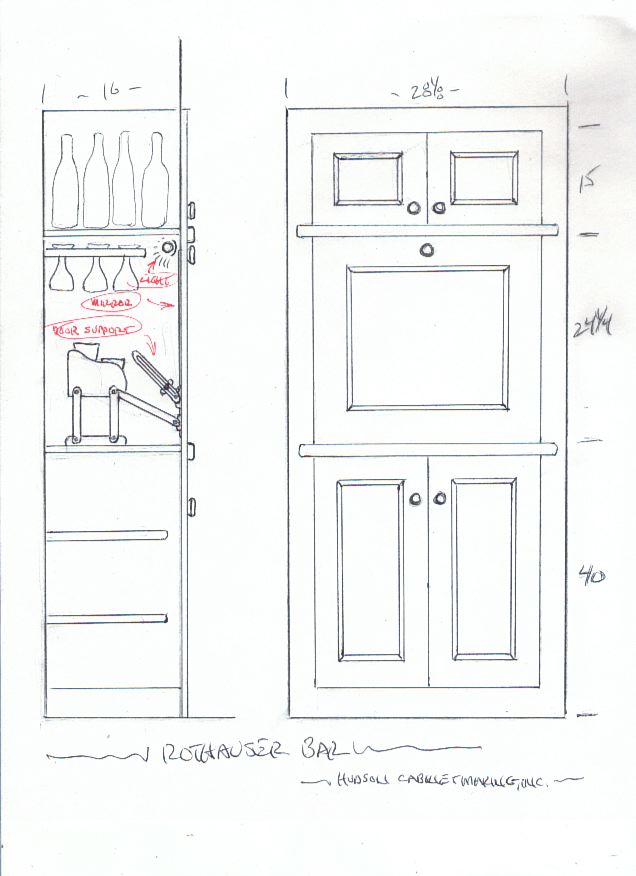

He loved this bar because, upon first inspection, it was all enclosed, but as you opened the front panel, which hinged outward and down, three things happened. First, the panel opened only 90 degrees so it’s back face acted became the surface to prepare cocktails on. Secondly, a clever arrangement of brass arms automatically lifted away the unit’s ceiling AND thirdly, also caused a tray of a dozen glasses to rise up and outward towards, what I’d imagined was, the tuxedoed host, serving his guests in some old, 1930’s movie. It was a very cool, old bar.

Right after their explanation and photos, they looked over at me and simply smiled. Following an uncomfortable silence, I said “aah… sure! We can do that”. Driving back to the shop, I thought of what might reasonably be done without subcontracting a machinist, mechanical engineer…and perhaps, a therapist.

It had to store SO many things…40 bottles of liquor and wine, shot glasses, scotch tumblers, wine glasses, AND…a wine cooler (and the stereo distribution amplifiers for the whole house that sat inside this closet already). I positioned the serving section half way up the opening (at standard working height) and let the above and below areas handle the storage for all the bottles and the cooler.

I envisioned a means of having the tray of glasses come out towards you as you opened the bar’s door panel.

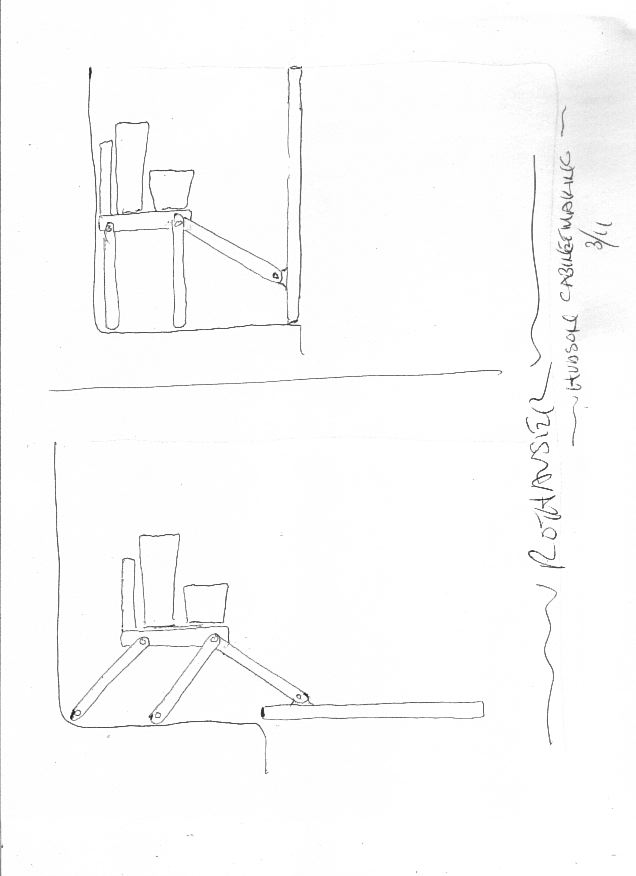

They liked the design and trusted us to figure out the mechanism. So we began. What was so great about their antique bar was how tightly everything fit inside when it was closed, but how easy to get to it all when open. The movement was relatively simple, but there were a number of requirements for this contraption. How far would the tray move when the door was opened? Would it miss the wine glasses hanging from its ceiling? The swing-down door was to have a mirror on its backside to act as a countertop to mix drinks on…which made it heavy. I found some adjustable tension, brass flap stays to ‘cushion’ the door from slamming into its open position (held at 90 degrees). I knew we had to build an operating model (wooden prototype) before committing to the actual construction. Here is my cellphone’s video of the mock-up.

