Communication Between Cabinet Shops About Outsourced Work

A busy cabinetmaker who needs to send work to another shop for cutting on CNC equipment wishes the other shop would meet him halfway on the transfer of information. A debate ensues. January 31, 2012

Question

If an unknown general contractor calls up a cabinet shop owner to bid on a project (that the contractor doesn't even have yet himself and may not ever get) the cabinetmaker will willingly jump in his truck, drive across town to look at a potential jobsite, agree to take a set of plans, spend half a day carefully looking for all of the snakes, and then cheerfully submit a bid - all for a one time (and maybe never going to happen again) deal.

If another cabinetmaker, however, attempts to purchase work from that same cabinet shop owner the cabinetmaker is somehow required to do all of the leg work and all the cutlists to make it road-ready to drop right into the CNC machine or all bets are off. Itís can't happen - impossible.

If it is for a GC the cabinet shop owner can move mountains. If it is for another cabinet shop then it has to have all the management in place, DXF files rendered, or it simply cannot get into production. Can anybody explain this dynamic?

Forum Responses

(Business and Management Forum)

From contributor F:

You already know the answer. The real question should be "why am I outsourcing to my competition and sending my potential profits to him"?

From contributor W:

I am kind of slow with this so work with me. I have a CNC and you want me to cut your parts. You do not want to provide file work for cutting you want me to do? Isn't this a bit like guessing which sink will be used by others and cutting the hole anyway?

From contributor D:

I'd be more than happy to treat you like the contractor as long as you agree to pay the contractors price. Price is related to time. The less time I need to put in to your project, the less it will cost you.

From contributor C:

If I was concerned about saving money I would cut and drill the parts myself. I have six kitchens to build and four more to sell. My time is better spent closing sales. His time is better spent being more cooperative (being willing to accept data in whatever format it needs to start). Put another way: If a general contractor was only able to communicate with limited information he could somehow figure out a way to get the data into the CNC machinery.

From contributor V:

I agree with Contributor D. The problem I see most of the time is that other shops donít want to pay the same price as the contractor. I price our jobs quite simply: Time plus materials plus profit equals our price.

Our price is our price to anyone whether contractor, home owner, or another shop. If a contractor says why donít I get a better price than the home owner my response is that you get the best price possible. That solves the argument for me. The only time I can give a better price is when I have a contract guaranteeing more work.

From contributor C:

I doubt very much the component supplier would ask the lady who buys a kitchen from him to provide a DXF file. If he can figure it out for her he can figure it out for another cabinet shop owner. The bottleneck in this market is probably sales. I suspect there's more excess capacity at the programmerís desk these days.

From contributor R:

It sounds to me as though you need a project manager or are willing to pay the CNC shop for that service. I cut for four shops in my area. I always inform them that the final result is directly attributed to the amount of time and information they are willing to spend in front of a computer with either myself or my CAD guy.

From contributor C:

We build our cabinets using parametric indexing. The pattern for drawer holes is always the same. A group of four indexed 37 mm from whatever the closest structural element is. If the closest structural element is a 19mm floor then the drawer slide holes would center 56mm from the bottom of the cabinets (19mm + 37mm = 56mm). If the closet element is a faceframe rail then the drawer slide would center 37mm above this faceframe rail. All of these relative locations can be expressed as a distance from bottom of cabinet. We can easily produce an excel spreadsheet to generate these values.

The problem I have is that nasty customer that wants to use different thickness of countertop and different heights to top of countertop. They even have the audacity sometimes to want special heights for various drawer fronts. All of this requires a little bit of spreadsheet work so I tough it out and generate the numbers. My cabinet component vendor would like me to instead generate a DXF file with all the holes accurately placed. We need one DXF file for the system holes and one for the construction dowel holes.

I could generate these drawings for him or I could generate drawings for three new kitchens today. I suppose I could also just hire another project manager. It probably wouldn't take more than another $20K in sales each month to feed him except the extra sales will probably also require some more staff to produce the work. This might be a good idea. It might actually be easier to accomplish than trying to buy parts from another cabinet shop.

