Question

For those of you with a CNC, what is your design thickness of a tongue, or width of groove, and what is the actual measured number and variation of the piece that comes off the machine. For example: designed at 10.4mm actual 10.2-10.6mm etc. Also machine and bit type would be nice but not necessary. I have also found that the dimension of a groove at the top of the groove and bottom of the groove varies. What have you found?

Forum Responses

(CNC Forum)

From contributor S:

Accuracy and wood are diametrically opposed. I think it's good if you can machine wood/PBD/MDF to +/-.2mm (or more). Even IF it could be machined to perfect accuracy, it's going to expand and/or contract by that much in a few hours.

This goal is not as hard to achieve as it sounds with care and consistency in a few areas. Better is possible but really requires some work. This work may occasionally be desirable if you are doing solids joinery or something really special, but really hardly ever that I am aware of.

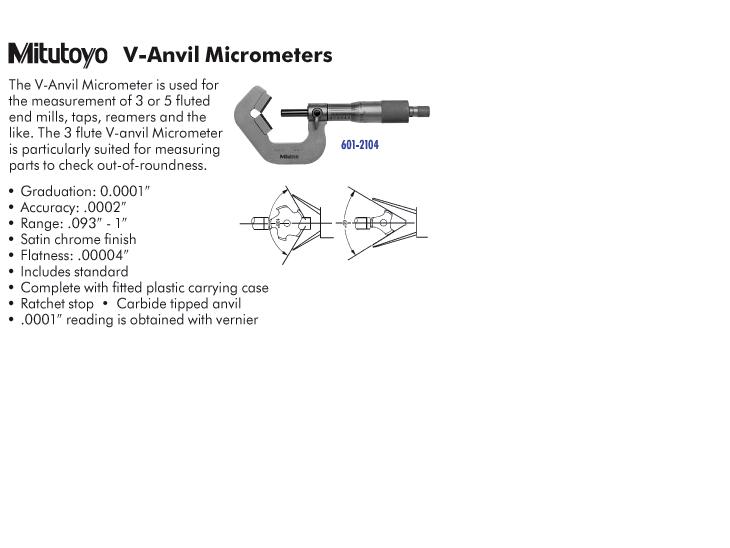

In the real world the biggest limiter to accuracy in actual performance is accurate tool measurement. There are issues like getting an accurate measured length of less than .001mm requires care and decent measuring equipment. Even .1mm requires attention to detail and reasonably decent measuring tools.

For example, how do you get the length of your tools? Can you really measure the same tool 3 times and get the same number? Dust alone can be a big barrier to accuracy. How do you get diameters, especially for 3 flute tools? If you are running a spoilboard is the set of your spoilboard cutter knives accurate to less than .01mm? (Likely not unless you are jointing after setting). All of these things can be done by woodworkers, and are done by machinists all the time. We just have to actually think about them and get down to basics with it.

The next biggest limiter is positioning of the workpiece. If you nest this it is less of a problem because the bit cuts the perimeter as well as all other operations. If you are working off pins it is a big deal. If you are on pods, you have additional consideration in that small movement can occur during machining if the vacuum doesnít hold firm to the pod and the gasket wiggles, for example, or the workpiece flexes between pod positions slightly. All of this, and the factor that others have mentioned, that wood (and most sheet stock as well as plastic) moves with temperature, humidity or both.

For that matter, cut a groove in melamine, a strip 8 feet long. I bet (if you measure accurately) you will find that at the entry point or very near it itís one thing and due to a small amount of bit deflection as the speed increases you get a slightly different reading at the middle of the cut.

Some people trust the sharpener to mark their tools, and this works pretty well, to a point. Mine came in for quite some time marked in thousandths. (way more accurate than the "cut a groove" method). Now I use a calibrating tool that measures the diameter directly.

I have never known anyone that gauges length by cutting a dado. Most use a touch pad or a measuring stand. If you are happy with the results though, and it works well for you, have at it. Maybe you can get to .1mm that way, but I can't seem to get consistent results with that method. I attribute it mostly due to a variation on pull on the spoilboard depending on how thick it is and how well covered it is, and also the fact that the accuracy of the "cut a groove" method depends on the accuracy to which you have already gauged your flycutter.

You are absolutely right in saying that tool size is only a starting point. If you start with accurate tool sizes diagnoses of other issues is possible. If you are shotgunning or guessing at tool size then all else is futile.