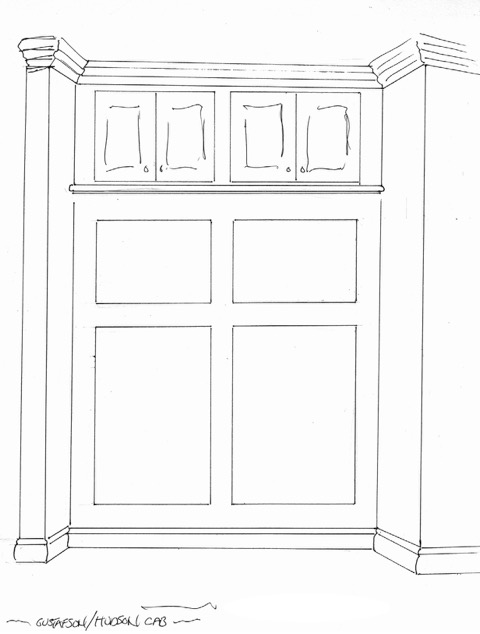

I did a simple drawing showing how I wanted the bed’s bottom to be paneled and included storage cabinets above as we had the room for it.

I usually build a piece an inch less wide than the spot it is to go…to compensate for inaccuracies in the walls, floors, and ceilings. I did some research of various hardware kits available. I only wanted the metal parts that allow it to swivel up and down and the mechanism to lock it into its closed position…with everything else about the bed custom made by us.

As small as I could make this foldaway bed to hold a queen sized mattress, we ended up with only an eighth of an inch on each side. Too close for comfort.

Here is a 17 second video of my son demonstrating how it works right after we installed. You’ll notice that the locking mechanism utilizes two small plaques that when lifted upward, not only unlock the bed from its vertical position but also act as support legs when it arrives at its horizontal position. So that the plaques looked like they were there for a reason, we mounted a clothes hook on each.

VIDEO HERE

We did three other, more interesting projects for him. I’ll post soon.

If you like our work, you might wish to check out our gallery at:

Hudson Cabinetmaking, Inc.