I would like to tap the great minds of this forum with a question about managing volume. By the end of this year, we will be producing double the volume of a year ago, and last year we did double from the year before. In 2015 I would not be surprised to see another increase of 30% to 50%. To give an idea of the size of company we're talking about, this is an increase from 4 employees to around 16, and a 25% increase in square footage.

It's always about survival. When the economy was in the toilet, I worked 12 hours a day trying to keep the doors open, half my time on the shop floor. Now I'm working 12 hours a day trying to somehow produce enough work to keep the contractors happy who have been there to support me when times were tough for all of us. I don't necessarily want to get that big, but it is what is required to service the accounts that I simply cannot refuse work from. This isn't about making more money. I don't need to wring out more dimes. This is about meeting expectations. If I can do that, the money is beyond anything I need.

I am familiar with almost all of the philosophies - Lean, TOC, JIT, TQM, blah, blah, blah. What I want opinions about is what system, or elements of each system, can help the most with the management of rapid growth...maintaining system control when every aspect of the company is doubling. Design, engineering, project management, manufacturing, transportation, installation, and the 50 sub-categories within those categories.

I value your opinions.

From contributor Pa

Raise your prices?

From contributor Al

Eric,

A business can only support a certain level of growth based on cash and credit available. You need accurate cash flow projections and or credit to fund rapid expansion.

There are two common scenarios, the first is taking deposits so you always have cash but not making money, the second is getting paid on terms, making money and not having cash to fund operations.

Without an accurate cash flow analysis you won't know if the growth is sustainable.

You can also look at moving work out to longer lead times, tour customers are probably experiencing delays from other subs.

There have been a couple of articles recently about developers delaying schedules.

So extend schedules, manage cash, and raise prices to cover additional costs or be near market price.

You can also run a second or split shift if you have the personnel but that consumes cash faster and allows invoicing faster.

A-

A-

From contributor ka

Really ?

From contributor Da

As Pat suggested, raise prices. Do it slowly and quietly.

It will take a while for that to get the desired effect, so in the meantime, you need to delegate responsibility, and develop a method of accountability for that responsibility that you are doling out. Make a plan of what needs to be done in the next year, and then break it up into steps that you accomplish each month or so. There are some office tasks that can shifted/subbed out of the office - bookkeeping, payroll are two.

I managed a shop with 50% growth for 5 years. It was all about equipment at first, then employees, then space, then more equipment again, then more employees, then space. I had a separate sales staff and bookkeeping, so all I had was production. We built 4 shop spaces in 5 years, and had 200K a year for equipment.

From contributor Ji

Eric, glad to hear of your rising sales.

I have been experiencing growth of +30% year over year for the last three years. What I have learned to do is to change my personal work. I am now doing more directing instead of actual production as during the years previous. Hired a production manager to over see the production underneath my supervision. He takes care of the details of the work flow, problems and some scheduling. I have my hand in overseeing the big picture of production and scheduling what jobs are being worked. This has helped as I now have the time to figure out how to overcome some of the bottlenecks that have become more apparent due to increased work.

I have also added another cnc to handle the volume and will be starting a second shift this fall when the volume picks up. I have already identified the person to be in charge of the second shift and am working with him to understand more of the nuances of the operation.

I have been spending more of my time in sales and customer contact with my outlets.

This has actually been helping in getting more sales.

From contributor ca

It might have something to do with the parts you think are working.

From contributor Er

So, the suggestions are:

-raise prices

-extend lead times

-manage cash carefully

-run a second shift

-delegate responsibility (maintain accountability)

-make a plan, break the plan into steps

already done, done, done, done, done, and done. But we're still growing. At least I know I'm on the right track.

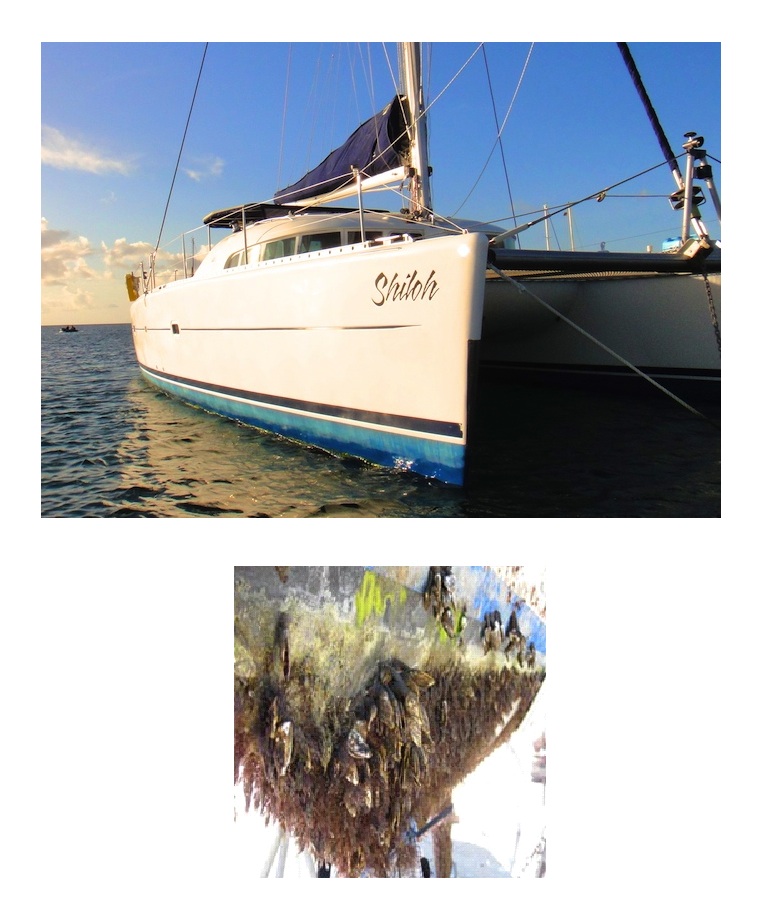

I was half expecting the obligatory post about how the implementation of Lean will free up extra capacity. Instead I got a picture of some barnacles insinuating there are things that I THINK are working but in fact are NOT working. I suppose that could be true.

Alan, David and Jim, you three seem to be already at, or have experienced the volume I'm talking about. And I don't recall you guys actively engaged in the useless debates about Lean Manufacturing that goes on here between the owners of the 3 man shops. Is that because you don't believe in it, have already done it, or have something else? What would you describe your management systems as? Your manufacturing systems? Do you follow an acronym philosophy, or something else?

What if we just steer this conversation into the realm of what it takes to manage a 20 man shop, with contributions from guys who have actually run 20 man shops. I rarely see those kinds of conversations here.

