Great Question. Your question is legitimate and fair...."extremely legitimate" indeed. (Not sure if there is a phrase "extremely legitimate" or not, but you know what I mean.) Is this the right place to post it? Yes, but it is so important, it should be posted on five or six other boards too

#1. Wood shrinks and swells across the grain when the moisture content (MC) changes...swelling if the MC goes up and shrinking if the MC goes down. Wood seldom shrinks lengthwise. (The limited lengthwise shrinkage is why plywood, with the lengthwise direction being at 90 degrees in each adjacent sheet of veneer, is overall so much more stable than a solid piece of wood.)

There are two directions for across the grain- -TANGENTIAL (meaning parallel to the annual growth rings; the width of a flatsawn piece) and RADIAL (meaning perpendicular to the growth rings or the width of a quartersawn piece). The values for tangential movement would be the maximum movement; the values for radial movement would be the minimum. In practice, a perfectly flatsawn or perfectly quartersawn piece is not common, so we will likely have a bit less than the maximum for most flatsawn pieces and a bit more for most quartersawn or rift sawn pieces.

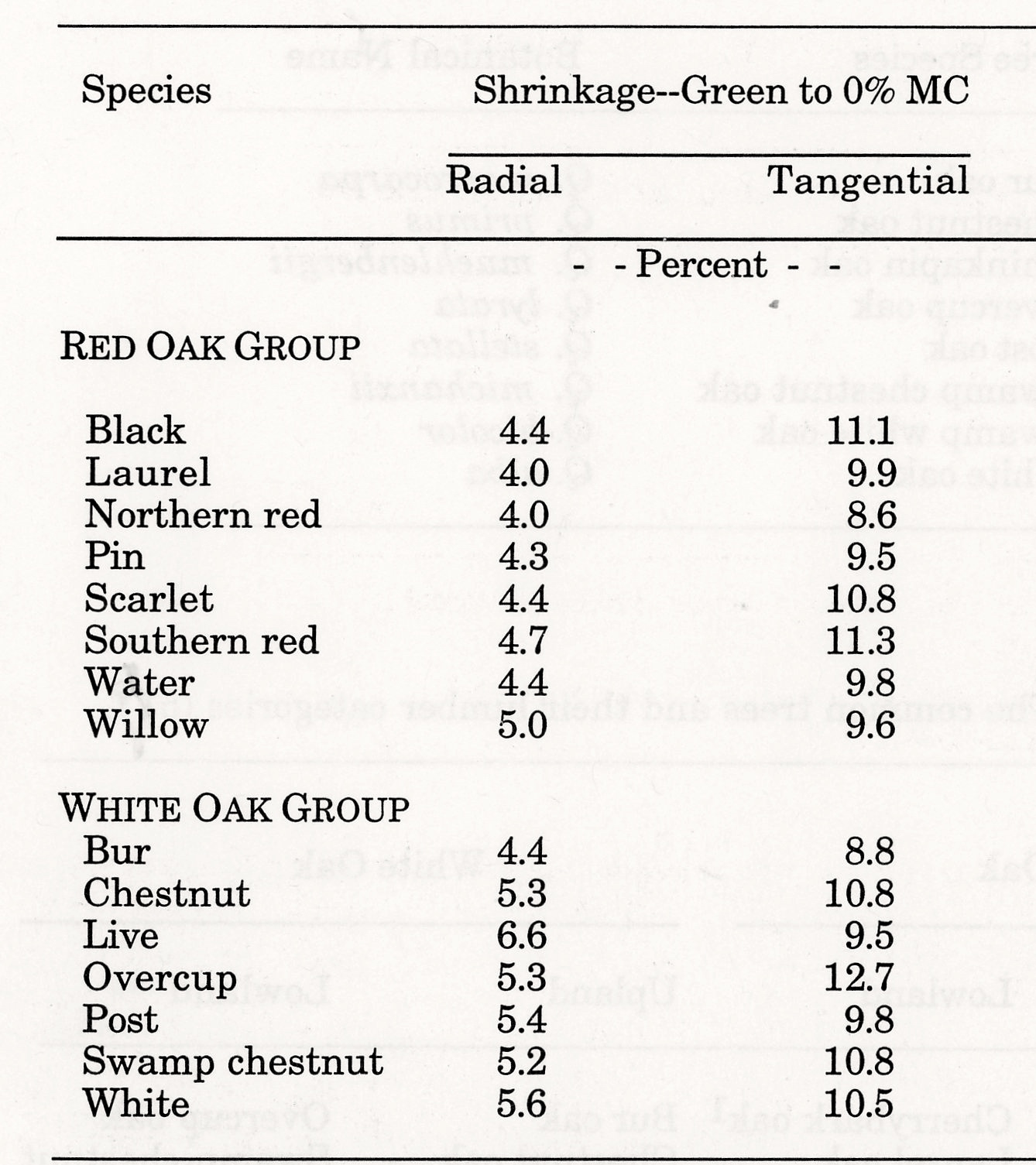

When dealing with oak, the highest shrinking commonly used species in North America, there are twenty species of red oak and twenty species of white oak that will show up in the commercial market. Each species within the grouping of red oak or white oak does move different amounts, as shown in the figure attached below.

#2. When dealing with shrinkage, green means 28% MC and 0% means 0% MC. Shrinkage from 28% to 0% (or swelling in the reverse) is a straight line with MC, so you can divide the total number by 28 to get the movement for each 1% MC change. Example, northern red oak is 4.0% radially and 8.6% tangentially. So that is (4.0 / 28 =) 0.143% size change radially for a 1% MC change, and (8.6 / 28 =) 0.307% tangentially for a 1% MC change. (Actually, the numbers are for thin pieces of wood; the thicker the wood is, the movement will be somewhat less, but not a whole lot less.

The values for every commercial species can be found in the WOOD HANDBOOK, Table 13-5 at www.fpl.fs.fed.us/documnts/fplgtr/fplgtr190/chapter_13.pdf

Two more points to go, so hang in there.

#3. The moisture content of wood changes about 1% for every 5% RH change... 0% RH = 0% MC = 0% EMC 30% RH = 6% MC = 6% EMC 50% RH = 9% MC = 9% EMC 65% RH = 12% MC = 12% EMC 80% RH = 16% MC = 16% EMC

Note that EMC (equilibrium moisture content) refers to the moisture in the air. It is the connection between humidity in the air and the MC in the wood.)

So, as a rough approximation, you could use the 0.143% and 0.307% size change for 1% MC change numbers above as the predicted size change for a 5% RH change as well.

