Dylan:

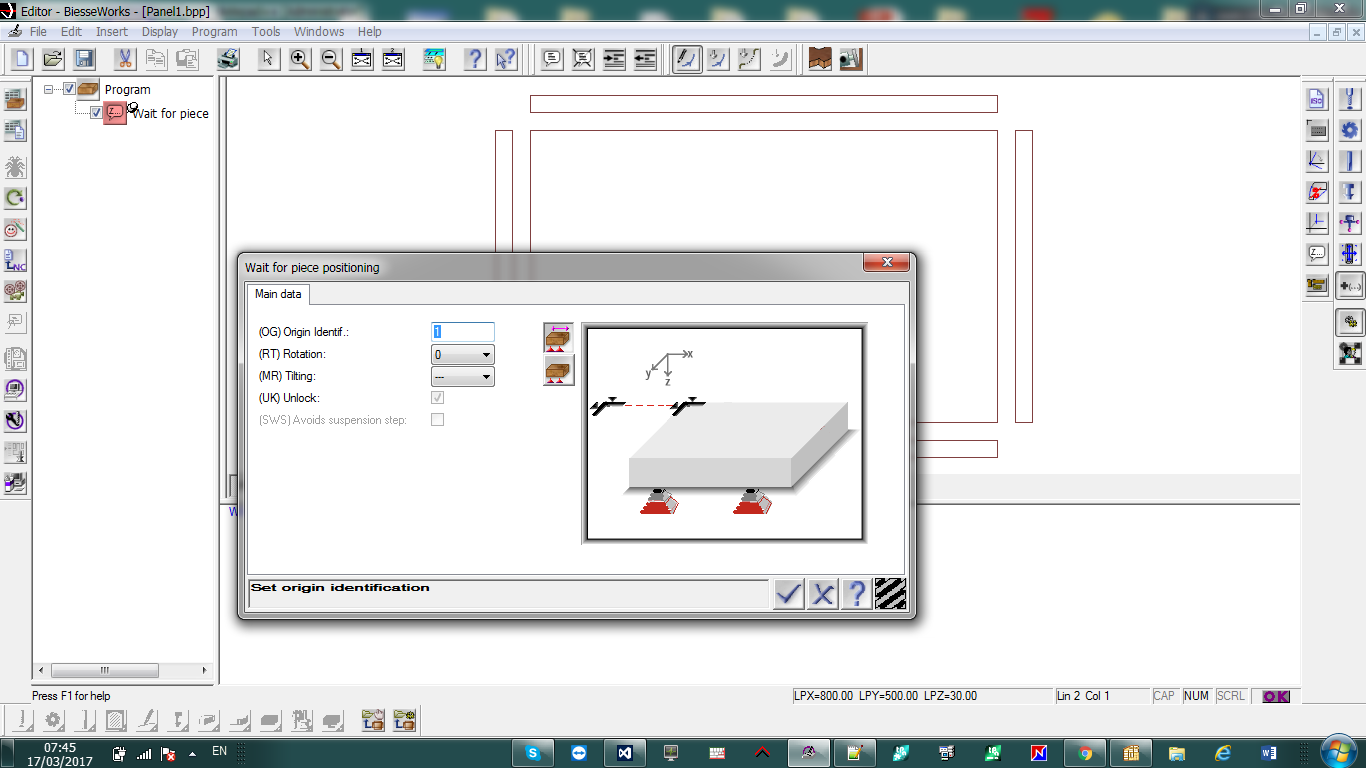

Remember, Cabinet Pro CNC writes the code directly to Biesseworks. Does your response mean that we simply add the line,

@ WAIT, "", "", 39530916, "", 0 : 0, 1, 0, 0, 1, 0

outside of any given block of code? In other words, that line as written will cause the machine to pause if inserted into the code?

For example, is the insertion shown just before the last BLOCK below correct?

BEGIN ID CID3

"C:\Cabinet Pro\CNC\CNC_TEST.CID"

REL= 3.0

AXIS=x+,y-,z-

END ID

BEGIN MAINDATA

LX=2463.8000

LY=1244.6000

LZ=16.4846

OX=0.00

OY=0.00

OZ=0.00

BEGIN TECH

CAT=0

END TECH

END MAINDATA

BEGIN BLOCK

NAME=WRK

SIDE=0

BEGIN PLINE

BEGIN TECH

CAT=0

TYP='0'

TOOLNAME=1/2" DADO BIT

WORKSPEED=0.0000

ROTSPEED=0.0000

DESSPEED=0.0000

TOOLCORTYP=R,0,R,

0

ANG=90.0000,0.0000

END TECH

LINE,XS=166.9796,YS=0.0000,ZS=9.525,XE=166.9796,YE=480.2505,ZE=9.525

END PLINE

END BLOCK

BEGIN BLOCK

NAME=WRK

SIDE=0

BEGIN PLINE

BEGIN TECH

CAT=0

TYP='0'

TOOLNAME=1/2" DADO BIT

WORKSPEED=0.0000

ROTSPEED=0.0000

DESSPEED=0.0000

TOOLCORTYP=R,0,R,

0

ANG=90.0000,0.0000

END TECH

LINE,XS=166.9796,YS=480.2505,ZS=9.525,XE=161.9250,YE=480.2505,ZE=9.525

END PLINE

END BLOCK

BEGIN BLOCK

NAME=WRK

SIDE=0

BEGIN PLINE

BEGIN TECH

CAT=0

TYP='0'

TOOLNAME=1/2" DADO BIT

WORKSPEED=0.0000

ROTSPEED=0.0000

DESSPEED=0.0000

TOOLCORTYP=R,0,R,

0

ANG=90.0000,0.0000

END TECH

LINE,XS=161.9250,YS=480.2505,ZS=9.525,XE=161.9250,YE=0.0000,ZE=9.525

END PLINE

END BLOCK

@ WAIT, "", "", 39530916, "", 0 : 0, 1, 0, 0, 1, 0

BEGIN BLOCK

NAME=WRK

SIDE=0

BEGIN PLINE

BEGIN TECH

CAT=0

TYP='0'

TOOLNAME=1/2 INCH COMPRESSION

WORKSPEED=0.0000

ROTSPEED=0.0000

DESSPEED=0.0000

TOOLCORTY

P=R,0,R,0

ANG=90.0000,0.0000

END TECH

LINE,XS=771.5250,YS=517.5250,ZS=16.6624,XE=771.5250,YE=-3.1750,ZE=16.6624

LINE,XS=771.5250,YS=-3.1750,ZS=16.6624,XE=771.5250,YE=-3.1750,ZE=16.6624

LI

NE,XS=771.5250,YS=-3.1750,ZS=16.6624,XE=-3.1750,YE=-3.1750,ZE=16.6624

LINE,XS=

-3.1750,YS=-3.1750,ZS=16.6624,XE=-3.1750,YE=-3.1750,ZE=16.6624

LINE,XS=-3.1750

,YS=-3.1750,ZS=16.6624,XE=-3.1750,YE=517.5250,ZE=16.6624

LINE,XS=-3.1750,YS=51

7.5250,ZS=16.6624,XE=-3.1750,YE=517.5250,ZE=16.6624

LINE,XS=-3.1750,YS=517.525

0,ZS=16.6624,XE=771.5250,YE=517.5250,ZE=16.6624

END PLINE

END BLOCK

(sorry for the lack of indentation. Copy & Paste did not include the indents.)