From contributor ca

Eric,

Could it be the pejorative "blah blah blah" is itself a barnacle?

Maybe the answer(s) really does live in one of these acronym philosophies. But maybe not. Your business may be special.

From contributor Pa

I have run a 20 man shop. I would have done better if hires 16 through 20 had been in the office, not on the shop floor. Doubling volume is a challenge, doing it two years in a row means that your systems for scheduling, costing, and general shop communication are probably lagging way behind the curve. Also: did you double new contracts or actual output? If you have doubled output two years in a row, maybe you should be giving the rest of us lessons.

From contributor Pa

I have not run a 20 man shop.

But since my experience is in the store fixture business, I bet that I fully understand your feeling of can't hold on and can't let go.

Until you have an organization chart with people performing the functions that Have to be performed you will last about as long as the average meteorite flashing across the sky.

The hard part about this is that they have to be trained to perform that function. And they have to be trainable.

This is damn hard and not malleable to some glib statement. But unless you do this you will not last.

From contributor Ji

My operation is a 10 person shop. Before going out on my own, I ran a production plant with 90 people, so I have a little experience with multi-employee operations. Your job is now changed to management rather than production. You need to acquire different skills if you to. I attend management classes at the local community college night classes every year. Helps me keep from forgetting what I already know.

My management style follows another acronym: KISS. I try to keep it simple and stupid. Yes, this does involve a lot of the LEAN, 5S and other styles. But I do what makes sense to me and my employees. If I can't explain it to them and they understand in a minute, then it is too complicated. Make it simpler.

I let everyone know theirs and the others responsibilities. Everyone knows what work is to performed by the other people. By doing this, the employees become self monitoring as they know what is expected and they know that everyone else knows as well if they are doing their job or not. I do ensure that the work is being done as expected. If I see someone not getting it done timely, I jump in to help and start asking why they are behind. This way they know that I will help them and that I want to help solve what caused the problem. My production supervisor does the same as well but I have his plate full of work as well. You can get insights into problems when you are there with them to solve the issues.

My production line is divided into steps. Each step has to be done before the next step. My employees know that they have to complete their part for the next person to do their part. The person waiting on the first person wants them to get their job done promptly so they can do theirs.

Every morning I talk with each person about what is added and /or different on their work plate today. Keeping the lines of communication flowing both ways is very important in managing. Organizing the shop flow, people, order flow, sales flow and other things is my job now.

I hope this is helpful.

PS. Ignore the people and comments who do not contribute to this discussion. They are just looking for attention without adding any value to the discussion.

From contributor Po

Jim,

So there was something you disagreed with about the sailboat photo? I thought it was very succinct (lean). At the risk of calling even more attention to my pointy-headed learnedness I would like to pass along two more observations.

You wrote: "Everyone knows what work is to performed by the other people. By doing this, the employees become self monitoring as they know what is expected and they know that everyone else knows as well if they are doing their job or not. "

About ten years ago the Harvard Business Review published an article called "Decoding the DNA of Toyota". They asked the poignant question "How does the worker know when he is doing his job correctly?". This is a fair question. When you look around the average shop you see people doing the same job several different ways with several different results. Some of the people are a lot faster at what they do.

Eric has a problem keeping up with demand. It seems to me that anything he can do to lubricate this process is going to help. One of the ways to do this might be standardizing best practices and developing a mechanism to certify that people follow them.

Eric, you led into this thread with the statement you were only interested in learning from those who had "been there, done that" and you had no patience for the bullshit acronyms.

My question for you is a two part one: Can you cogently explain what the principles of LEAN thinking are.........and IF you can do this can you please explain how these principles would not apply in your circumstance.

Coincidentally the same Harvard Business Review issue (Sept/Oct 1999) that published the article about Toyota included a first person account by John Peterman of the J Peterman Catalog company. He explained exactly why his company grew so fast and flamed out so quickly.

1) He strayed from what he was good at.

2) The company grew faster than management systems could support.

3) He failed to communicate his vision in a way that was useful to others.

But then again none of that is germane to this conversation, is it?

From contributor Da

Eric - I ran a 20 man shop doing residential architectural. I focused on Production, and always felt I was 2-3 steps behind where I wanted to be. The upside was it was never boring, always a challenge and the growth felt good. The downside is that there rarely was a break, and I often felt I was inadequate. My boss was supportive, however, and the cash to fund expansion was always there, and the sales were there on the other end.

I learned first to let go my worries about getting the job done, or turning down work, and would plunge headfirst out the airplane door, checking for the parachute as I went. I could always draw resources from around me to make it happen as it should.

Years later, I ran a 10 man shop of my own, until the Crash in 2009. We did/do custom work of all sorts, and no real production work at all. Jobs ranged from 5 m/hrs to 1,000 m/hrs, and all time and materials were tracked to the job. I spent a third of my time estimating, a third on 'autopsies' (examining completed projects to see how they compared to my estimates) and a third worrying about what else I should be doing.

I did no shop work at all in either of these jobs, and grew to see my function day to day as a facilitator. One that supports the production in every way - processes, equipment, training, development, materials, etc. It was nothing to spend a day or 3 moving equipment and working out details for better flow, or to see if an employee idea could work.

I have never subscribed to management by acronym, though I could describe a strong push for constant evolution - where every step and process gets re-examined repeatedly to see if it can be eliminated or improved upon. Once the employees get it, they feel free to make suggestions and go along with the periodic changes, or attempts at improvement.

From contributor Ji

Pointy, Part of my version of KISS is that it is done the same way every time. This results in steps not being missed and quality level remains consistently high.

I have created booklets that cover the step by step procedures as well as videos of the procedures. This is part of keeping it simple. When a new person is brought on, we demonstrate the whole process and then teach them one step at a time. Keeping it simple. As they master a step another is added.

There are many nuances to the way that I manage. I look at myself as having many different roles. Cheerleader, assistant, visionary, supervisor, owner, sales, coach, thinker, searcher, etc. The list is in no specific order as how I distribute my time. I have found a system that works for me that I created from the many different courses I took, supervisors I worked under and with, formal corporate training programs and employee feedback. I am not saying it is the best as I am always a project under construction (ask my wife). I am saying that it works for me. I do not believe in trying to push my method on others. I just relate what works for me.

The other part of why I work the way I do may be the product line that I make and the systems that I have in place. I create personalized puzzles, puzzle stools and other personalized items for children and adults. Even though each one is made to order, there are a lot of similarities in the product line.

From contributor Po

Here's an article about how one company was able to increase capacity without spending a tremendous amount of money.

