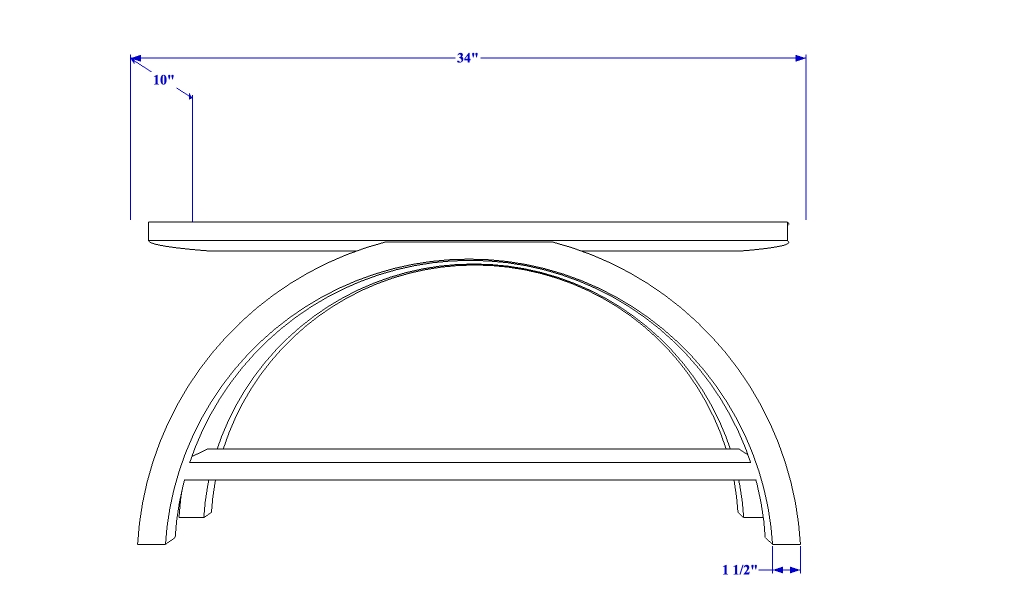

I am going to be making this coffee table. My question is what would be the best way to make the curved legs? I was going to do a segmented arch using floating tenons. Would bent lamination be better? I know a lot will depend on the look and continuous grain, but that aside will the segmented arch be strong enough?

From contributor ji

Yes, bent lamination is the way to go.

From contributor Ri

A 10" wide coffee table? Having enough strength at the top to leg connection will be a bigger concern than leg strength. Somebody puts too much force on the end of the table, you've got trouble! Drawing seems way out of scale for a coffee table too. I've never made one taller than 18". I'd also never run the legs out to the edge of the top. I like to keep them in a few inches for design and pratical matters of not stubbing a toe. I guess your estimate was good enough to get the job? How did you bid it without knowing how to make the legs?

From contributor Ki

That table looks vaguely familiar.....

I have to say that as the designer - er - maker of this table, you are the one that should best answer fabrication questions. Continuous grain or joined parts or sawn solids or veneers on glulams - What is it you want to project? What do you see when you visualize the completed table? Do you take the path that is easiest? Hardest? Or the one you know?

And really, how the heck are you gonna attach that top - drywall screws? You do realize that some people will sit on coffee tables, no? 10" wide - and this will stand up on thick carpet without being top heavy?

From contributor ma

Cross-post from "unique..."

On another note:

Who here would make a "table" with a leg-span depth of 8"?

Who would make a 36" all wood bench with a 6" width mating surface between the bench and the slab seat?

If this design was clearly speced as welded steel construction with wood veneer, would it enter into a different price category in your mind?

Looks like I was off on the 6" part... looks more like 8" in this drawing.

From contributor Jo

At an inch and a half thick, you're looking at steam bending or bent lams. Segments aren't going to fly, because you don't have room for sufficiently strong joinery.

I have to agree with many of the (unfortunately blunt) criticisms here. As drawn, it appears fragile, unstable and awkwardly proportioned.

From contributor B.

A segmented arch will be more than strong enough......if you brick lay it with 2 layers at 3/4" thick. The joints on the two layers offset by 1/2 of segment length and the layers are face glued together.

This is an extremely strong construction method.

Personally I think the strip lamination with the continuous grain will look nicer.

BH Davis

From contributor jk

Thanks for all the input about construction techniques. I agree that the drawing is crude and seems somewhat out of proportion, it was done quickly to help convey what I was looking for. When I am presented with a piece that has unfamiliar construction I usually do a full size mock up in mdf to work out the bugs. Still appreciate the input though.

From contributor Bo

This same design has been seen somewhere else on this forum recently and it's still a knockoff of designs in a Fine Woodworking article from several years ago. Same form, same shape made by several different professional makers. Lets try not to represent other peoples original ideas as our own when they clearly aren't, it's just bad for business and on a forum like this someone will recognize it and call you on it. By the way the article described several different ways to make the table, might be worth reading.

From contributor Ti

Here is one I did a couple of years ago, vacuum bagging 1/8" bending ply with cherry face veneers. I agree you need to consider supporting it on the ends. This was a dining table.