Can Machinery Make Dovetails that Look Hand-Cut?

The simple answer is "no," but here is some discussion. March 28, 2010

Question

I've been using the Akeda and Leigh dovetail jigs off and on for years now. They're great and I really value the ability to customize the look of the joint spacings. However, they're too slow and far too prone to user error for a production environment.

I'm looking to upgrade to a dedicated machine, but I'm having trouble finding something that will allow me to make my favorite staggered patterns and retain the handcut look I got from the jigs. Part of the problem is that the bigger machines look like they're going to use 1/2" bits, which is too big to create the narrow spacings you can create with a 1/4" bit.

Perhaps my best bet is to take a Powermatic or Dodds machine and pull the spacing template off and have a new one machined for my own style and spacing of dovetails. Is there something out there that will work for me? Do I need to resort to modifying existing machinery? Am I stuck with a router and jig?

Forum Responses

(Furniture Making Forum)

From contributor K:

To the best of my knowledge, no production dovetailer can do what you are asking. Most if not all of them run with multiple spindles that are machined and assemble to perfect spacing and can't be changed. Maybe you could drop out some of the bits but you will never get the look you are asking for.

From contributor D:

Dovetail jigs do not make handcut looking dovetails either.

From the original questioner:

There are plenty of smaller, single spindle, manually operated dovetail machines. I'm just wondering if anyone has used this type of machine to create the finer looking results you can achieve with the router jigs. Just to be a bit more specific, here are a few of the machines I'm talking about: Dodds SE-1, Laguna Dovetail Platinum, and Powermatic DT65. I like them because they have pneumatic clamping and the motor rides on a fixed, stable carriage unlike a handheld router perched on top of a jig. Anyone have any experience making these things do finer work?

From contributor J:

While not anything like hand cut dovetails I'd never give up my dodds se1, I usually only use the traditional half blind set up on it , but the spacer bar does have different spacings on it for a few other options. I'd touch base with them they're really nice to work with.

From contributor P:

I also have a Dodds SE-1, and it's a fantastic machine - very simple to operate, totally reliable, and even has good dust collection! It comes with 4 possible spacings for 1/2" dovetails, but doesn't replicate the look of a Leigh jig or handcut. However, don't assume that your clients know or care what kind of dovetail they are getting, and it's a bad idea to give clients an expensive feature that they don't value.

From contributor E:

What you are looking to do with a dovetail machine can't be done with a Dodds SE-1 or the Powermatic. Matter of fact, it can't even be done with the Omec 750CN. I had a Dodds SE-1 before buying the Omec 750CN. In order to do it on the Dodds you would not only have to make a custom template for the follower to reference off, you would also have to make a custom set of fingers for the vertical piece being machined to support it. It could in theory be done, but really isn't practical. You could cut an awful lot of dovetails with a router and jig before you got that done. The Omec 750CN can give you variable spacing but all the pins and tails will be equally spaced. You can put in as many or as few as you want, but they will be equally divided. The machine that is capable of doing it is an Omec F-11. That's a $50k machine and it would take an operator that would be willing to do the programming in order to pull it off.

What I have been doing and offering my customers is on their tall drawer boxes, 10" and larger is to run just five dovetails rather than the ten that you would normally see with a fixed spacing machine. That's about as custom as you're going to get with that machine. The advantage is that it can run any height drawer box and always finish with a balanced pin and tail.

From the original questioner:

Thanks for all the suggestions. I've checked out the YouTube videos, but I'm still not sold on the CNC dovetail machines. Guess the router jigs are going to be my tool for now. We'll see. Thanks again guys.

