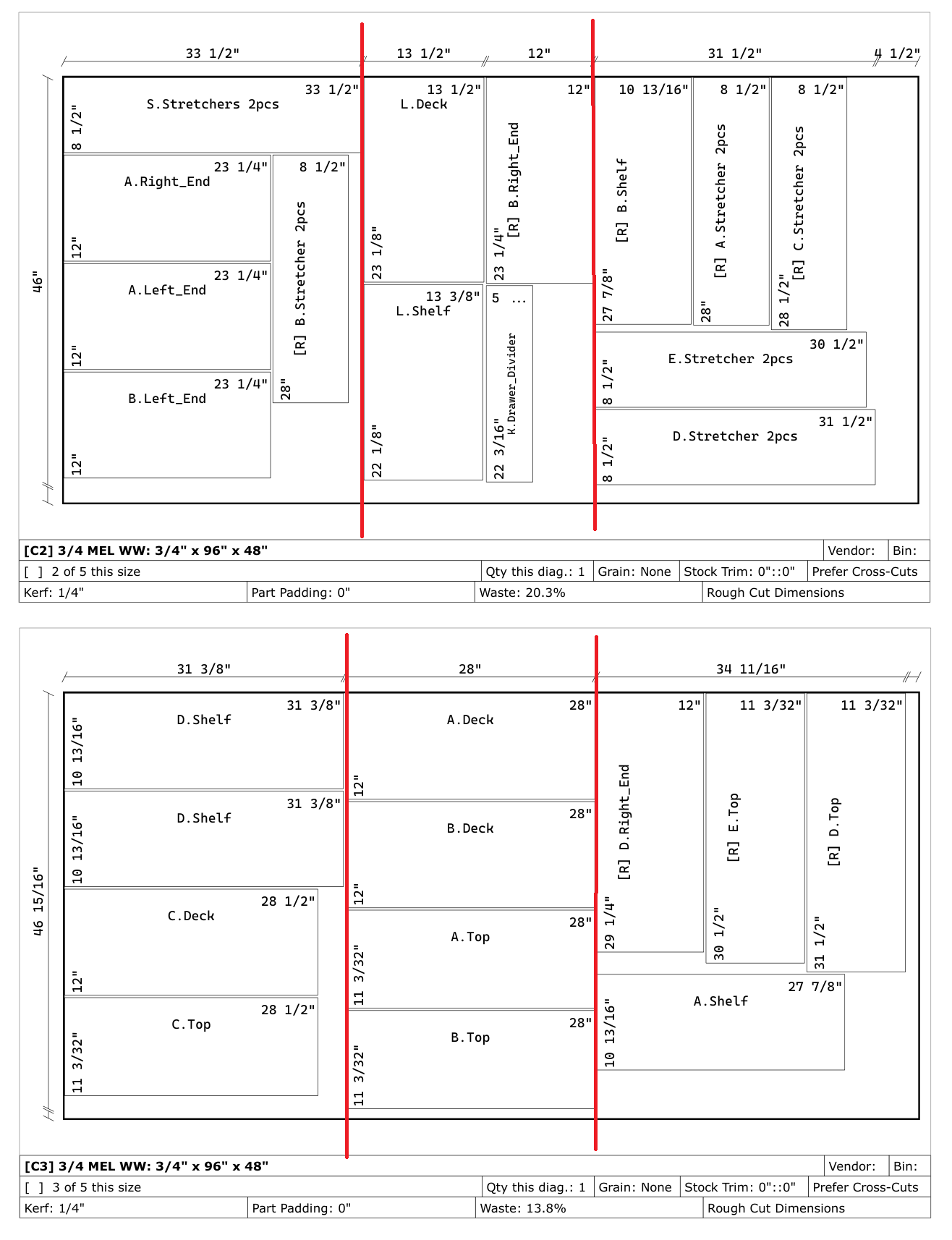

However, there is a way to be productive even with a smaller one like that Grizzly. Have a look at the drawings I attached. I've set up my sheet cutting optimizer software to align cabinet parts in such a way that cross-cuts are the ones I start with. For the cabinet sizes I cut 99.9% of time all cabinet parts are of such size that sheets usually get divided into 3 crosscut parts (see the red lines on the drawings). Then I just deal with those smaller pieces.

Even if there was some theoretically more optimized way, I would still have to do it this way because of famous "banana cuts" that I have on every melamine and most plywood sheets I cut. Basically, these 4 sides, resulting from first 2 crosscuts have to be straightened out anyway, so the fact that you can square whole sheet of material on a big sliding saw doesn't do much for me, since I have to deal with banana cuts on smaller portions later anyway. Plus, many times scoring blade doesn't work well on a whole sheet of material, since it's not easy to keep whole sheet of material completely pressed to the slider bed anyway. It's even harder with plywood than melamine.

So, if you arrange your cabinet parts like I do, you may use your existing panel saw to divide whole sheets into smaller parts (or even have other worker to do that for your), and then just use sliding saw from then on. You may even be faster that way than doing everything on a bigger slider (smaller saws are generally faster to work with than big ones). That has been an idea I've been thinking about since I got my big slider, I just don't have enough space in the shop to bring back my old panel saw from storage without obstructing other operations in the shop.