Clamping for a Curved Edge

Ideas for clamping curved solid banding onto a curved tabletop edge. October 28, 2008

Question

I'm planning to build a smallish veneered table top which will be horseshoe-shaped. I own neither an edgebander nor those fancy cam-type edge clamps, and I want to use fairly heavy (at least 1/8") banding material. I'm looking for thoughts on how one might clamp that edging onto such a shape (180 degree, 17" radius curve, plus straight sides) for glueup.

One idea that has occurred to me includes a ratchet strap, possibly with wedges tapped in to tighten it in places, but I'm doubtful this would give me sufficient or even pressure all the way around.

Another idea is to trap a length of small-diameter fire hose between the tabletop and some sort of disposable restraint built from scrap, and use air pressure to do the clamping.I have yet to try either of these ideas. Before I proceed, I thought I'd bounce them around here. Thoughts?

Forum Responses

(Furniture Making Forum)

From contributor A:

Your fire hose idea gave me another idea that I probably wouldn't have thought of if I was doing the job myself (I would have used band clamps). Anyway, my dad had a garage business. When changing tires, he had an inflatable strap that went around the tire to squeeze it when trying to set the bead. You would put the strap around the tire, tighten it, and inflate it. It would then squeeze the tire so the beads got closer to the rim. This should be a great flexible clamp for special applications in our business too. They're a little expensive, but aren't all clamps?

From contributor M:

I would take a scrap sheet of protection board or particleboard and make a mirror cutout of your table shape less 1/8" and use this to clamp with pipe clamps.

From contributor H:

Go buy the clamps you need. It's a one time investment in yourself and your shop. They have a very long shelf life and can be used over and over again.

From contributor K:

Attach the work piece to the table or work board. Bend the edge banding around the piece. Add a few extra layers of 1/8" (not glued) to the outside of the edge banding to distribute the load. Fasten blocks to the table around this setup, spaced where you would like to put clamps, but leaving some space between the stack of 1/8 material and these blocks. Hammer opposing wedges into the space to apply clamping pressure. Make sure to start in the center and work outwards.

From the original questioner:

Thanks for all the ideas. The tire clamp looks neat, but isn't long enough for my application. I've used the mirror cutout/pipe clamp scheme on less extreme curves, but I'm not sure it would go well on a full 180-degree turn. Someday it might make sense to invest in the edge clamps, but for the moment I can't justify such an investment. This sort of situation is fairly rare for me, and the clamps I'm aware of (Harbor Freight version excepted) are very expensive. On the other hand, this sort of wondering and experimenting isn't cheap either... The block-and-wedge idea sounds workable, too.

From contributor T:

Sounds like you might own a ratchet/strap/wed clamp already. If not, they're about $4-5. Use that and the flexible cauls contributor M mentioned and that will do the curved segment. Use a wide board caul for the straight and an opposing board bar clamped on center and one on each end.

From the original questioner:

That hybrid approach may make the most sense. The ratchet strap can take care of the curve, and some straight cauls and bar clamps can handle the straightaways. Now I just have to figure out how to get the ratchet strap in place and tightened with only two hands.

From contributor T:

Maybe you could use the handyman's secret weapon to restrain the edge banding and cauls, thus freeing up your two hands to slip the strap around and tighten...

From contributor S:

Go buy an inner tube and cut it into strips and just tie them. My dad did that for years way back when. There are very few shapes that it won't work for. You can make them whatever length you need.

From contributor Z:

I would wrap it in a few layers of plastic shrink wrap, like warehouses use. Put a bar clamp over the seam.

From contributor L:

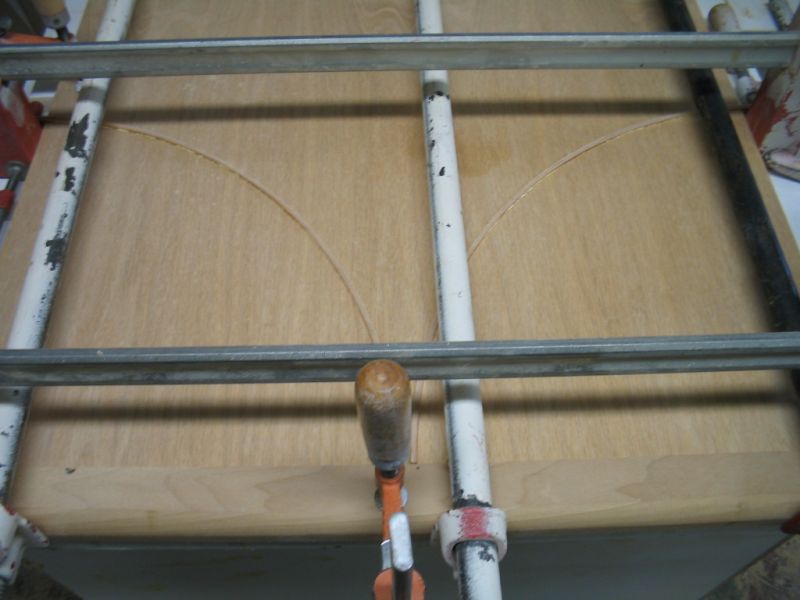

The image is radiused corbels routed with a template and a 1/8" bit to match the 1/8" oak banding.

Click here for higher quality, full size image