From contributor E:

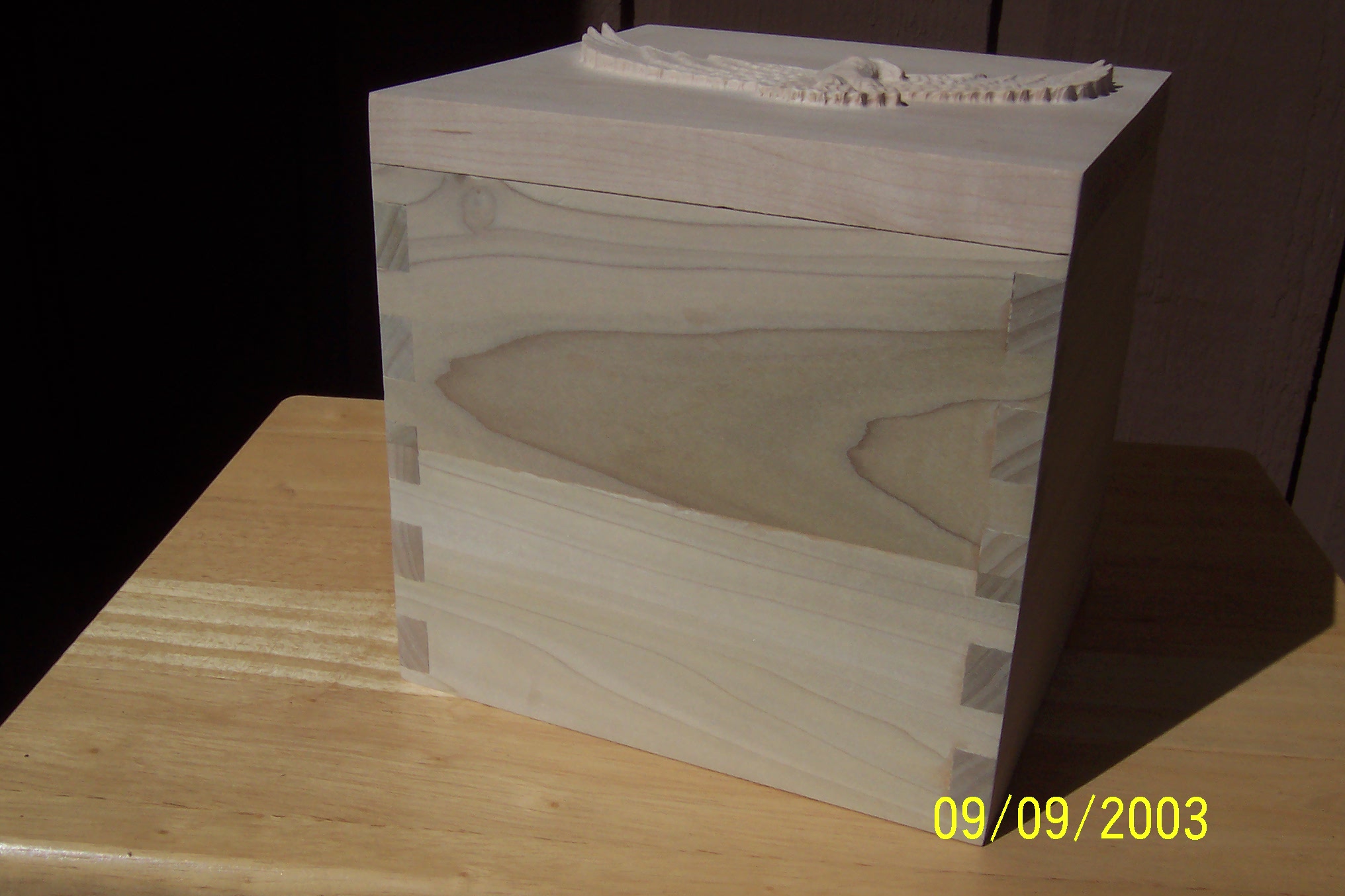

Here is the picture of the 10" drawer box I mentioned in my earlier post. As you can see, the Omec 750CN is capable of running various size dovetails, but they will always be balanced. The shops that I build drawer boxes for have come to like the looks of the wider pins and tails in their tall boxes rather than the busyness of the dovetails on the 1" centers.