VIDEO HERE

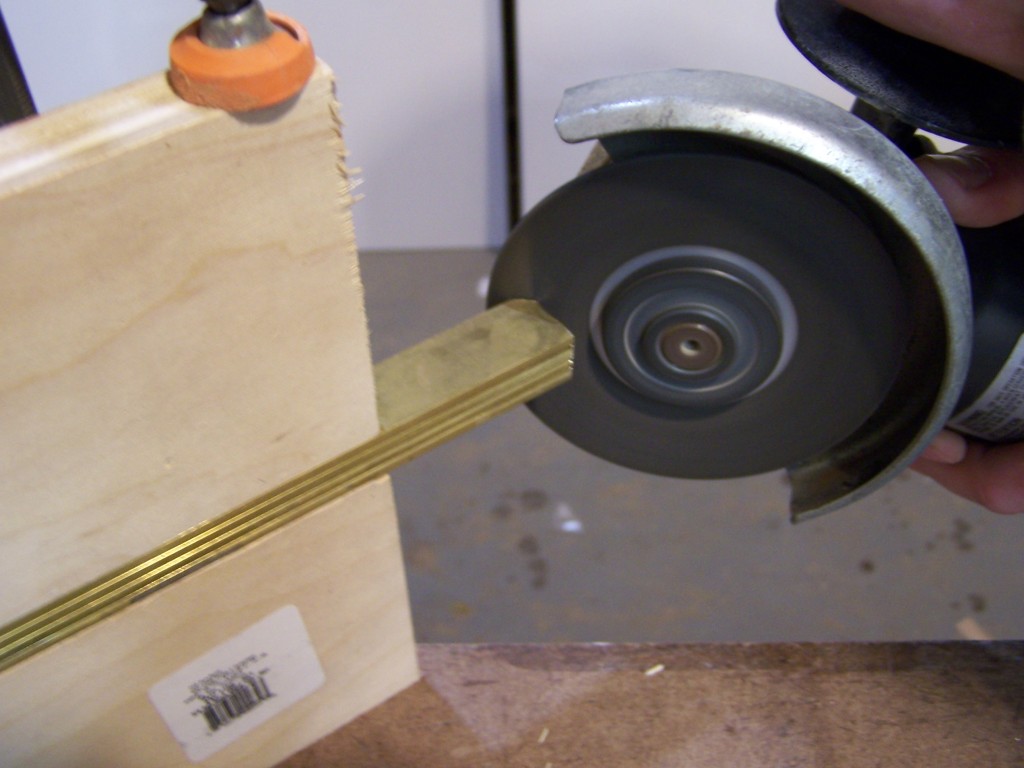

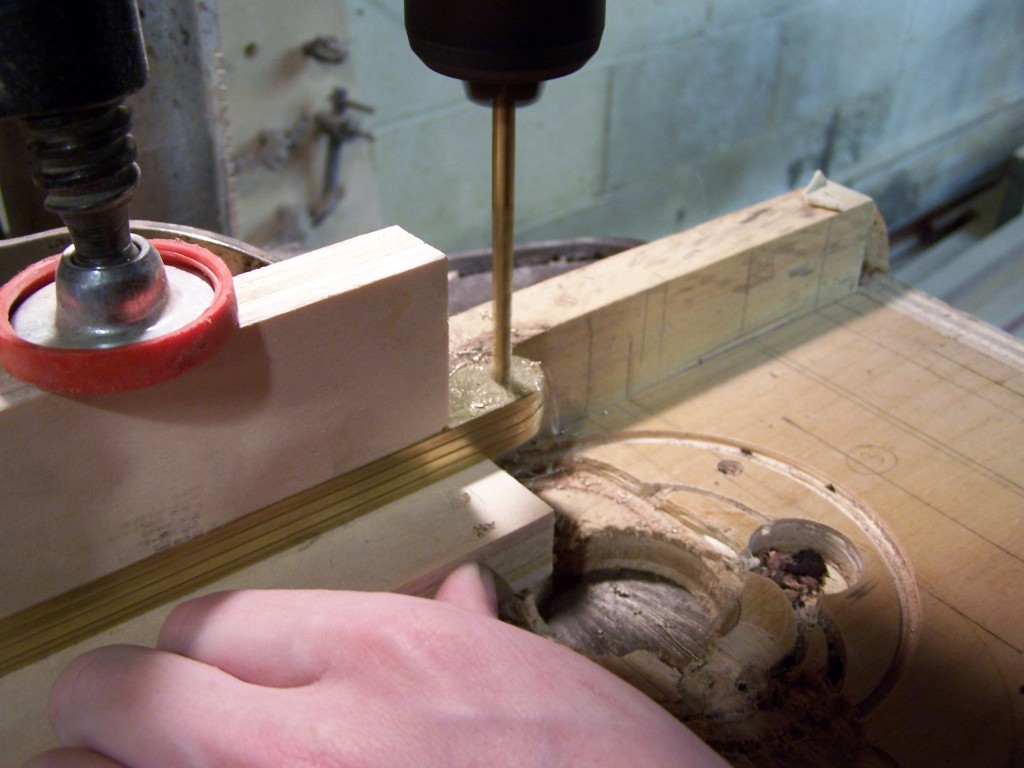

We adjusted arm lengths, pivot points, and the amount of tension until we liked how the mechanism moved. I ordered 1/8″ x 3/4″ brass bar stock to make our arms. It was soft enough to be a pleasure to work with.

Drilling the brass.

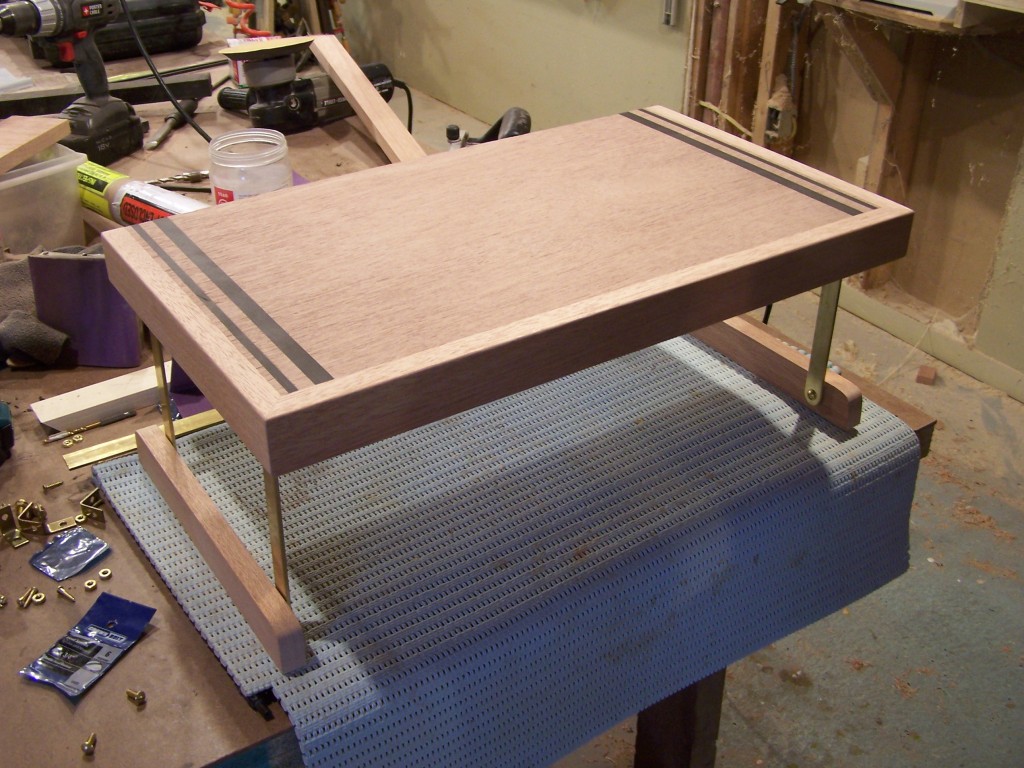

Next we designed a handsome, functional tray for all the glasses…in mahogany with thick, ebony inlays. My son (always eager to do finer, more intricate work) volunteered.

Here is a close up of the ebony inlays.

We created three tiers for glasses. Each glass sat within its own recessed circle, lined with felt. We made decorative side walls left, right, and across back.

Here are the three tiers for the glasses.

A brass lamp was mounted above. It illuminated when the door was opened. Here’s how the tray looked following its lacquer finish.

Because the closet’s interior had more room to the right of the doorway, we needed to create an extension that had to be removable during installation. The lower shelf configuration was also removable to allow access to the audio distribution system.

The wine cooler required ventilation…and with no other way to circulate air other than through the front, I suggested these little ‘jail house’ doors. This picture is from another project done a few year back.

We’ve done a number of projects for them (four of which are in a single room). Here is a short video of that room after all was completed.

VIDEO HERE

Hope you enjoyed this. Many woodworking projects on the website - check it out, if you'd like.