Question

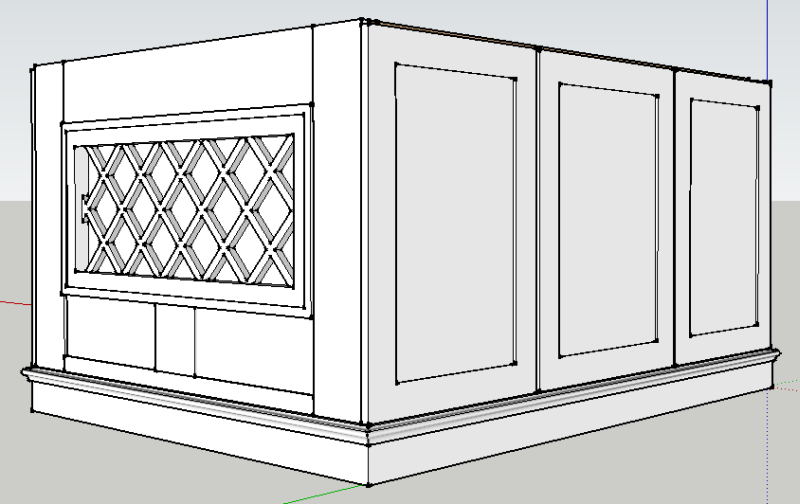

I have done a proposed design for a small island made from factory cabs and parts. I have a few questions I'll try to lay out here, after first showing some images of what is proposed. Here is a view of the finished island.

Here is another view of same. A range (slide in or drop-in, doesn't matter which) is flanked by 12w x 24d basecabs, and some panel stuff attaches.

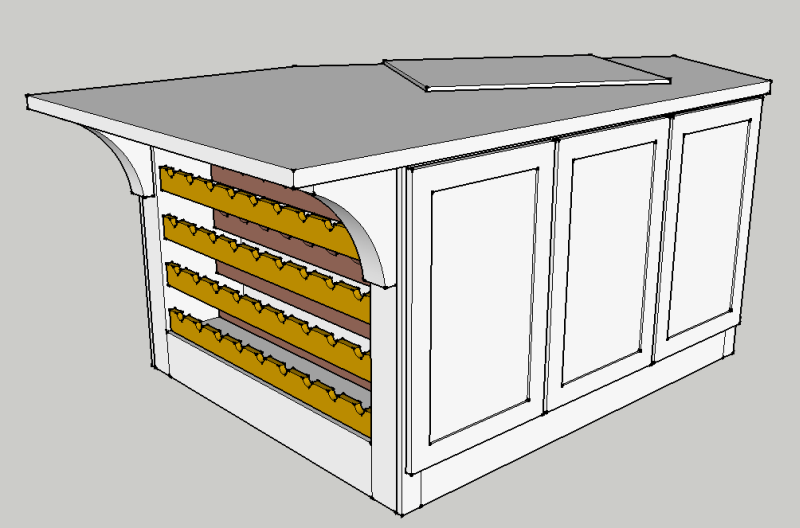

In the previous pic, you can see a wine storage cab under the counter overhang. I show one type of racking for bottles. Any good kind of racking for wine is ok here. You can see the three-panel side in that pic. In this pic, you can see the flank of the L basecab, its side decorated with a panel.

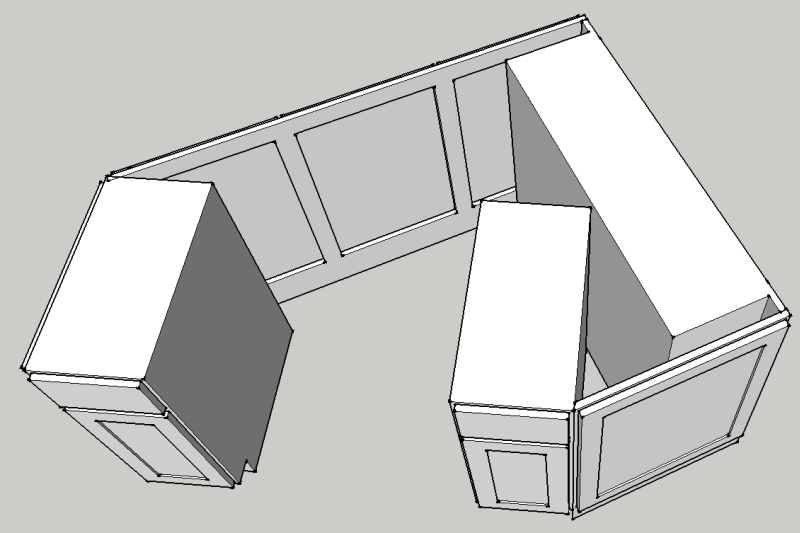

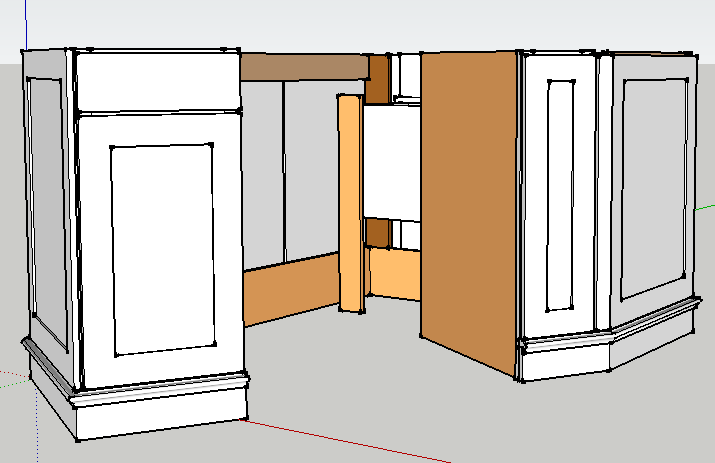

In this view, the range, corbels, and countertop are all removed, and you can clearly see how the three boxes, plus the panels mounted on stile-and-rail backing frames, make up the unit. Not shown are whatever heavier framing might get done with sawn lumber, to tie the whole shebang together and brace it and maintain spacing and alignment of all the component parts.