From contributor Al

Eric,

We have been doing a hybrid of lean since 1991 when we went to a fungible manufacturing system with re-locatable assembly and conveyor lines. My primary complaint about current lean thinking for custom make to order that are selling to contractors with a fixed billing cycle and a fixed delivery date is that any inventory that builds prior to shipping and the GC's invoice date that doesn't affect invoicing is not a goal for us (WIP) or overproduction. we try to manage assembly shortly before delivery but if we are slow we will build to inventory to keep employees busy.

I took an AWI class on cash management in the late 80's and then my bank required my to take the same class only a 3 day version. Cash is the life blood of your business, it must be managed correctly and you need to understand and solve cash requirements before taking on contracts and expanding.

Basic theory is if you make a 10% profit you can sustain about 7-9% growth if cash flow remains constant to sales.

You can try and change your terms with your vendors to go to net 60 which cycles about when GCS pay relative to when you purchase.

Our biggest growth spurt was 3.75M in sales produced in 12 weeks. When I went to discuss terms with the customer they didn't want a large invoice from me at the end and wanted to pay every 2 weeks, so they basically sent a 500k check every two weeks. That solved our liquidity questions.

A-

From contributor Er

Thank you everyone for your responses. I am listening, but I can't formulate a response because I haven't come up with any more questions and I haven't come up with any answers. I do appreciate the feedback,

Eric

From contributor Jo

I'm with Jim on this .. start building processes and consistent methods in your company and focus on problem areas first.

It's tough also, in your position, but you're gonna have to delegate more. To that end, developing processes you can control rather than relying on individual's skillsets is a good direction to think about.

As always cash flow management is number 1.

From contributor Pa

I forgot to mention the name of the book is E-Myth.

From contributor La

That is a tough rate of growth. Cash flow @ that rate?? I don't know your customer's payment system but if they are the typical GCs figure 60 days! Before the crash we had hit 24 employees. Lots of work but too many problems finding qualified help. I had manuals with series photos for most every operation, helped "some." Took a lot of time up dating.

Currently have 16 and life is better. Cash flow has evened out, good employees, still have problems with maintaining even sales. Too many peaks, one on top of the other. I'm with David on "I have never subscribed to management by acronym, though I could describe a strong push for constant evolution - where every step and process gets re-examined repeatedly to see if it can be eliminated or improved upon. Once the employees get it, they feel free to make suggestions and go along with the periodic changes, or attempts at improvement."

At one point my employees suggested I put everything on wheels, the equipment got moved several times. Adding, updating, improving flow. Best thing done to improve flow was setting up conveyor lines for panel processing area. Breaking big jobs down into smaller batches. Created a doweled case production cell. CNC'd & banded parts in, finished case goods out. We've managed to do as many $ in sales with lots fewer employees and constant improvement in methods.

From contributor Pa

I don't see where Eric said he is doing commercial or residential?

If the latter the cash flow problem should be irrelevant.

From contributor La

Not so sure cash flow is irrelevant, even though probably easier in residential. I've seen residential shops go down around here from lease/loan payments when work slowed. That might be called under capitalized, which is also a common problem in this business. That probably applies even more to rapidly growing operations. I think few people realize how much operating $ it takes for day to day running a business. Hope for the best, plan for the worst.

From contributor Al

Larry,

I think Pat is assuming that residential jobs can get deposits so there is increased cash available when work increases. If the shop has 30 day terms with vendors then they are getting operating capital in advance of work. This is the issue I tried to point out that can create a mirage of profit, the ability to pay bills in a constantly increasing work load as cash is increasing but as soon as work slows or stops there is no cash around because there were no profits, only cash. Each month loss is covered by the next months cash deposit.

I spoke with a vendor yesterday that quoted some material to me, he knew the retailer and told me a story of a shop that was buying 1 million a month in materials for over 5 years for 1 customer, at the end they filed chapter 7, they always had money until the work stopped. Either there were no profits or none of them stuck and were preserved for working capital.

A-

From contributor pa

That is what irritates me about GCs . 2 to what 20% of the money on a job is thier's yet they make us sweat bullets over cashflow. They can be technically BK for years but skate because they can use other peoples money.

From contributor La

Cash flow when work slows is tough if you aren't prepared. We should operate like McDonalds or Dell. $ up front, pay vendors later. I've seen a lot of small kitchen shops decide to go into commercial work when residential slumped. Rarely worked.

We do a lot of work for a multinational with HQs outside of the US. Contract calls for payment in 90 days. They ask for 2 week or less lead time! You don't have to be insane to do this kind of work, but it helps.

From contributor Al

Larry,

Many corporations have policies of taking cash discounts, just offer a 1 or 2% discount for 10 day payment and see what happens. Some GC's that are well funded will take advantage of a 10 day discount.

A-

From contributor Pr

Eric,

As a vendor of scheduling software, I would like to talk about a complementary approach.

High-variety production can be more efficiently managed when we have reliable prediction of workflow, bottlenecks and project (job) completion times, capability to perform quick what-if analysis and proactive capacity planning. Based on advanced calculations, powerful scheduling software support this functionality although they demand a good amount of job status information. They not only generate schedules at operational level on a daily basis but also serve as an intelligent decision support tool in controlling and managing high-variety production. They clearly show how much workload can be managed when all resources are optimally utilized as a group with proper synchronization of production operations and material supplies. They also help assess the potential benefits of partial outsourcing of workload when volume is high.

Such tools facilitate prediction-based production management and help improve on-time delivery, throughput, WIP and project lead times.

From contributor La

"although they demand a good amount of job status information" And therein lies one of their major costs. The person/s that have to manage/gather all that information has to be someone with considerable knowledge of the entire plant. I.E. a valuable employee/owner. We tried it, too much time. There are simpler, accurate enough solutions for a small shop. The high variability of store fixture work keeps the various forms of CPM in a constant state of change. The work center overlaps could be very different from one type of product or volume to another.

This is a good subject to consider as a shop moves up in scale. The trade off of the various costs may make the shift to software worth while. For now, in a small shop with just 16 employees, KISS!

From contributor ca

Prasad's approach is predicated on predictability. The computer model only works if you can depend on the inputs. You have to have confidence that something which took 20 minutes to do last time around will take 20 minutes to do this time.

A lot of the success of each operation in our shop is dependent on who is doing the task. If the process is part of a chain of events then the whole chain will be affected by variability in one link.

The priority therefore becomes how to standardize the outcome, (i.e., standardize the input). But standardization is one part of one of those bad acronym programs so maybe we stay with the cowboy approach?