From contributor V:

I have actually been on the receiving end of a CNC shop telling me I had to supply them with the CAD file. They didnít want to do the work necessary to take my floor plans drawings and other info just like they would from the contractor and yet wanted to charge me the same price as they did the contractor so I can understand where the OP is coming from. I think itís just a frame of mind.

From contributor D:

The potential supplier of the service I think does himself a disservice by insisting on dxf or whatever on a number of fronts. The first relates to layout and efficiency. If I control the layout, I control my efficiency, not the client. Second, if the client has the ability to generate dxf file he has the ability to shop the work. If I have taken the time to set up a specific clientís parameters, I will always have the advantage in the future. Third, and this may or may not work depending on many factors, there is the ability to charge a set up fee, either one time or per job.

What I don't understand is philosophy that tells your customer what he wants. The client does not need to deal with you. Part of good business operation is to create a relationship where the client wants to deal with you. If as mentioned in a previous post, the client wants a hole pattern different than what you typically use, so what they're the customer. If you don't want to deal with them then good, because I do. Yes, there should be a price difference between fellow trades and consumers. If not, you eliminate one market or the other. At the end of the day, while I spend my day cutting panels and such for my clients, when asked what I do for a living, I say that I help my clientsí make more money.

From contributor K:

Just as a skilled cabinetmaker can take a magazine photo and a rough floor plan and turn it into a fine, working kitchen, the CNC guy should be able to take some raw data from the cabinetmaker and convert it so he can make parts. The cabinetmaker has a skill set that converts and adds value to the project. The CNC guy should do the same, no?

This is where I see CNC people fall down all the time - they can't or won't take that kitchen floor plan or even a detailed cutlist, and turn it into a stack of parts. They expect the cabinetmaker to provide everything in a package that they can just load into the machine. If the cabinetmaker has to do all that additional work, then he will acquire CNC ability sooner rather than later, and the parts maker will lose.

I don't do cabinets or CNC work, but I have a customer that sends me work ready to go to my shop for fabrication. Others can take days or weeks of back and forth, drawings, changes, samples, etc. Not only does the shop ready customer get a price without all the upfront costs, he gets our best price since he has made it so easy to do his work.

From contributor A:

I view outsourcing as make these parts for me to my specifications (doors, drawers, trim, cabinet parts). I view subcontracting as here is a project I have you build it per the plans. In one case you have engineered the work and now have all the information but don't have the shop time to produce it. In the other case you were awarded a job and want someone else to do all the work. Outsourcing has a lower cost than subcontracting.

From contributor M:

There is one dynamic I don't see mentioned here. The fact that the contractor doesn't really care about what techniques I use to build the cabinets, all he wants is a finished product. The cabinet shop customer has to be concerned with the method of construction as he will be getting parts that he will have to put together. These parts can be configured in many different ways for different techniques. If you want me to make a set of cabinet parts, based on my construction techniques, I will sell it to you at a reduced cost and less than I would sell completed cabinets to the contractor. You will then be responsible for assembly and install, without my help. If you then need my help to explain all my techniques to you and train you to assemble and install by method then that's going to cost you. Or, look at it this way, if your techniques differ from mine, then I have to reprogram my parts list to match your construction, the re-design time is going to cost you. That makes me responsible for the parts if they don't fit. That too is going to cost you as part of overhead.

That is why I (we CNC shops) require (ask) that other cabinet shops provide us with shop drawings/dxf files to machine parts. We have to make sure we are supplying you with what you need. Now, if you are asking for completed cabinets, that is another issue. It should not matter what the construction techniques are as long as the finish product is as ordered. In order to get those at a "wholesale" cost, you (the cabinet shop) will need to supply shop drawings with all dimensions. You would then be responsible for the finished cabinet sizes but not responsible for whether I choose to use blind dado or butt joint construction.

