Bending Pressure-Treated Wood

Detailed, authoritative information on the ins and outs of bending pressure-treated wood for curved outdoor decks or garden structures. May 23, 2007

Question

Has anyone tried steam bending pressure treated lumber? I have a project that would require a radius of 36" and I could use a 5/8" thick board (nominally 1X stock). The problem is that I have yet to come across completely flatsawn boards to use. Most of the lumber I have inspected is riddled with knots, and I'm not sure what effect the steam would have on the preservative. Alternately I could kerf cut to achieve the bend. In this case I would use 5/4 stock. Is there a rule of thumb for the depth and spacing of the kerfs?

Forum Responses

(Furniture Making Forum)

From contributor K:

Steam-bending is not recommended for soft-woods.

From contributor J:

I build a lot of curved decks, and laminate the outer rim joist (the curved parts) using PT, usually 2x6 or 2x8. (All the other framing material is PT also). I hand pick each board looking for FOH stock with the fewest knots.

I have my local lumberyard bandsaw split the 2x’s in half (ends up ~3/4 thick) then run that sawed face through their planer a light pass to flatten it down to around 5/8 and make a nice glue face.

I like to let those split boards acclimate in the shade for a few days on stickers, then laminate them all up with Poly glue, usually PL Premium. I usually go with three or four laminations. I’ve never done a 36" radius though, but if I did I'd try splitting the board into thirds, then planing them down to say 3/8. I'd also bend them right up while still wet.

From contributor R:

Do yourself a favor, and use a good quality redwood for your bent parts. In my experience, pressure treated lumber is wood that hasn't even been dried, and when it does dry out, it will split, check and twist, and all your hard work will look like the type of wood that it is.

From Gene Wengert, forum technical advisor:

Another issue with PT lumber is that only the outside is treated. So when a piece is ripped, untreated wood is exposed and that can certainly be an issue. The PT process does make the wood more brittle. As PT lumber is graded based on strength, and small knots do not cause great strength loss, it is hard to find knot-free wood.

Knot-free wood is generally not treated and is sold at very high prices. Steam bending of softwoods is much more difficult than hardwoods. Note that if you kerf PT lumber, you may expose untreated wood. Also, you will need to collect the sawdust and dispose of it in a landfill. Do not let the dust fly around or get into the soil.

From contributor L:

We've steam bent PT Pine. Actually of the soft woods yellow pine is one of the best bending woods. However any exterior steam bent wood better be fastened/supported as it will tend to move with changes in moisture content.

From contributor K:

To contributor L: Do you dry the PTYP any before steaming it, or just use it saturated? Also, does it require longer steaming to get the temperature up all of the way to the middle?

From Gene Wengert, forum technical advisor:

To contributor K - the results you get with any wood and the correct or optimum moisture depend on the severity of the bend. 25 to 28% MC is ideal for severe bends and 15% MC is OK for mild bends. Because of the density difference within an individual ring in SYP, it is prone to grain raising during or after bending. Therefore, to achieve success on a medium to severe bend, bend so the quarter-gain is inside and outside and the flat grain is to the edges.

Joe Wood

From contributor J:

Gene, could you explain your last sentence a little better? I have a feeling it's a very important point about bending wood in general, and I don't quite understand.

From Gene Wengert, forum technical advisor:

When looking at a piece of wood that is to be bent, there will be four sides. Two of the sides will be flatsawn and two of the sides will be radial or quartersawn. A quartersawn face will have the annual rings at 90 degrees to the face. A flatsawn face will have the rings parallel or at 0 degrees to the face.

If you bend a piece so that the flat sawn faces are the inside and outside radii, then it is likely that the grain will separate. If you bend so that the flatsawn faces are the sides and the quartersawn faces are the outside and inside radii, then grain separation is not likely. (In other words, the best choice is to have the rings running from inside to outside and not edge to edge. Is this clear or should I post a picture?

From contributor K:

Thanks Doc. So choose quarter or edge-grain to the form. I'll bet that it would also be better to have slower growth pattern to reduce the size of the early wood as well?

What about my question of the bound water? It seems like it would take a lot more energy/time to get the temperature up all of the way to the middle, then there would be the hydraulic pressure within the cells, would it not?

From contributor L:

On a moderate bend as used on the edge of a curved deck moisture content is not critical. The wetter wood will take longer to stabilize, but sometimes this can be done in its permanent position fastened to the joists, etc.

On more severe bends hydraulic pressure does have an affect. It can work for you or against you depending on the situation. In some dense woods it will increase the chance of tear or breakage on the outside of the bend. On the other hand in some soft woods hydraulic pressure is an aid in avoiding wrinkle on the inside of the bend. All the severe bends I am referring to will require end pressure. Also keep in mind that moisture added through soaking and steam will leave the bent piece more readily than original tree sap.

From Gene Wengert, forum technical advisor:

By using wood that is 22% to 28% MC, you will not have any hydraulic pressure as there is no liquid water at these MC’s. For ring porous hardwoods, slow growth increases the percentage of earlywood compared to faster growth. The opposite goes for softwoods.

Hope this helps.