From contributor Pr

Larry, many job shops develop, for every job (project), routing details that include all relevant operations, estimated process time for each operation, dependency relations among operations and resource and material requirements of operations. This job information is critical for running scheduling software and is generally available in many job shops which use an information system, at least in Excel form. Some shops maintain this information even in MS Project. As time goes on, there will be some progress on each job in production. The scheduler is required to update progress on each job before revising the overall production schedule. For a shop with 16 workers, updating job progress may not take more than 20 minutes for schedule revision when workers on shop floor provide the necessary information. Normally, I recommend such schedule revision once or twice a day. I transform the total production schedule into dispatch lists for resources and advise them to follow the sequence of operations given to them as much as possible on each day without seriously bothering about the scheduled start and finish times of tasks. This practice will absorb a lot of variation in the system. In many shops, the benefits from workflow prediction, what-if analysis and proactive capacity planning may far outweigh the time required for updating job status information.

Cabmaker, for adopting this approach, it is not necessary to feed very precise estimates of task durations to the model and have very high precision in workflow prediction. Ultimately, the level of precision in workflow prediction should give us useful guidance in production control and management. In my view, the most important elements of workflow prediction are the start and completion times of projects. I would not look for very high precision in the start and finish times of individual tasks of projects. Our finite capacity model allows some level of uncertainty and natural variation in the system so that the projection of start and completion times of projects are more dependable. The prediction must be revised when major changes occur.

You said, "If the process is part of a chain of events then the whole chain will be affected by variability in one link.". I agree with you. In spite of this phenomenon, we should be able to predict project completion times (not the task completion times) with some degree of confidence.

From contributor pa

Prasad

Could you explain the difference between what you advocate and takt tme?

From contributor Pr

Pat,

As I understand, we would tune the production system to maintain an appropriate, smooth production rate for meeting takt time set by market demand. It is more relevant to low-variety, high-volume production systems. In custom manufacturing, the demand is not so smooth that we can easily adopt production control based on takt time. In this environment, the nature (work requirement) and timing of customer orders are highly unpredictable and production systems are mostly driven by specific due dates and therefore, we cannot smoothen demand to have production control based on takt time. When a variety of jobs (with generic precedence relations among their operations) are to be made by respective due dates using a fixed set of resources, many jobs simultaneously flow through the system competing for bottleneck resources. It is not easy to predict workflow for these jobs even if natural variation is very small. The limited resources, precedence relations, the variety of jobs and simultaneous flow of several jobs make the prediction very difficult. Custom job shops cannot smoothen demand like Toyota because they do not have dealers who can maintain large inventories.

From contributor Pa

Tim

What is your take on Prasad's thinking?

From contributor ca

Pat,

The logic to Prasad's system is pretty hard to beat. What I think most of us struggle with is the implementation.

He is right that the benefits from formalizing your work processes far outweigh the costs of doing so. Even if you don't know how long individual things will take to do, or if they take differing amounts of labor depending who does the task, you will still get the overall project done sooner by just formally listing out the optimum sequence. It's kind of like the difference between navigating to an unknown address using the ever-descending circle system vs googlemaps.

If you write it down great things happen.

If your method of task management relies strictly on imagination, powers of observation or brute memory you're going to go through more groceries between now and the finish line.

From contributor La

I totally agree with PVs last post. & like cabmaker, believe the devil is in the details of implementation. There is something wrong with people that want to be in the highly custom, higher risk woodworking business. In my struggle, having that mental illness, I've attempted to reduce the variables. For boxes that's pretty simple. For curves it can be reduced but still wrapping curved casework around electronics, money dispensers, chillers, warmers, various dispensers, insurance company requirements for jewelry cases … on & on. The slightly more sane people restrict their production to a very limited # of the above. Here we have to feed the beast. Devise ways around constant change orders, shifting delivery dates and designers that want it their way even if it won't work. Software that would fix all of that would be great if the software was smart enough to estimate the various time, cost, order of work, overlaps … & didn't take much valuable time away from the most highly adaptable employees in the shop!

At one point I bought a piece of software that could optimize work flow, schedule etc. It took an immense amount of setup/input time, constantly. It would have been great for a shop doing limited variable, high volume work. If a shop is big enough to require that level of output, go for it. I've opt for the KISS principle, reducing variables in the system, cutting batch sizes to less than 4 hours per process, eliminating designers that can't get it, etc.

From contributor Pa

Smoothing demand is a great point. Residential can smooth demand as most likely you have to figure out where to warehouse the cabinets as you are ahead of schedule. Where as commercial is the opposite.

Nobody is going to have trouble scheduling boxes. On the other hand if you have a reception deskp/nurses station/cash wrap to do it won't take much to schedule the cutting as it is going to be rough cutting. The rest is going to be final assembly/laminating/trim cut and will vary a lot depending on the details. Because of this it seems to me that a macro metric is more accurate?

On the other other hand South West airlines does a pretty good job filling seats by saying 1st come 1st served. Or where I learned some profound knowledge "touring" a brewery in Tim's neck of the woods where the "docent" said just bum rush the serving counter as that is what works best. Prasad what do you say to those who prefer the bum rush technique?

From contributor Ja

Good thread.

We too are going though some pretty monumental growth from a little 2-4 man custom shop, to 7-8 here in the last few months, including moving our operations. While we have a cnc and already outsource doors. For some of the relay hard spots and deadlines (especially when we were closed while moving), we utilized the finishing capabilities of our door vendors. This was big. It allowed us to meet the demand, with our existing resources (the finish booth is our biggest production constraint, and took the longest to get back on line). I was even considering outsourcing box parts as we almost got to the point where our cnc (or the operator) was a constraint.

From contributor Pr

Pat, if they are comfortable with "bum rush" technique while satisfying their clients, I have no objection.

From contributor Pa

Prasad

In order for your system to work you have to input data regarding the process times.

The problem is that a product like a cash wrap will entail many different tasks that are going to difficult to determine for time spent.

In order for the data to be useful it would have to be relevant to a certain task, other wise you are going to just have data for a reception desk which may vary in hours from 50 to 500. This would not be useful in predicting the schedule.

From contributor Jo

Pat

If you bid your work using material and labor techniques then you DO have the data for a simple schedule that relates to production and allows you to do the things that Prasad is talking about. Our estimating system breaks labor down into the processes and mostly automatically.

Most importantly, then you have targets for profitability that you use to control projects. IE, a reception desk had 4 hrs cutting, 3 hrs laminating, 26 hrs assembly, 8 hrs finishing, 2 hrs inspect and package, 3 hrs placement on jobsite, 6 hrs install. So with that data those amounts become targets and you use those targets to schedule with. If you hit the targets you made money.

OTOH, if you take the time to record how long it did take to produce the reception desk but then have no direct relation as to how the item was priced you still don't know if you made money and where in the process you went off track.

Now for one reception desk this is not such a big deal. However when "wing it" day in and day out you really don't know where you are till a full company wide analysis is done. Thus you are flying while blind.