In this shot, one can see how a faceframed 12" deep cab, made with extended stiles, might get arranged in the design, with its stiles butting to the flanking panel frames. Again, the wine bottle racking is just sketched in. An X-thing might be just as good. It doesn't relate to the issues at hand here.

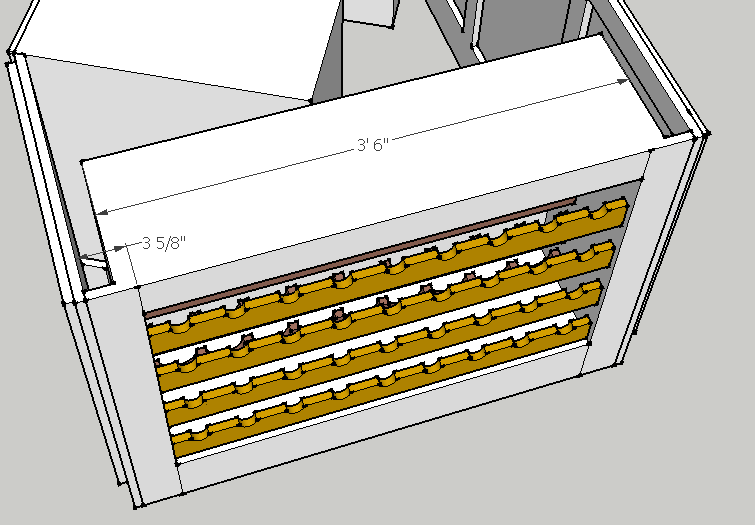

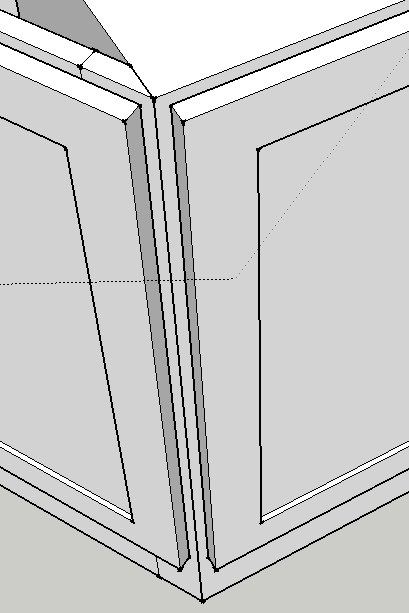

My biggest question for this relates to the joint between the 3-panel "back" and the back corner of the 12w basecab to the L of the range. Look at the pic here. A sharply-beveled stile meets the back corner. Itís really only ok if that cab can be purchased with a solid-wood, stile-and-rail panel for its left gable or side, and probably even better if that cab can have its side panel extended a little to the back. That way its edge could be beveled using the tracksaw with good blade, and we can angle the cut so the bevels match, here and for the back panel's stile. Dominoes or biscuits, and maybe we can do this.

Here is a shot of how the "frontside" panel springs away from the faceframe of the basecab to the R of the range. For this, a cab can be specified with extended stile R, and we can use the tracksaw to nicely bevel the stile, so as to best mate to the stile of the backer-frame for the panel.

How does this look to you? How would you approach this differently? Will it be possible to purchase a factory-made cabinet with the side panel we need, to enable the back-corner joint we have in mind?

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor D:

You might cut some angled blocks to fit the inside corners as needed .You can fasten the block to the outside part then screw the other from inside the cabinet to the block.

Iím not trying to dis the clientís dream because a cabinetmaker could build the island easily if that is what they want give it to them but it will cost more than stock cabinets. What do they want to end up with? A beautiful addition to the kitchen is probably what they want, not a conjured up sort of thing.

It is all different now - redesign. With this kitchen going into a vacation cabin, with eastern white pine as the trim elements everywhere, I decided to do this island with a facing of mostly 1x6 bevel-edge T&G boards. All "custom," but three frameless carcasses will be bought as part of the kitchen package, and integrated into this island. The range-side is shown here. Pulls on the drawers and spice pullout will be Epco EPC-DP42-BL3.

Here is the view from the opposite side.

The spice pullout will be the same Rev-A-Shelf unit you see used in this pic.

Here is a link to a slideshow showing how it might get put together on site.

For example, doing peninsula backs or backs and sides of my desired island, I found that one can use replacement doors in creative ways. At the nominal height of 30", one can get 13 different "standard" widths beginning at the narrowest (8-5/8") and up to the widest (23-5/8").

You end up kind of working backwards from the available sizes, but you can do some amazing stuff using these "stock" prefinished components. The really great part is that they are available in all those varieties of finish, the ones you can never do yourself, and get it right. The glazes, the rub-offs, distressing, highlighting, etc. Plus all the many stain colors. Shown without the corbels, here is an image of the desired island, using KraftMaid stock components.

Hereís a view from the opposite side.