From contributor J:

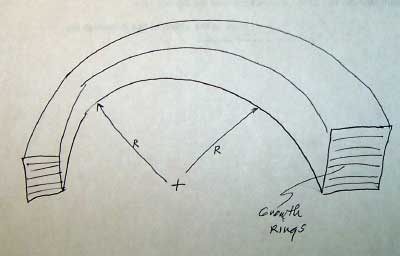

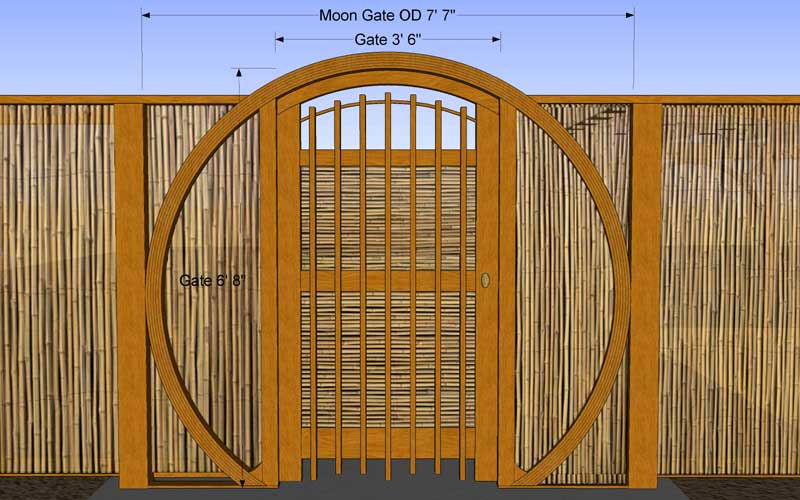

Gene, I have another question for you, actually two more! I'm going to laminate up a moon gate, using 6- 1/2 x 3.5" redwood. It'll be a 7'4" diameter circle. I'll be using plain sawn stock, this is the best bending grain isn't it? Also, should I put the barkside in?

Click here for full size image

From Gene Wengert, forum technical advisor:

I believe that you would be doing the opposite of what the picture shows. If so, I would worry about failures. On the other hand, a 7' arch is not too severe, so it may work well.

From contributor J:

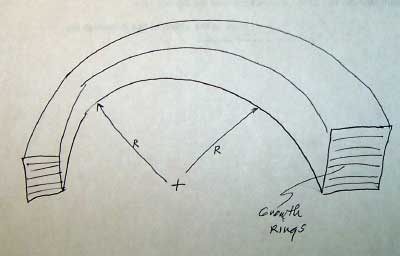

Gene, I’m not sure that you understood my question. I'm wondering if the barkside should be on the inside of the curve (like with this image below), or on the outside of the curve. Redwood bends so easily it probably isn't an issue, but I would like to know anyway.

Click here for full size image

From Gene Wengert, forum technical advisor:

I have never heard of a difference between bark in or bark out. But the best bending is if the grain is 90 degrees from that shown.

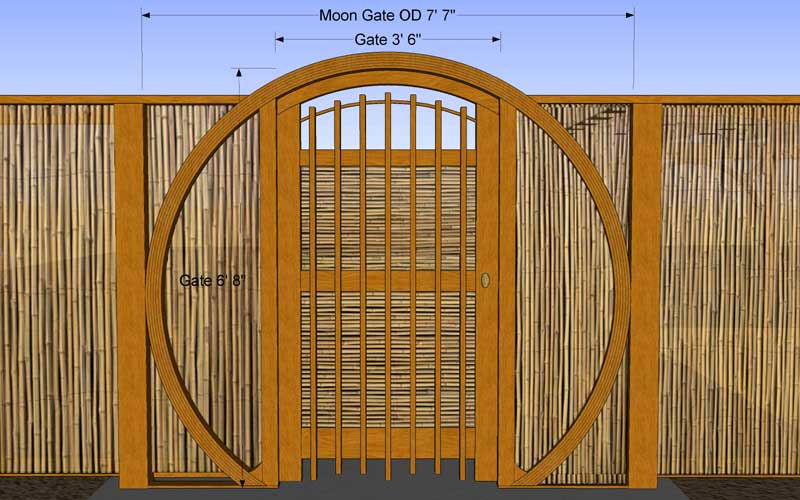

From contributor J:

Gene, I'll be starting the Moon gate soon and I'd like to clarify something before I start. Are you saying that a quartersawn 1x4 will bend better than a plainsawn one will? It seems to me that it's the opposite because plain sawn boards seem a lot more floppy and bendable than quarter sawn ones.

Click here for full size image

From Gene Wengert, forum technical advisor:

All the data and experience I have saws that there is no difference between q-sawn and f-sawn bendability, given the same thickness, width, MC, etc. However, the grain is less likely to separate with q-sawn, so it is preferred over f-sawn. Of course, if the MC is incorrect, the bend is severe and so on, the grain orientation will not help.

From Gene Wengert, forum technical advisor:

(Correction for above). All the data and experience I have shows that if you use f-sawn and the grain is perfectly parallel to the faces, which is not common with lumber that you buy today, it is less likely to have grain failure. For this reason, the "old guys" would split the log to determine the grain and saw parallel to the bark. They would then saw the pieces they needed with zero slope of grain (SOG). You can still see this being done at Colonial Williamsburg, VA, but it is rare in most other cases (although I did see it at McDermott cue and pool stick manufacturing).