Basic Edgebanding Methods

Simple, low-cost tips and tricks for small-volume edgebanding work. April 16, 2009

Question

I am having trouble with iron on edgebanding. I donít do enough to justify an edgebanding machine, so I use a household clothes iron to apply the tape. I iron it on and then press it down with a piece of cold steel to try to keep it from lifting. Many times it will not stick well. I have tried to sand the edge of the melamine to get a smoother surface. It helps some, but I canít achieve reliable results. I am using the iron on medium setting. Any ideas?

Forum Responses

(Cabinetmaking Forum)

From contributor I:

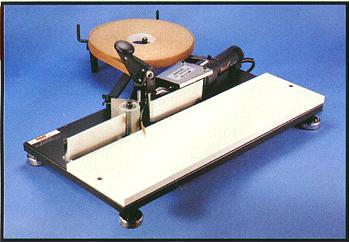

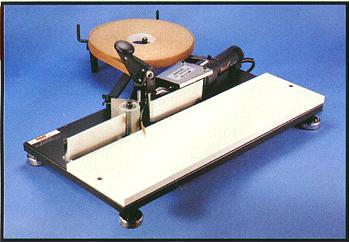

I'm in the same boat as you. I bought a Pioneer table top bander (Freud makes one too) for about $300. It works very well, way better results and faster than iron on. I just ran through about 60 cabinets with no problems. I made a jig to hold my gables at a comfortable working height and I then trim with a trim router and sand edges with a block. Looks like it came off a $50,000 bander.

From contributor R:

Don't use the cold steel to press down. Acts like a heat sink and draws away the heat you have applied. Edge banders have a heat sink roller after the pressure roller. Pre edgebander days I used a laminate "J" roller for pressure roller.

From contributor P:

I use a ski waxing iron made by Bakoda. Not sure how the temp compares to a regular iron. Run some tests on some scrap pieces with your iron at different settings, then check how well the tape sticks. After ironing, I press the tape down hard with a wood block that has the edge rounded a bit.

From contributor G:

If you don't edge a lot use the peel and stick from Fast Cap works great. I had the same problems. I would set the iron on high move very slowly and then rub it down with the edge of a piece of wood and some places still didn't stick. The iron on in my opinion is just not consistent.

From contributor R:

Set the iron on the high setting. Keep it moving quickly, The tape may curl slightly. Then use a hardwood block with a radius rapidly back and forth a few times flat alternately tipping on the edges, takes just several seconds. You are not using enough heat.

From contributor R:

Use the cotton setting on the iron.

From contributor Q:

At most shops the edgebander does not run all the time. I have had very good luck buying time on other peopleís banders. The time saving is huge. I think that you can afford to at least look into doing this.

From contributor B:

I do it just the way contributor R describes. Especially the high heat setting, and wood block for rubbing down. But if I had more banding to do, I'd surely look into that low-priced table top bander. I've had big automatic banders, and if you don't have enough volume they can be a real pain. Remember that the edge of the block applies much greater pressure than the flat; also, make sure the edge is clean and dust free.

From contributor S:

It could be your choice of edge tape. Try using a quality brand and see if that helps along with the tips mentioned above. Cotton setting with iron - wood block to press tape after heat.

From contributor G:

I am reading this thread with interest as I am about to apply pre glued edge banding (birch) for the first time. I will use an iron at a high setting as recommended, but I'm not sure what is meant when referring to a wood block with a radius. Do you mean a radius on the ends to avoid scarring the tape, or does the radius run the length of the block, leaving a longitudinal open tube effect? Also, is it better to trim the tape with a trim router, or one of those double sided manual hand trimmers?

From contributor I:

If you are using real wood banding I would use a trim router. If it's pvc any sort of razor contraption should work fine.

From contributor G:

That makes sense because I was wondering about the tendency for the banding (real wood) to split along the grain lines. The router will eliminate that problem.

From contributor R:

The radius on the block does two things. It will not snag the veneer but more importantly it transfers more pressure to fix the tape as it cools. Veritus used to make a handheld guillotine and a double bladed edge trimmer that work well. You can also stretch an 80 grit belt around a block, which works well for both end and edge trimming. One chopping blow makes short work of the ends and the coarse paper will quickly cut and slightly bevel the edges.

Click here for higher quality, full size image

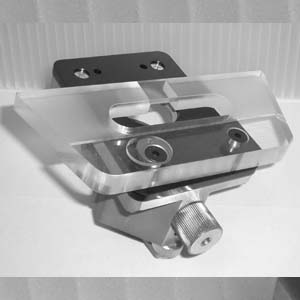

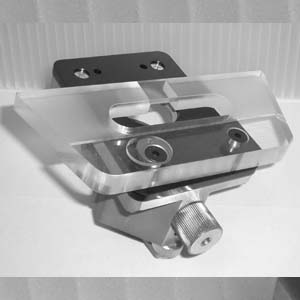

From contributor M:

I use this attachment for all types of laminates and edgebanding with excellent results, especially with wood EB.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor D:

We have been using EB for quite some time. We recently switched to Fastcap's pressure sensitive banding and got rid of the iron. I think that the glue is actually better. But in two recent projects, we ran into problems with the banding cutting and slicing uncontrollably with the grain into the front of the plywood box cores. We ultimately ended up putting hardwood cants in front of the banding in order to save the boxes (luckily there were only a few boxes in each project). I think that I am going to switch exclusively to using a palm router to trim the edges.