These are all reasons why estimating HAS to be tied to production and you need to do material and labor based estimating. Every project is different and has to evaluated in reference to it's sell price. It's not that hard and there are a few programs out there, not just ours, that even make this the easy way to do things.

From contributor Pa

John

With all due respect, I'm painfully familiar with minutiae of it all. I use the same software Larry does albeit scaled down.

Your characterization of "4 hrs cutting, 3 hrs laminating, 26 hrs assembly, 8 hrs finishing, 2 hrs inspect and package, 3 hrs placement on jobsite, 6 hrs install."

Is not adequate to take the information and project forward with any accuracy.

Boxes are not really a problem. The problem is with the infinite variables on custom commercial work. On that reception desk is it canted? Does it have stand offs? Electrical? Does it have quirks? Are they painted or stained? Can the job go up in the elevator or do we have to go in from the outside with a crane? Is the designer going to reject the material because of some subjective reason? Is the building going to have proper moisture content? Is the shop builder going to break down these tasks while switching back and forth from one task to the next? etc., etc., etc.

From contributor Pr

Pat,

You raised some interesting issues that can pose problems in scheduling. I agree that the information about task list, estimated durations of tasks, precedence relations among tasks, resource requirements of tasks and resource availability is not sufficient to perfectly model a production system. It is very likely that many variables like those mentioned by you are not directly taken into account in planning and scheduling. However, we incorporate some optional buffer time in finite capacity schedules to deal with natural variation in the system. The selected level of buffer time varies with production system. This is not the buffer time that is simply added to the predicted job completion times. We deviated from the standard finite scheduling in this sense. You would not find such buffers in schedules generated by other finite capacity scheduling tools. This buffer is also different from the buffer in Drum-Buffer-Rope (DBR) method of the theory of constraints.

For many systems, the job waiting times that appear at bottleneck resources in our schedule can absorb the influence of numerous unaccounted variables and give a reliable prediction of job completion times. As I said earlier, prediction of start and finish times of individual taks may not be very reliable due to natural variation. I usually advise people to try workflow prediction (based on powerful scheduling tools) on a trial basis and see its merit for their system.

Sometimes, it is better to try a new idea or method instead of maintaining pessimism. If it does not work, you may not lose much.

From contributor Pa

This is not the buffer time that is simply added to the predicted job completion times. We deviated from the standard finite scheduling in this sense. You would not find such buffers in schedules generated by other finite capacity scheduling tools. This buffer is also different from the buffer in Drum-Buffer-Rope (DBR) method of the theory of constraints.

What is the secret sauce? Or is it secret?

From contributor Pr

The buffer time that I am referring to is different but not secret. It is illustrated on our web page shown below. We call it lean schedule in job shop and multi-project environments.

From contributor Jo

Pat

I wasn't referring to box work in my post but aside from that what's the problem with material and labor estimating and then using those estimated values to set schedules and profit points?

Yes, all those variables you listed, (standoffs, fitment, etc) need to be allowed for. That's what estimators do, or should be doing. Where is the difficulty in that?

It's when you don't do material and labor based estimating that things get complicated because critical questions haven't yet been answered, yet your price has been fixed. These problems are then passed thru to a project manager or whomever to try to make it all work out.

I would suggest that's it's easier to run the business using material and labor goals from the estimate than it is to use fudge factors or "winging it for pricing".

Estimating should not be about determining a sell price .. it should be about determining the cost to build the project. Perhaps this is a subtle difference in some people's eyes but one way gives you nothing but a price and the other establishes profit setting goals for production.

From contributor Pa

John

The numbers you used implied round numbers that would not correlate to minutiae.

The problem with tracking these numbers is assigning the minutiae to the job and then getting the data as the job is being worked on, E.G. typically you would have one guy working on the desk he would then work on assembly mixed with laminating mixed with trimming pieces for final fit mixed with sanding mixed with installing the risers.

It is not practical to have someone separate those tasks when recording time. You will say we will then use the same proportions from the estimate and apply them to a lump sum for the above tasks mixed together.

That may be doable, but the reality is that I can get a more accurate idea of how long the job is going to take by using macro data, or as you say "winging it".

From contributor Jo

Pat

Certainly "winging it" is your choice, but that goes quite a ways as to explaining why you cannot schedule your plant floor.

How you run your own plant is your concern. Declaring it to be the best way or even as a desirable way is a bit disingenuous though. Reflect on the limitations it creates in your own business management in that you don't have data to schedule with, nor perhaps have a good idea as to your cash flow needs as well.

How much of your sales are materials vs labor? I'm sure you can wing that too or use a historical average. However when next month's work involves a large amount of material cost vs little labor sales will you know about it before it hits or will you pay for labor you don't have sold and struggle to find that extra $50k that those material purchases need?

I'm not trying to pick on you. I can tell you for a fact though, that even in the sixties, when it took lots of effort to do material and labor based estimating, and then use that data for profitability targets the most successful companies were doing it, and they had to have large office staffs to accomplish it. It more than paid for itself. Today it's about a thousand times easier if you are motivated to pursue it.

I think our offshoot of this thread has run it's course.

From contributor La

Unless your estimator is unusually good on every possible scenario the use of fudge factors is a way of adjusting for unknowns. We break estimating down into time and materials. Materials are pretty straight forward. Time, not so much. Time can be refined with many job experiences but there are some processes that are subject to not very controllable times, things that get risky and sooner or later can go wrong. I classify Risk Factor as a cost. It is sometimes present and needs to be covered. That coverage is often a SWAG but still needs to be there in MHO. Hence the "fudge factor." Most often it is time but material can also have risks.

From contributor Pa

John

I'm familiar with the effects of jobs with high material and low labor.

Your pet word "winging it" is the pejorative for taking a calculated risk. But in all fairness you have an agenda.

You talk about companies in the 60s having a large office staff. What were the quantities they were bidding on? I actually agree that if you have big quantities you better sweat the minutiae. And you better know what the run times are going to be at a higher volume than a lower volume.

But if you are bidding one offs that is a different story and a large office staff will break you.

Why is this disingenuous?

From contributor Pa

I will add that the OP got a ton of good information, from some very good sources (including you), that fully answered his original question.

Since this "tangent" is not a tangent, I would say it is relevant and really has not run it's course.

From contributor Ca

I think the most useful part of this thread was the chart Prasad provided showing the implications of releasing work into the shop before it should be. It's a very convincing representation of how many extra resources are involved keeping balls in the air unnecessarily.

The OP's problem is that he doesn't have enough capacity to keep up with demand. A lot of times this capacity is unnecessarily tapped with projects that don't need to be in production yet. Everything on the shop floor takes space and management and these are the two bottlenecks that are usually hardest to ramp up.