Of course, the change is not instantaneous...the surface and ends change quickly (unless coated with a vapor resistant coating); the core may take days, weeks or months to change. (In fact, the core MC is often the MC that the lumber left the kiln at, as it takes quite a while for the core MC to change.) This slow change or movement of the core is also why thicker pieces of wood have less movement than thin pieces.

#4. Here is a minor point, but do read it please. If wood has been shrinking and the RH is lowered by 5% RH (or 1% EMC), then the wood will continue to dry by 1% MC and continue to shrink, as predicted. However, if a piece has been shrinking, but now is exposed to a humidity increase, there will actually be a lag in the response to the RH and a lag in the change from shrinking to swelling. (Technically, this is called the hysteresis effect.) This effect is why, if we have lumber that has been drying and then this lumber is a bit too wet, but we use it anyway and then the wood is put into a dry environment so that the wood dries more, the size change can be fairly significant, resulting in gluing issues like open joints, size changes, warp, etc. On the other hand, if we have dry wood and then it goes into a summertime humid environment, the swelling change will not be as big as we calculated. Knowing this fact is why we often specify an incoming moisture of 7.0% MC, as we know the wood might dry to 6.0% MC in use during the wintertime or increase to 9.0% MC use in the humid summertime, but the 9.0% EMC will actually behave more like 8.0% EMC. Then the next winter when the wood dries again, it will be 6% EMC, but due to hysteresis, it will seem like 7.0% EMC. Again, that is why we almost always see moisture problems the first year the wood is put into use because the wood is often not quite dry enough, etc. So, maybe hysteresis is not a minor point after all.

If you want even a bit more practical stuff, consider two items: A. First. Wrapping in plastic will prevent any moisture change, even if the someone stores the product you make poorly (bad humidity). A big roll of Saran type wrap from the big box stores is not expensive and can really pay off.

B. Second. Do not humidify your shop above the humidity that your customer will have. If I humidify my shop to much, I am pushing the undesired shrinkage to the customer. But, I would rather have a defect show up in my shop (where I can repair them more easily) than in the customer's home or office. Of course, if I get the correct MC in my lumber initially, then I will not have to worry. Of course, some kiln drying operations do not dry all the pieces dry enough, as it is too expensive for them (shortsighted)- -it is actually not too expensive from your point of view.