Question

We want to produce French Provencal style armoires and furniture pieces like the one pictured. We hand carved this piece in-house and used traditional machines (shapers, etc.) for the joinery. We are now moving to CNC production and have ordered a 4 axis CNC router (std 3 axis with a side mounted rotary lathe axis).

Excluding the carving ornament, what CAD/CAM software would do this the most easily? We want parametrics so we can resize cabinets. We want ease of doing the complex curves of the doors, crown, skirts, feet. We want true 4 axis control so that we can produce the corner posts/feet in the round. We'd like to be able to easily import an STL 3d scan of our hand carving (we recently bought a NextEngine scanner).

We have a tight budget and want to spend the least money and time to get the job done.

We've focused our options on three packages:

1. MasterCam for everything

2. AlphaCam for everything

3. SolidWorks for the main CAD design, Rhino3D for the special freeform shapes like the scrolled feet, Visualmill/RhinoCam for the CAM.

Which do you recommend? Other options?

Forum Responses

(CAD Forum)

From contributor R:

I hate to say it, but the NextEngine scanner may be the weak link in your plans. I think that any of the other programs listed could be used, and sometimes it is just a matter of what you learn on, and get comfortable with. That said, Rhino is cheaper than any of the other programs mentioned, and just as powerful and useful in its own way. If you can learn to model with it, you will eliminate the hassle of scanning and trying to use STL files, which can be frustrating. Keep in mind that whatever programs or techniques you use, you will still need to clean up all the carvings by hand to achieve the look you want.

Solidworks with something else can be a powerful system, however you must pay two maintenance fees, learn two interfaces, and inevitably you will have some degree of disconnect between the two. Manufacturing systems like the ones I mentioned will allow for all of these things, including drafting and parametric design, but most importantly for wood products will allow you to have association between your model and the machining. This means when you make a change to your model you don't always have to re-create your machining files. Much of the machining can also be set up automatically. When you export from Solidworks to a system like Mastercam/Alphacam you have essentially a dumb file that has no logic, so Mastercam/Alphacam has to do a feature recognition to guess how things need to be machined based on some criteria that you give it. When you work in a singular system, the guessing is diminished substantially and a link exists between model and machine.

No matter which one of these systems you might choose, you will find that they are not easy to learn, no matter what anyone tells you. Moreover, what you wish to accomplish with importing .STL files is very taxing on any modeling program. Also, it should be noted that machining .STL files can provide many challenges. Be careful in your assumptions about the capabilities of all of these systems. Just because we can produce airplanes with these systems does not mean it's easy to produce furniture. Everything you are asking for can be done, but it will not be easy or cheap. I have much experience with this type of process and have learned many hard lessons. The cost of the software is easily eclipsed by the investment in time that you must make to truly harness their power.

Similar is different. CAD yes, CNC yes, but not on that level. In some ways better, in some ways worse. You can 3D scan a hand carved cabinet and then import the point cloud, use a product such as Paraform to create NURB faces, slice up/cut up that for CNC carving. In effect, reproducing the original. The machine time would be very high. Again, more expensive than having a carver just do it. These are the realities.

Appreciate the input! Anybody out there actually producing solid wood furniture with the complexity of this piece?

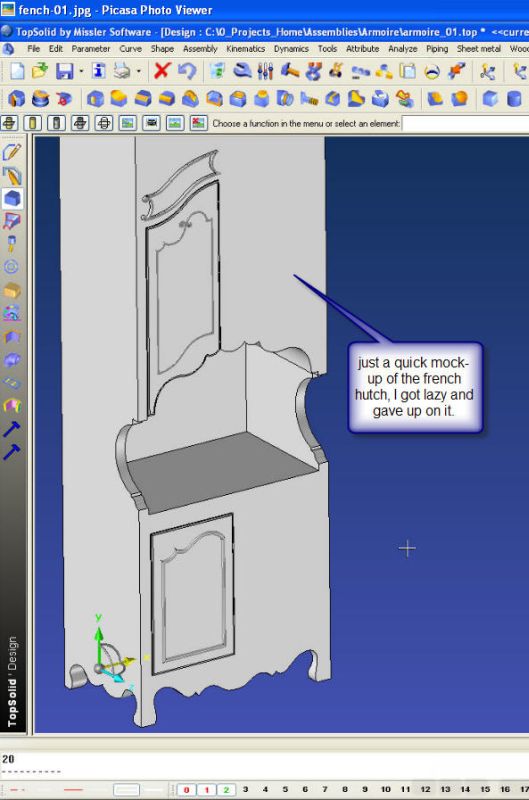

Solidworks jockeys! How easy would it be to CAD up the basic piece of furniture above with the complex curved door rails and the curved skirts, etc., but minus the actual carving ornament (flowers and leaves)? How long do you estimate it would take you to do it?