Some of this can be managed with policy. Some of it can be improved with education but, as this thread points out, we have no tolerance for management by acronym.

From contributor Jo

Pat

I have no agenda here, save for the ideas that I espouse. I'm not trying to sell anything.

And it should be obvious that I'm not in favor of large office staffs. I was merely making the point that even when it was a hard thing to do (material and labor estimating) it was found to be very worth doing, and much of the data that came from it was used in scheduling and job costing to keep a project in check as it proceeds.

It's not that the estimate's always right .. it's clearly not. However, the estimate is absolutely right about one thing .. it will clearly show you where the profit point is. Use more materials or labor than what was priced, and you're cutting into profits and perhaps even your own money.

And IMO it's disingenuous to suggest that doing otherwise is a prudent way to run your expanding business which you are already losing control over.

lastly every job requires adjustments and has special needs. No surprise there. It's just are going to apply those adjustments via a 10% price increase or are you going to increase the install because it must be done in a compromising way, or increase your layup time because panels must be edged before facing, or whatever. In material and labor estimating methods these are easy things to adjust in an effort to get it right.

People will continue to do as they prefer. Which method would your banker or accountant feel comfortable with?

From contributor La

"Which method would your banker or accountant feel comfortable with? "

Never let a bean counter run a business!!!

From contributor Pa

John

In full disclosure (ingenousness) what were the volume of the jobs the large office staff bidding on? What were the quantities of units?

From contributor Pa

"Never let a bean counter run a business!!! "

Why not we have one running the country through the fed, look at how well that has turned out.

From contributor Ca

Pat!

It took you 58 posts to turn the OP's problem into Obama's fault???

You're slipping.

From contributor Jo

You guys are pretty cute ..

I'll answer the one real question Pat had ..

These are all architectural millwork companies. They do cabinets one day, paneling the next, and mouldings the next, etc. They did everything that came up, from a residential study to courthouses to 20' of matching baseboard and more. In short, whatever jobs they pursued they did material and labor pricing on. As you can imagine though they didn't get many 20' moulding jobs because they knew what it cost them and wouldn't charge less than a fair price.

It is the process (the standards and practices established in the company) they they choose and is not project size dependent. This way every project is handled the same way. And as you would expect, they use that data to dial in future estimates as well.

And while we can all share a good laugh at bankers' and accountants' expense I believe that we were to study the data carefully we would see that they have consistently made just a bit more money than us millworkers!

From contributor Pa

"they have consistently made just a bit more money than us millworkers!"

Good point where is that school on banking at again?

From contributor Al

Pat,

you don't need to go to school to be a bank, just sell to a GC, they automatically prepend "Bank of" to your company name. Unfortunately they confuse the relation ship and think that by doing that they have an unlimited line of credit with you with no real reason to pay you.

So back on topic of managing volume and cash flow, don't take extra work that pays too slow

A-

A-

From contributor Pa

Alan

You make a good point about banking, they all seem to subscribe to the same financial policy.

What is your take on the minutia thing, do you drive down to the smallest of details or do you use "big data" (how long did the entire reception desk take), on custom one offs?

From contributor Al

Pat,

Labor needs to be in groups or categories, minutia needs to roll up into shop measurable tasks so we aren't clocking in and out all day, the goal is to sell stuff a profit and know how long it takes to make money, any time tracking that adds to that cost without benefit is bean counting for bean counting, we need to count or measure and revisit to know how long our means and methods take us to perform.

One offs are more a all the detail adds up to this, I think it will take this long. Building 20 customs all the same is worth dialing in the processes.

I estimate a large amount of discrete labor tasks, tracking at that level is not practical. We have a lot of standard methods for a lot of dreams people have.

When I have to item price I will use budget labor operations that allow me to do it by the second, minute, tenth or 1/4 hour for each item or if its a regular customer I will create new labor tasks with times so they don't merge with other tasks.

I think on average the cost of a 1 vs 10-25 of something is 2.75 to 6x the 25 cost depending on materials and setups.

I see the difficulty you see in sending data to a scheduling software, we are hiring more staff an moving that direction so ask me in a few years. I am evaluating a lot of scheduling software options and then going to decide to buy or create my own. Right now we are finalizing our website which will have field work tickets and change orders and then I will move on to scheduling. I will be re doing my labor values and times based on events or groups that are discrete enough but that are easily to track. If we are building 3 boxes I don't need the minutia, maybe machining, assembly and installation.

If those 3 boxes get installed at night on the 34th floor of a high rise after hours in a difficult to access building well the cost of the cabinets relative to all the delivery and field mobilization costs and delivery costs may make those 3 cabinets 3-5k.

So catching those costs are as critical as the difference in a canted curved wall vs a straight wall. Take the canted curved all and insert a inset bent 3 form panel or bent signage nook and the degree of difficulty methods just doesn't work for me. Every time I throw 30k at a problem area in a bid, well it just isn't enough or it is too much, either way it doesn't have value that solves the problem.

Here are some of my operations, some are on hardware, some are on edging, some are on colors, some are on parts and some are assembling parts into products. If I choose a laminate face for a toe kick I get different labor than a veneer or lumber piece. My labor operations are parametric so they get counted, increase in quantity or go away just by the takeoff process then they are combined and I get a sample.