Click here for higher quality, full size image

From contributor T:

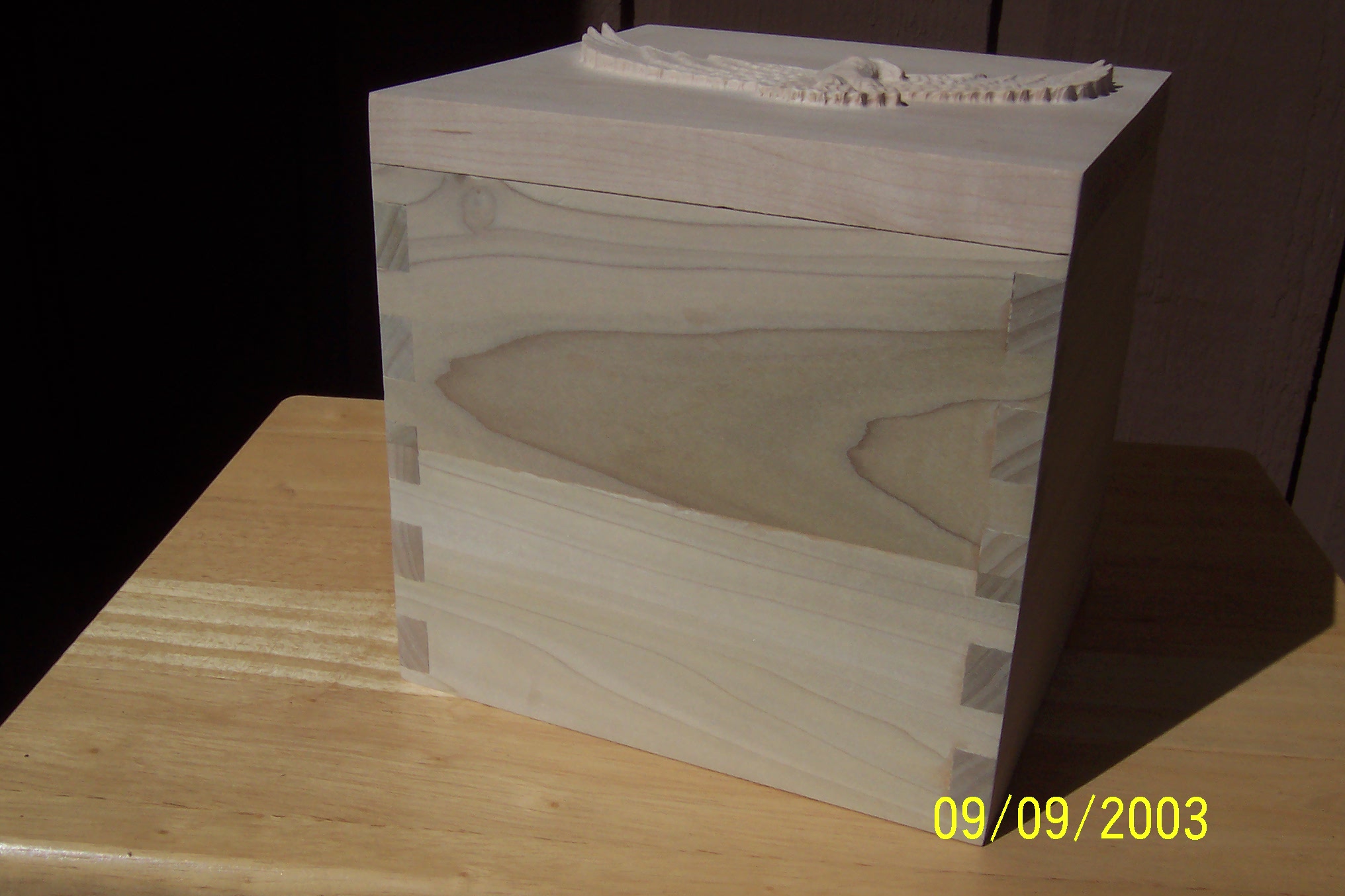

I have been playing with dove tails on my CNC machine this winter and I believe you can do any spacing.

Click here for higher quality, full size image