Question

About halfway through a job yesterday, I had to shut down my shaper. The vibration had just gotten to be too much. I knew I should have looked into it a couple weeks ago, but never found the time. So as I'm in the process of changing out the bearings, it has me wondering about a couple other machines that are getting up there in miles.

I'm wondering how other shops handle maintenance? Do you change bearings automatically after so many years? Or do you just wait until the signs start to show? I've always waited, but the problem is they never go at an opportune time. It's always when something has to get out the door. Of course some are much easier and cheaper to replace than others… tablesaw versus planer, for instance.

Forum Responses

(Solid Wood Machining Forum)

From David Rankin, forum technical advisor:

Maintenance is important. I maintain my machines every 150 hours of operation. As for bearing repair, most sealed bearings will run for 5-7 years without much concern. This is true if the tools are balanced. Bearings that have grease fittings should be greased every 150 hours or so. Bearings that have oil lines to them should have oil available at all times.

I have a couple machines I've owned for more than a decade without having replaced bearings, but they sound fine and are not daily machines, so I'm not too concerned yet. Alternatively most of the machines in my shop have been purchased used and as such I have no idea as to the age of the bearings. The biggest hurdle being that on old machines, it's not easy/possible to find out what bearings are needed until you break the machine down.

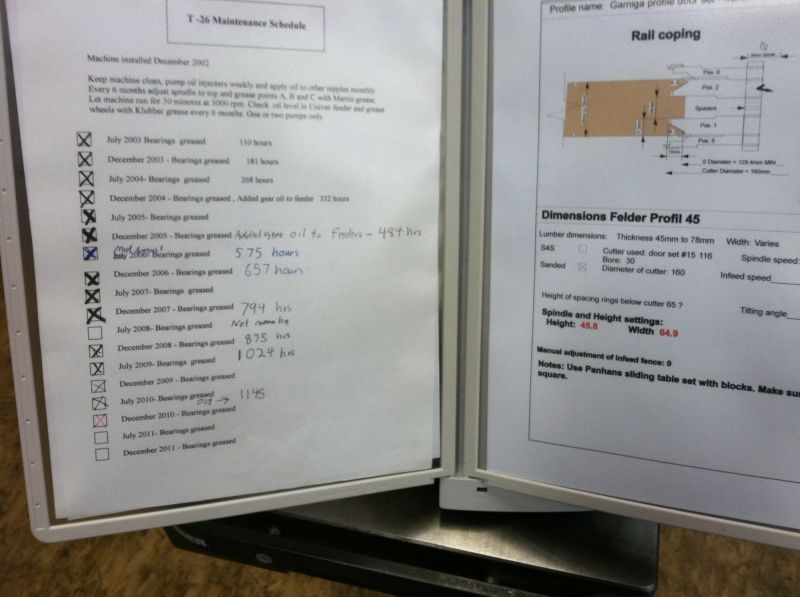

I think it's time to finally start a maintenance log. I want to be able to keep track of when I lube, what bearings are needed as I find out, and what belts are needed. I'm at a point where there are more machines than my memory can keep track of, so maybe this will help.

Performing basic lubing, etc. is better and will help you keep running longer. I would not skip this. You can also sometimes notice other problems when you do this.

In regard to bearings, you also get what you pay for. But you don't have to pay high dollar for a bearing either.

If a machine is going to sit awhile, I would apply some grease and run it for a few minutes. Let the grease get worked in and prevent rust and other problems from happening while idle. Belts dry out due to dry rot. Bearings will also dry out if they sit too long.

One important thing to remember: on precision bearings, only half pack them with grease. Over lubrication is one of the main causes of premature bearing failure.

Dave, I have several machines that are in the 30 - 40 year old range bought used several years ago and are still running great. The shaper that went down was a 2-3 year old Powermatic 27 bought new. Of course I don't think they designed these machines to be running 6" corrugated knife heads, so maybe I was asking a bit too much.

Anyway, bearings are changed and she's back in action. More importantly her replacement, a 42 year old Martin, is proceeding along and will hopefully be operational by the middle of next month.

My worry is with computers and electronics now that some of those machines are approaching 10 years old. I want to learn how to troubleshoot and repair these without complete (expensive) parts replacement. The techs tell me it's not that complicated once you learn the basics, but it's still overwhelming for me.