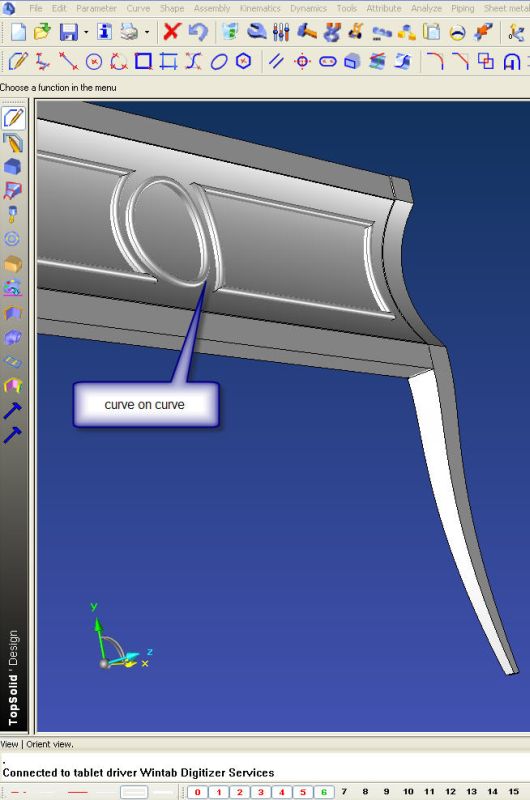

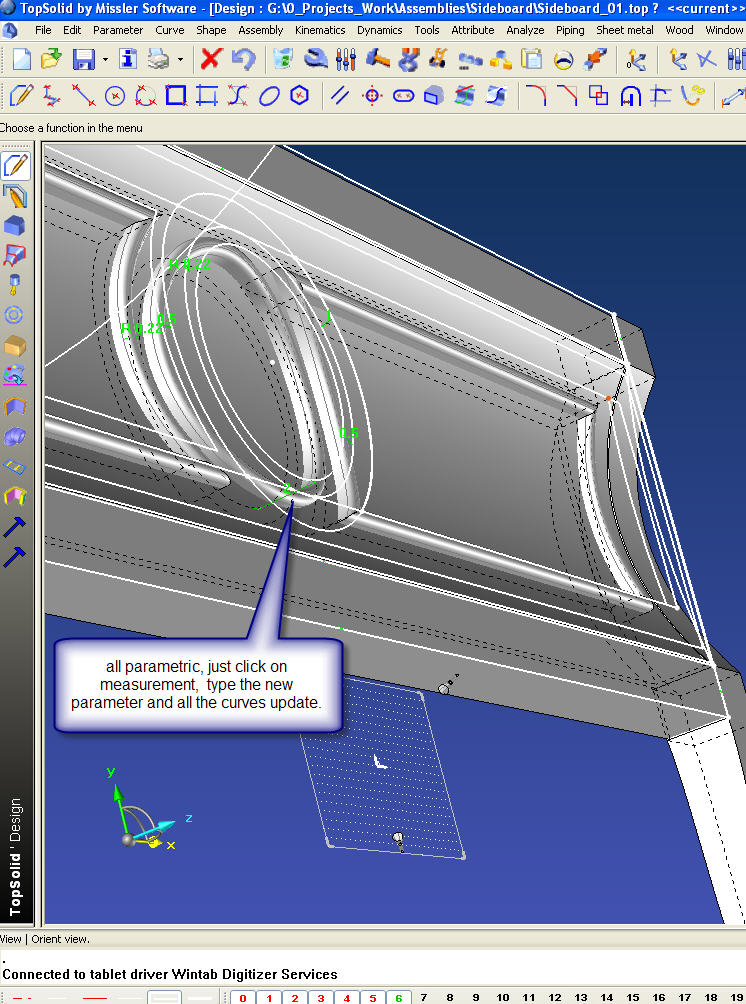

TopSolid users! Minus the ornament (leaves and flowers), but including the curved parts like door rails, how long would it take to CAD this using TopSolid?

I like what I saw in the online brochure for TopSolid Wood. Seems like the libraries would be a great way to save time by using previous parts to design new things

The reason I went with TS is because it is the only true 3D engineering modeling software that also has a woodworking overlay built into the system. When I say engineering software package, I mean it has built in functionality for sheet metal stamping, mold making, tubing and routing, and of course woodworking, as a furniture designer I need all of those features.

If it is that important to create the carvings digitally, and you have a skilled carver, you might want to look into ZBrush. With its latest release you can export STL files and have an extreme amount of control on polygon count and file size.

Comment from contributor A:

The packages that have been discussed, so far, are quite good. However, I found the learning curve quite steep. I finally ended up using a CAD/CAM package from Vectric called Aspire. Not only was it less expensive, it is almost intuitive to use. Also, there is a company called VectorArt3D that has most of the artwork ready for production at a very reasonable cost. Both companies have websites and free demos. I went through three very expensive CAD/CAM packages before I found this software. I could have literally saved $1,000ís while making $1,000ís if I had found these two companies first.