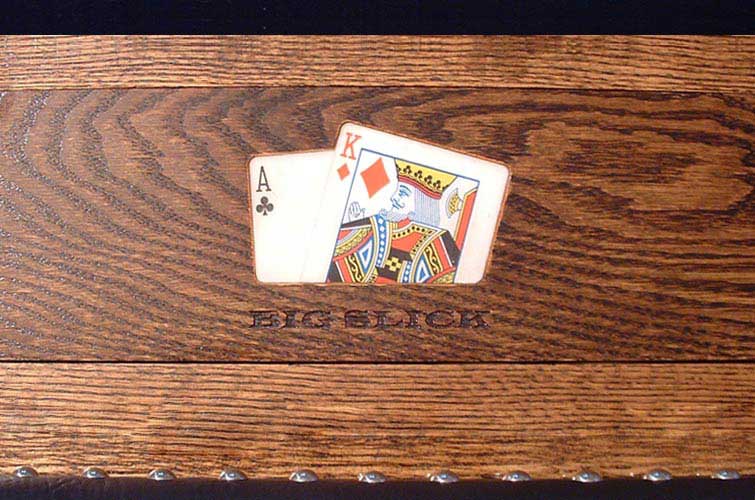

Clear Epoxy Over an Inlay

Tips on applying a thin but tough clear finish over a delicate inlay detail. March 9, 2006

Question

I am currently constructing poker tables with cards inlayed as shown in the photo below. I am curious as to the best method/materials for inlaying items in hardwood. Last time I simply routered out the area for the two cards, glued them down and then covered them with a plastic resin.

This technique seemed fine at first but the resin took weeks to fully dry and cure to a full hardened state. And once it was cured it is easily scratched. I was curious if there is a better way to do this. What else can I use besides resin? I have seen restaurant tables and bars that have inlays under a thick resin-type surface and they seem to be much more scratch resistant. Where can I get a similar resin or other product?

Click here for full size image

Forum Responses

(Finishing Forum)

From contributor M:

There are lots of resins out there. Was it a "two component resin" like an Epoxy resin with a hardner? That is commonly used for that type of work.

From the original questioner:

Yes, it was a two-part resin but it may not have been a great product as I bought it at a local crafts/hobby store. I want the cards to look like they are as close to the top of the wood surface as possible. If I cut the inlay shallow enough - would putting extra clear coat

polyurethane on the cards be another way to seal them in? The wood is getting a clear coat anyway.

From contributor M:

You want a water clear high solids coating that is durable and chemical resistant. The 2 pack Polyester or

Polyurethanes would be another option, both of these coatings are high solids, durable, and chemical resistant coatings have these excellent features.

From contributor R:

To the original questioner: In your first post, you referred to "inlays under a thick resin-type surface and they seem to be much more scratch resistant". Now you're saying "I want the cards to look like they are as close to the top of the wood surface as possible". These are two different scenarios.

But first, a comment on your previous problem of "weeks to fully dry and cure". Something was wrong about that product/application. My guess is the mix. Some two-part epoxy type finishes can be extremely fussy about the ratio. Too much resin or too much hardner can cause what you described, and worse - it may never set. Be sure to be exact in your ratios.

The advantage of a thicker self-leveling bar top finish is exactly that - it is self leveling. That will take care of an inlay that is slightly proud, or slightly recessed. In your case, I think it would be almost impossible to get those cards perfectly flush with the top.

Therefore: The "thin" solution would use poly, or CV, or just about any clear hard coating (water based would tend to be the most clear and non-yellowing). But I think you would have to treat the project similar to grain filling with finish alone - apply coating (just to the card area) and sand back (without scratching the cards), then repeat as many times as necessary to get the cards any reveals around them (pretty accurate routing required) flush with the table top, then clear the whole works. Even at that I suspect it will be very difficult to end up with a perfectly flat top - no depression where the cards are.

Also, you may want to consider using plastic cards to prevent any moisture issues (like the cards delaminating or swelling). That assumes of course that neither your glue nor finish will "melt" the plastic card. So my recommendation would be the bar top finish. Perhaps you could simply apply it to a minimum thickness.

From contributor M:

I agree with Contributor R about the measuring being exact to get a faster uniform cure time. I have done poured out coating over a thin veneer of a faux mother of pearl, and the pour out coating buried the veneer in one pouring. These poured out coatings take some planning and must be thought out.

From the original questioner:

I was posing two different questions as far as which finish method would work the best. In either method I would like the cards to be near the surface and the top coat (whatever it is) to be scratch resistant. I like the resin/bar top finish idea best, but the thinner the layer the less self-leveling effect I seem to get. Does this make sense?

From contributor R:

I think that would be a true statement. However, a major advantage of these two-part self leveling coatings is minimal shrinkage as they cure. With a traditional finish, as the coating cures or flashes, surface tension will "pull" it down into any depressions or irregularities. The two-parts won't - or at least not to the same degree. Or to put it another way, the wet mil thickness of the two-part is much closer (if not the same) to its dry mil thickness than other coatings (like varnish or lacquer). This is a conundrum you are going to have to come to grips with: thinner coat equals less self leveling.

From contributor M:

Below is a piece of "faux" mother of pearl veneer that I buried under a poured on finish. There are no solvents in poured on coatings, "no solvents, and no shrinkage". If there is any shrinkage, I don't think it could be measured.

Click here for full size image

From the original questioner:

I decided to go with a fairly shallow cutout and filled it with the bartop resin. I really like the way it turned out. The resin set up nicely. We use a laser engraving/cutting machine to do the text. It can cut acrylic and thin wood or do engraving in about anything.