Blanks with lines drawn

3/8 x 3" dowel and hole

ID cut out and set up

Glued up using a band clamp and TiteBond II

Box of spokes from my turner

Close up of rough spoke

Setup for sanding the rims ID using a RoboSander drum sander with a bottom bearing

Close up

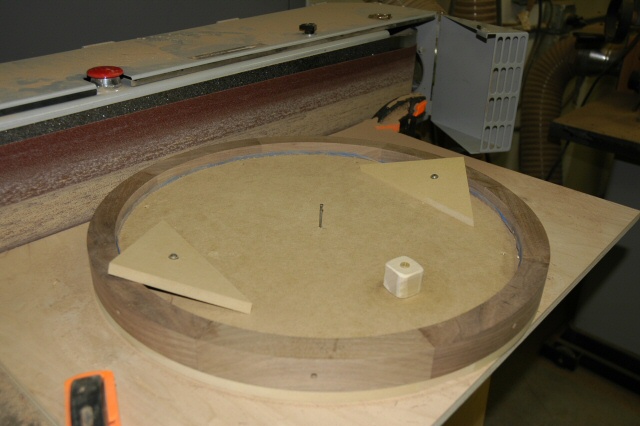

Jig for sanding the OD of the rim using my edge sander

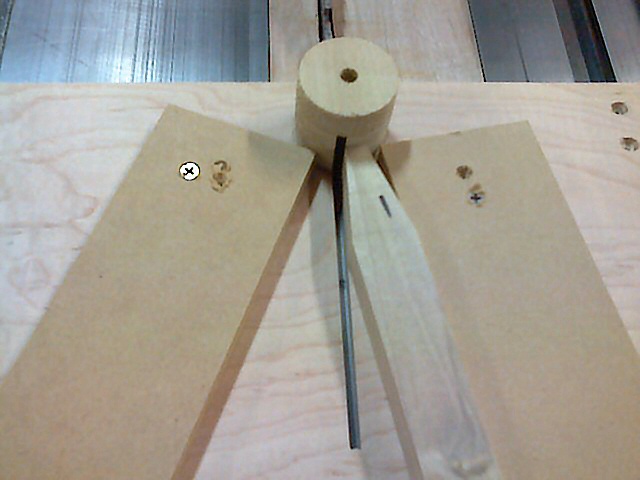

Setup to cut right hub side of spoke

Setup to cut left hub side of spoke

1st try has a 1/4" gap

After 6 adjustments

The real deal. 1st run to tight

Center close up

Used blue tape on the jig to get it perfect

Got all of them in

Close up

It''s a wheel !

The brass hub that was provided to me

How I lined up the spoke holes using a full scale drawing

Close up

Used my Stanley #59 Dowel jig to make the holes

Had to make the ends of the spokes oval, gradually coming from a circle near the center

End of spoke after some hand sanding to complete the ovaling

Completed wheel in natural sun

Pair of wheels, one with secured hub