I have an 80's era Italian CNC drilling machine that is a huge time saver in my shop. However, if it ever has a problem it's essentially going to be a very heavy pile of scrap iron, as there's no support whatsoever for it. It has a floppy drive for saving programs. Anyone remember floppy discs? I haven't been able to get it to work right, so I'm limited to the 100 programs stored in it. Currently trying to get one of the pneumatic cylinders rebuilt and even that's been a failure so far. Replacement parts… I'd have better luck with a 120 year old planer!

This can have many factors, so let's assume that all of the tooling is correct and that no damage has been done to the spindle. Bearings come in different classes. The more precise the bearing, the better the lifespan, and the more difficult to install.

You cannot just buy the cheapest bearing, beat it in with a hammer, and run. The bearing life will be shortened. Instead, you need to determine the class of bearing. A good bearing house will help you with this. I use Motion Industries and Applied Industrial Technologies.

Also, you will need to determine the type of protection for the bearing (open, shielded, or sealed; single or double sided, or combo).

This is all pretty straightforward. Installation is where it gets tricky. There basically are two ways to install a bearing. Press and heat/shrink.

When pressing a bearing in place, you literally force the bearing to fit. The pressing action must be done on the race that is being pressed and not the counter race. Damage to the races and/or element can result.

When heat/shrinking a bearing in place, you will either heat or freeze the bearing to make it expand and contract. This movement will allow it to be slip fit into place. Sometimes it is necessary to do the opposite process to the bearing's mating component (i.e. heat a bearing, freeze a shaft).

Either way, you create stresses in the bearings and their alignment. To remove these stresses you must break in the bearings. To do this, first spin the arbor by hand to confirm it spins free. Then, using a motor of some kind, spin the arbor for a few minutes. Depending on the arbor, sometimes I can do this on my bench with a drill. Other times, I do this directly at the machine.

Rotating the arbor will cause the bearings to warm and heat up. The slower the rotation, the longer it will take, but do not exceed the unit's rated speed. Once the unit heats up, turn it off and allow it to cool. Then repeat.

This constant heating and cooling will cause the bearings to shift and move, helping to eliminate the stress of being installed. I use the following schedule on most class B and C bearings. Class A, I extend the schedule. Class AA, I do not. Too precise for my capability. This takes about 3 hours. 6 sessions of 30 min each. It is important for the unit to cool as close to ambient as possible. It may be necessary to extend the pause time.

1) on 5 min. off 25 min.

2) on 10 min. off 20 min.

3) on 15 min. off 15 min.

4) on 20 min. off 10 min.

5) on 25 min. off 5 min.

6) on 30 min. Then ready for production.

Keep in mind that when the bearing warms, it should not get more than around 100 to 130 degrees F. Temperatures exceeding this can damage the lubricants and the machine/arbor. Unless it is a motor bearing. The motor tag will usually state its nominal temperature.

I have read about freezing the shaft/arbor before and it seems like a common practice. However I've also read bearing companies don't recommend it, as the cold shaft coming up to room temperature could cause condensation to form between the bearing and shaft. They recommend instead carefully heating the bearing.

Like I said I'm still fairly inexperienced with installing bearings so just relating what I've read. As such I'll probably stick with the heating method for now. Luckily the bearings I've done so far (Unisaw/27 shaper) had small enough shafts they could be pressed slowly on a patternmakers vise. The Martin shaper bearings coming up next will not be so easy. Probably going to pick up a cheap Harbor Freight shop press for those.

I'm not sure how the letter classes translate to ABEC numbers? I'm planning on a 7 for the top bearing, and pending price I may try to save a few bucks on the slightly less important bottom bearing by using a ABEC 5. They'll both be open bearings and certainly the most expensive bearings I've ever done. Believe me there'll be no hammers used in this install.

It is also important to let your guys see you check the binder once in a while, and not just a week or two, but spot check it six months from now so they know it is not only important but mandatory. Have them turn them in monthly.

You can then document any repairs or tooling changes on that calendar and keep it on file. For example, we write down when we change out our straight line blade what blade came off and what blade went on, to keep a good rotation and evaluate our tooling vendor's performance. In addition, document when you changed a bearing, or belt, sharpen planer knives, etc. It has worked great and the maintenance is getting done as it should.

Find a good bearing house that you trust and use a screwdriver to check for possible problem bearings by putting the handle against your ear and the other end on or close to the bearing housing. You will be able to hear a growl in its infancy and prevent possible downtime or a missed ship date.

Editor's Note: Scarlett Machinery (website) is a top option for machinery sales and fast service / repair.