01 #100-S4S

02 102-Edge Glue 4 Wdth 1

03 102-Edge Glue 4 Wdth 2

04 102-Edge Glue 4 Wdth 3

05 102-Edge Glue 4 Wdth 4

06 104 Face Gl4thkns/2ply

07 104 Face Gl4thkns/3ply

08 104 Face Gl4thkns/4ply

09 104 Face Gl4thkns/5ply

10 104 Face Gl4thkns/6ply

100 Level /Install File Pad

100 Level /Install Tk

101 Install Base Cab Mod 091309

101 Install Die Wall

101 Install Mirror

101 Install Top Support Mod 091309

101 Install Wall Standard

102 Install Self Edge Field

102 Install Shower

102 Install Stone Tops

102 Install Sub Tops

102 Install Tops Rev 091309

102 Install Tops OLD DONT USE

103 Install Uppers Mod 091309

104 Install Hanging Strip

105 Setup Freestanding Fr

106 Make Custom Template

107 Field Measure

108 Cut Sink Hole

109 Install Scribe

10X Install Med Hardware

11 Training

110 Groove 6036 Drw Btm

111 Estimating

112 Install Metal Top Support

113 Drill 4 Cam Lock

114 Assmbl Drw Rl 2 Divid

115 Assemble Door Frame

116 Mitre Fold Straigt Rn

117 Mitre Fold Cross Fold

118 Clean Edging/File Edg

119 Prepare Sample

12 156 Thk Venneer Stock

120 Install Base / Chair

120 Install Box Beam

120 Install Cleats

120 Install Crown

121 Form Custom Radius

123 412-/Dado 4 Kv/Ins Kv

124 Presort Parts 4 Assmb

125 Groove 4 Slidng Clip

126 Sub-Contract Labor

127 Drill 4 Grommet

128 Install Gang Lock

129 Cut Part From Templat

13 200-Cut Panel To Size

13 200-Rip 8' Lengths

131 Welding Brackets

132 1 3/16" Panel Lay-Up

133 Shop Drawing Casework

134 Stock Billing (Ktx)

135 Project Actuals

136 Install Raw Plywood Backing

136 Install Reveal -Wall Paneling

136 Install Wall Paneling

136 Install Wall Paneling Celing

137 Install Door/Window F

138 Field Instl Door &Hdw

139 Forklift

14 204-Lminte Tops/Lg Pr

140 Cut Panel 2 Size Sche

141 Grind Knives

142 Set Up Moulder

143 Run Mouldings

144 Tail Off - Any Mach

144 Tail Off - Molder

145 Gang Rip -Setup

146 Feed Gang Or Straight

147 Hand Sand Slider

147 Sanding Finish Area

148 Masking Finish Area

149 Wrap Moulding Package

15 250-Wd/Pl.Edgbander L

15 250-Wd/Pl.Edgbander On Edge

15 250-Wd/Pl.Edgbander X

150 Build Pallets/ Crates

151 Load Pallets/ Crates

152 Clean and Prep Part

16 252-Egbnd/Pl Hndstk

17 254-Edge Band/Handclmp

17 254-Route and Install T-Mold RND

170 Install Tall Cab updated 092310

18 Bore-System(Face)

19 Bore-Construction-Face

20 Bore-Construction-Edge

20 Bore-Pocket

21 Assmbl Drwrbx/Mntslide

22 Bore For Hinge

23 Mount Base Plate

24 Drill For Pull

25 Drill 4 Front Adjuster

26 Adjust Fronts/Shop

27 Clamp Cabinet

28 Assemble Cabint/Manual

28 Assemble Cabint/Manual 1/4 HR

28 Assemble Shaped End

29 Inspect Cabinet/Clean

29 Inspect Single Part Product

30 Load/Unload Truck

31 Install Cabinet Hanger

32 Knotch 4 Hanger/Backs

33 Mount Slide To End

34 Hang Door

35 404-/Groove For Back/

36 Mount Pull

37 Rabbet For Scribe

38 Assemble Mount Lite Rl

39 Laminate Small Parts

40 Saftey Meetings

41 Assemble Solid Wd Tops

42 Install Drawer Front

43 Dado For Penaflex Rods

44 Saw Frme N Half Spltfr

45 Crosscut Lumber

46 Panel Lay-Up

47 Hand Snd Incl Blt/Vib)

48 Shaper(Includes Setup)

49 Travel

50 Machine/Shop Maint.

51 Shop Clean-Up

52 Project Management

53 General Office/

54 Photocopy Drawings

55 Shop Drawing

56 Install Cabinets

57 Cope Trim

58 Mitre Trim Field

58 Mitre Trim Shop

59 Rip At Angle

60 Setup Makor Line

61 Run Parts Makor Line

62 Feed Compo Line

63 Load And Run Parts Cnc

70 Office Prog Cnc Parts

71 Normal Maintinence Cnc

72 Special Repair Of Cnc

73 Shop Program Parts Cnc

74 Assemble Toe Kick

75 Assemble Countertops

76 Glue Jnt Sold Surf Mtl

77 Cut Angled Part

78 446/Route 4 Flush Pull

79 444a/Grve Dr 4 Sl Trck

80 444/Instl Slde Dr &Trc

81 Knotch 4 Hanger/ Ends

82 Wide Belt Sand

82 Wide Belt Sand Lumber

82 Wide Belt Sand/Prep

83 Route Letters

84 Install Pivot Hinge

85 Asmbl Door Fr/W Wndw F

86 Delivery

87 Insert Dowels

88 Recieving/Stock Hardwa

89 Pull Hardware For Job

90 Finishing

90 Finishing Assembled Unit

90 Finishing Assembled Unit GB

90 Finishing Base OPAQUE PARTS

90 Finishing OPAQUE PARTS

90 Finishing Prime Only

90 Finishing WD PARTS

92 Route Hole For Sink Ss

93 Seam Apron Or Bowls

94 Mount Flipper Door Sli

95 Form 4 Sec 1/2 Radius

96 Cut Radius Blank

98 Shop Supervision

99 Edge Detail W Router

Budget Field Labor

Budget Shop Labor

Cnc Program;

Cnc Program; 2600 Gable

Cnc Program; 2638 sh

Cnc Program; 2641 sh

Cnc Program; 2699 End

Cnc Program; 2699 Top

Cnc Program; Shaped End

Cnc Program; Small Panel

Cnc Program; SOFFIT PANEL

Cnc Program;3180 Pnl

Cnc Program;Arched Head

Cnc Program;Grooved Pnl

Cnc Program;Pog Pnl

CNC Round

CNC Slatwall

Epoxy Or Pur Glue Edge

Glue 4 Sided MF

Install Applied Back 1 per hour

Load And Run CNC

One Lot Subcontract Freig

open

open

Run 2 Long Edges Of Panel

Stack And Sort Part

XX Machine Door For Lock

XX #Custom Profile

XXX Custom CNC 1 Min per Q

XXX Custom Machine Stack Of Parts

XXX Install Casing Set

XXX Install CUSTOM 1 per hour

XXX Jig and Machine Custom Part Manual

XXX Mount Panel Clip

XXX Post Laminate End

XXX Stack And Sort Customer Material

Z Install 1S CASED OPENING ARCH

Z Install 1S CASED OPENING SQ

Z Install 2S CASED OPENING ARCH W JAMB

Z Install 2S CASED OPENING SQ W JAMB

Z Install Base / Chair

Z Install DOOR W JAMB AND HARDW

Z Install Receive and Sort Material

Z Install Spread Material To Locations

To increase volume we have a lot of things we need to know and track to succeed and its best to prepare before we get the work.

From contributor Jo

Quite a meaty post Alan!

I definitely concur that it's best to handle these things when pricing a project rather than later.

I also agree that there's a lot of uncertainty in just throwing money at a problem at bid time ..

From contributor Pa

"Quite a meaty post Alan!"

The whole list would be much longer.

To actually track this much minutiae on a one off would add a lot of cost to the bidding process.

From contributor Jo

Actually it's not hard, Pat. Our software has many more factors built into it that are selected automatically for you, depending on the type of item you are pricing. (i guess we've reached self promotion?)