From contributor I:

I cut parts for others also. Itís pretty simple. I have a cost to cut a sheet of material. If you need programming itís another cost. Your welcome to my libraries, or I will develop your very own set of libraries, at a cost per hour. Basically, programming is programming, cutting is cutting. Cutting charges donít include checking your drawings, design consultations, providing you with your door and drawer sizes, etc. I have fired several of my cutting customers because all they did was eat up my time and cost me money. If I charge you $35 to cut a sheet, I canít talk about it with you for two hours. I also canít afford to spend two hours programming ten sheets for you. It has to beneficial on both sides.

I cut for a guy who does closets. I charged him around $500 to design and program all the parts he was going to need. Now he sends me a spread sheet with the parts and pays by the sheet. Occasionally he needs a couple more parts added to his library, he then pays a one time programming fee. Pretty simple and works out for both of us. I learned the hard way after spending untold hours developing libraries for guys at no charge, then cutting two or three projects for them, never to be seen again. That 150k machine sitting out there canít read your mind.

From contributor U:

I agree with Contributor I. I cut for two shops, both require that I spend time taking their rough drawings and inputting cabinet data to generate the necessary code. I charge them for this time, and am happy to do it. When I was outsourcing my cabinet parts to another shop prior to having my own CNC, I generated my own G-code for their router. All they had to do was push it from the office PC to the router PC, and push the button. Surely, the clients I'm working with and the client that I was shouldn't be paying the same price.

If you don't already have the proper geometry already figured out, and are unwilling to create it, then you're going to be paying someone else to create it. If they are unwilling to do that for you, find someone else who will. Even then, you are going to have to provide something. If you provide a picture of a kitchen, that doesn't provide me enough information.

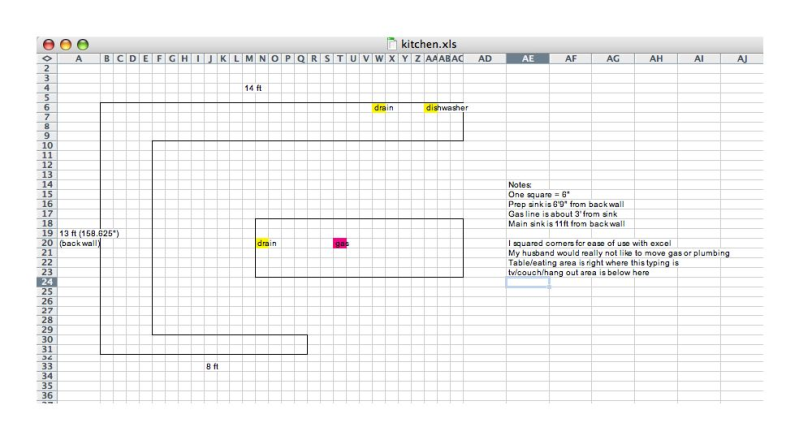

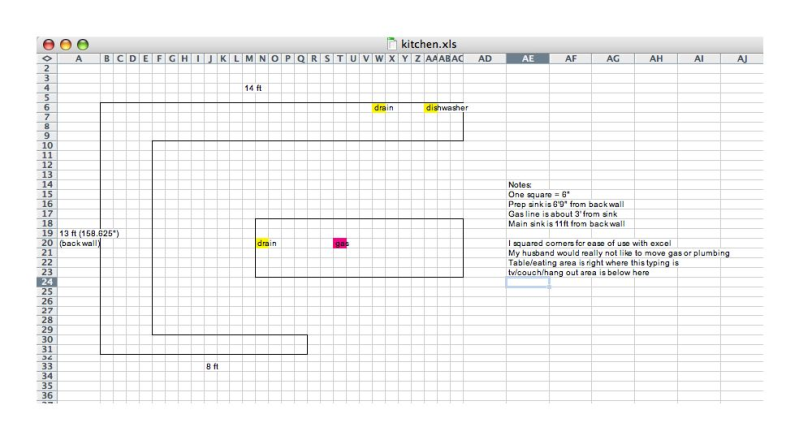

From contributor Z:

This is the document I get to bid from. I'm pretty sure we'll turn this into some work.

Click here for higher quality, full size image