Question

I have had a Biesse Rover A point-to-point CNC for 3 years, and am looking for anyone that has tried to convert a point to point machine into a flat table. I don't intend to make this a permanent change - just when we need to cut several small parts. I think one big concern is the increased suction you need from the vacuum. Any thoughts?

Forum Responses

(CNC Forum)

From contributor D:

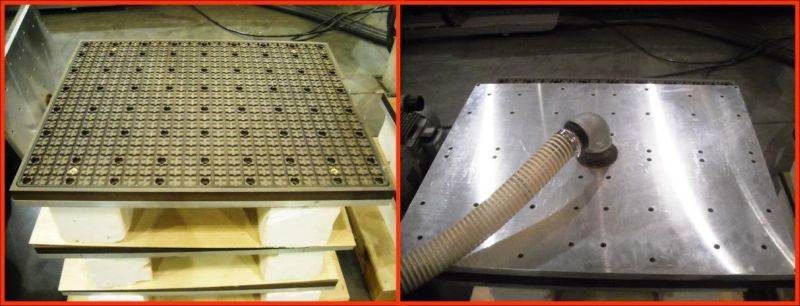

I made one with two sheets of 3/4" MDF. First I arranged as many pods as I could in a 96" x 48" area, evenly and close to the perimeter all the way around. Then drilled holes in the first sheet to allow vacuum to pass through. On top of this sheet I routed a groove around the perimeter for a gasket, then a grid network of grooves which connected all the holes and covered the surface, leaving no areas greater than 6" x 6". Think of it as one giant pod. This sheet was then painted to stop any parasitic loss of vacuum through the material itself. You want 100% of your vacuum in your grid. The second sheet, or spoilboard, is basically a sponge in use, so I use Trupan Ultralight to get maximum air bleeding through it. You'll want to paint the edges only of this sheet. It will swell and also not be perfectly flat yet, so you'll need to skim the surface, which will be your new Z. It should be skimmed occasionally to true it up and erase your through cuts. There are spoilboard cutting tools made just for this that are worth buying for the time savings.

The limiting factor in suction will not be your pump as with a flat table, but the smaller diameter lines in your rails and pods, which restrict CFM. I currently am experimenting with increasing vacuum by utilizing our powerful central dust collector directly connected to our grid board. Not looking to automate it, just routing a mechanical valve within easy reach.

It really is applications specific. I am not sure I understand the end result desired here.

One company I worked with converted an older Biesse to a flat table to make very small, ornamental product. They run 4 x 4 sheets in a pendulum fashion. They could have run 4 x 8 sheets, but the 4 x 4 sheets nested better and appeared to be much less of an ergonomic issue for them. They onion skin to within .1-.15 mm, then run the sheet through a wide belt sander with individual components dropping into a box on the other side. Typically you will use some Y axis travel on a point to point, so yield could be a factor to consider.