The main thing is that YOU determine the level of detail that you want to operate at. Many of our clients only track maybe 10 categories with perhaps a total 15 or so total labor departments.

What you see in Alan's list is more processes than labor departments, which works well for him.

The key is whether Alan can run his business better from such detail. He feels that it's invaluable and he even wants to improve it some more. For yourself though, not so much ..

So the last time I used the accountant/banker perspective. This time if you were buying a business which would prefer? A company with a material and labor pricing process or the company where pricing doesn't directly relate to production?

From contributor Al

Pat,

We take off elements that have operation when we bid, I am bidding a little Maitre' D station,

It has a 1" leveling pad, a base cabinet with two doors, a "U" shaped column as the finish surround panels, a laminate top, a sub top for stone and a buy out stone transaction top

This is the minutia of our bid detail, maybe 20 minutes to take off, I am getting ready to price from this information

A

From contributor Al

John,

an estimate tells me how much is will cost, I think pricing relates to the market at some number more than cost.

All my labor operations are in departments and categories, departments have different labor rates, categories group discrete items together to make detail easier to manage.

My labor operations all have a setup curve, a labor curve and a point where the curve reaches maximum efficiency before the counting method changes. Each operation has a different basis, some are area, some are each some are length, some are circumference.

I can manage discrete information at whichever level I like, at the minute detail, at a general detail or a rolled up detail. I never start looking at a project at the minute level, my first number is sales $ per production hour, I then review installation as a % of sales, then I review material as a percentage of sales, then I look at the detail. I am going back to work.

A-

From contributor Jo

Sounds like you have a nice setup there Alan.

I wholeheartedly agree with your methods and your sales $ per hr metric. I take it from that, that you've standardized on a material markup structure for anything that passes thru the plant?

Ted Bolle used to say "cost is absolute, price is policy." I quite agree with that, as do you.

From contributor Er

I wonder if there is any metric more accurate for managing your business and your production than dollars produced per day, per man? This is how I've always schedule production from my seat in the office. From my foreman's location on the shop floor, he's going to use his experience to manage the day to day work flow based on his available resources: tools, man power, complexity of project, etc.

From the office, every job looks the same; its just dollars. Maybe it's grain matched veneer, or maybe it's a flush inset faceframe, maybe it's simple or maybe it's complex. Each style is going to require moving bodies into different departments to accommodate the needs of the job - this one has more boxes with less architectural parts so we shift labor to casework. This one has more columns and millwork and less boxes, so we shift a man towards woodwork. The end result is the same amount of dollar volume produced per day.

This method has worked flawlessly for years, I wonder if there's a point where size of company will make this method obsolete? Considering how much energy it would take to implement Prasad's system vs. my own, I can't possibly see the benefit.

Since I started this thread, I have spent considerable time pondering this while I've been driving from appointment to appointment. I have come to the conclusion that there are some aspects of what I do (things I've learned or have an aptitude for) that I cannot delegate to others. These are the things I have to focus on. Although there are many things I could do faster, better, and more efficiently than my employees, if those things are not items that can be classified as "can only be done by me", then I have to give them up. Already, I am seeing the potential in this. We are coming off the busiest quarter in our history with no end in sight, and are in the middle of work volume that exceeds even that, and yet everything is under control and every client is ecstatic with our quality and service. It's very exciting times right now.

Eric

From contributor Pa

"I wonder if there is any metric more accurate for managing your business and your production than dollars produced per day, per man?"

Yes there is.

From contributor Al

I look at dollars per production hour as a quick look to see if a price is in range or if it should meet a profit goal. We do not use dollars per hour or day for managing the business.

From contributor Jo

Eric

If you have a metric that has worked well in the past I suggest you keep using it. The factors that determine a good approximation of profit vary by how you account for overhead costs, how much you depend on material sales for profit, and what your own company limitations are.

I think your ideas about what to delegate are good and if I were you I would try to create a set of guidelines for each of those tasks that you decide to delegate. It might not seem urgent to do at first but I can guarantee that every process you don't define will not be to your satisfaction and will likely cost you money over time.

Good luck ..

oh, and one more thing .. just because you have the work it does NOT mean that you must expand. Any expansion you make to your business means that you have a bigger fire to feed each and every month. Tread carefully. Sometimes some subcontracting of tough items gives you more control and less headaches.

From contributor Pr

Eric said, "I wonder if there is any metric more accurate for managing your business and your production than dollars produced per day, per man? ".

This sounds quite similar to the business goal defined by Dr. Eli Goldratt. It cannot be easily achieved in the long run by ignoring improvement of other measures like on-time delivery, lead times and WIP (apart from product quality and reliability). In many high-variety, order-driven production systems, the problem starts with lead time quotation for new projects based on the existing workload and resource availability because various projects of different nature (and work requirement) are at different stages of progress, competing for shared resources for meeting the respective due dates. Quotation of smaller lead time can cause a lot of stress for the shop while quotation of long lead time carries the risk of losing sales opportunity itself. A problem with lead time quotation can ultimately affect employee morale, sales and throughput.

Improvement of WIP and lead times is a part of the popular Lean philosophy. Lead times and WIP must be improved to sustain and improve business. Increase in WIP leads to increase in lead times (as shown by Little's Law) with an adverse impact on both customer satisfaction and sales in order-driven production. It is not so easy to improve on-time delivery, WIP and lead times when multiple projects run simultaneously sharing common resources for getting completed by respective due dates. All these measures depend on the strategy of determining project start times which is also not easy to fix in general.

Eric said, "This method has worked flawlessly for years, I wonder if there's a point where size of company will make this method obsolete? Considering how much energy it would take to implement Prasad's system vs. my own, I can't possibly see the benefit.".

The apparent rational decisions on shop floor in real time based on experience and commonsense may not necessarily amount to the best possible production management. In many high-variety, order-driven systems, decision making based on workflow prediction can offer better results. An expert driver may use his driving skills to reduce time needed to go from point A to point B in a city during rush hours and feels that he is doing great. But, if a driver has a good view of the city road network along with projected traffic intensities on roads during rush time, he can select an optimal route to minimize his travel time. It is similar to prediction-based production management.

From contributor Pa

Prasad

Does your system depend primarily on Little's law? Is that why you are not too concerned with discrete assignment of times to particular jobs?

From contributor Pr

Pat,

Our scheduling system has absolutely nothing to do with Little's Law. It is based on finite capacity scheduling logic. I referred to the law in the previous post only because it shows the connection between WIP and lead time in general.

I am not concerned about scheduled start and finish times of operations because they are calculated from estimates and usually inaccurate on shop floor due to natural variation.

From contributor Pa

The reason I ask was because of your statement here:

"In my view, the most important elements of workflow prediction are the start and completion times of project"