Cost, Overhead, and Profit: A Pricing Example

A conversation about how to price a small cabinet job sheds light on different philosophies regarding costs, markups, and the path to a life of contentment. November 15, 2010

Question

Due to market condition in California, I am trying to be very careful when giving an estimate. We are a two man shop, overhead around $2500. We are selling this job installed with 6k.

I can see it is reasonable. I would like input though.

White Mel cabinets

3 regular bas cab (14,14 and 25)

2 wall cab at 48 high (33 and 33)

2 wall cab at 36 (24 and corner unit)

One tall cab 60 high (16 width)

C Tops 1” thick 3mm pvc edgeband

Doors Wilsonart P Lam with 3mm pvc edgeband

3 drawer bank (total 10 Blum Metabox)

Blum hinges 120+

3 inch wire handle

Delivery and installation

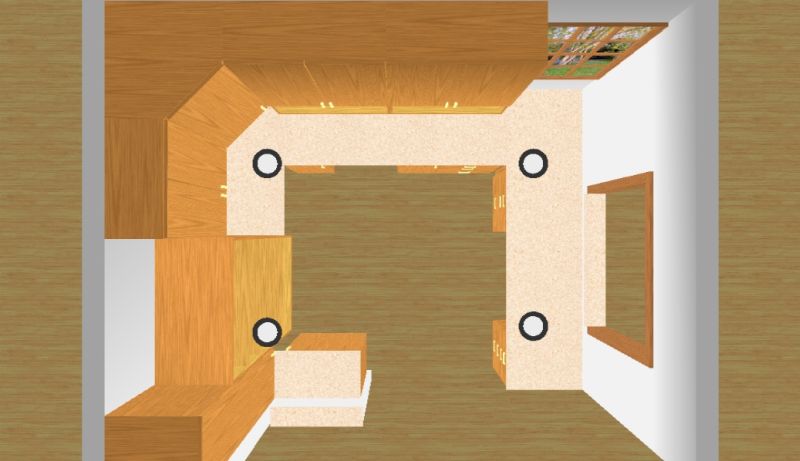

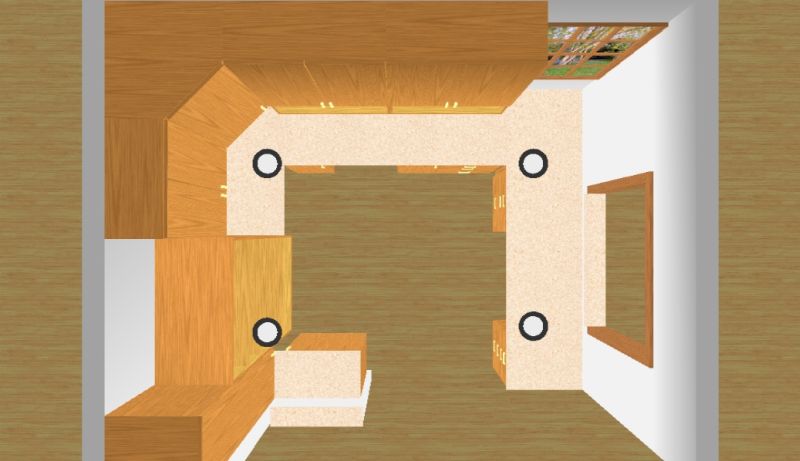

Click here for higher quality, full size image

Forum Responses

(Business and Management Forum)

From contributor M:

Without pricing it out, it sounds awfully low.

From contributor M:

This looks like a small commercial office job. Even with the 3mm edges and the U shape counter top configuration, I would do this for about $3000.

From the original questioner:

Material cost $1516, Labor 44 Hrs, that totals $2495. Adding overhead $750 and the rest is my salary and profit. That explains why I’m asking 6K. This is a commercial grade that stands daily abuse from employees.

From contributor M:

1) The material in this job is does not even come close to $1516, unless you are talking "material" to include some outsourced parts such as your doors, which, of course, would include some labor. If you are paying that much for actual raw material in this job, you are either getting gouged or there are some very high-end specs here which you aren't mentioning.

2) Your labor at 44 hours sounds about right (I figured 40 hours at $50/hr), but the rub is that that's ALL I charge, my labor. I do add overhead (much less than $750 for a job this size), but don't figure in "salary" and "profit", whatever they mean here. By the way, I do little commercial jobs just like this one at least 20 times per year. I also do larger ones, but that's another story.

From the original questioner:

Material schedule I use Cutlist plus software. Design software I use KCD (still learning).

2 sheets 1” PLam at $100 each

2 sheets Motecello maple ¾ at $112

3 sheets vinyl ¼ for baks at $20

9 sheets melamine ¾ at $26 each

1 sheet p board for nailers and t kicks at $26

3 sheets loose PLam for finish ends, bottoms, t kicks at $75

Sheet goods totals $969 WITH tax

1 roll edge tape PVC3mm 1 5/16 $177

1 roll edge tape PVC3mm 15/16 $147

1 roll hard rock maple .5mm edge band 15/16 $ 35

Metabox, Metafile, Blum hinges, grommets for PC cables, L shape brackets, etc. That is why I came up with $1516.

From contributor C:

One of the most important things of running your business is to take the time to estimate all costs and make sure you tack on time and profit - period. This way you can work five days a week and go home, have a savings account and take vacations with your family and develop a retirement account. Yes, these are very tough times and yes we are sweating bullets, but we are all better off to shut the doors and go to work elsewhere, than to give stuff away and acquire a mountain of debt. I think your job can be done for less but that's not the point. Some may say I have no overhead- good for them. But it's not realistic. I also have a very expensive bander and CNC that require parts, maintenance and payments to keep working.

From contributor M:

Using your figures I come up with approx. $4000 for all material and labor. It looks like you are charging about $60/hr. for labor, but you say in your second post that you only pay $20/hr. So that's $40/hr for labor markup to pay for insurances, etc. And on top of that you want another $2000 for "profit, overhead, and salary".

From contributor O:

I will say that you can't really compare prices unless you are in the same market, have the same supplier prices and have the same equipment, are paying the same rent, insurance, wages etc. We also have to be bidding on the same specs for the cabinets. One guy included solid dovetail drawers, the other guy including melamine with but joints. Everything in this business is a variable, for example I live in a climate where it gets very cold in the winter, natural gas prices are always changing, some winters the cost of heating is a lot higher than the previous year, or it may be lower.

Anyone living in California wouldn't have these same costs. Therefore you can’t really compare prices. This is just an example, but it applies to everything. Larger companies get better pricing on materials than smaller companies. Shops in larger cities have wholesale pricing from a supplier who only sells laminate, sheet goods and hardwood, whereas the guy in the small market has to buy his sheet goods from the lumber yard where prices are more.

Another thing to consider is work on hand, if a shop is swamped, and there are markets even now where shops are busy, there prices will be higher than the shop who has to sharpen their pencil to get some work.

How about quality, that has a big effect on the price, some guys use 1/2" shelves, 1/8" backs and 1/2" or 5/8" gables, other guys use 3/4" material everywhere. Drawer slides vary from a buck or 2 for the cheapies all the way up to 20-30 for self closing depending on the supplier.

I have seen some kitchen cabinets where the guys have bragged about how cheap they were, I would be scared to put any plates in them for fear of them falling off the wall. How about labor? You have an employee and you pay him $20 per hour and I have an employee and I pay him $20 per hour. What happens if your employee cuts and bands and assembles ten boxes per shift and my guy only does seven because he is maybe lazy or slow.

From the original questioner:

You are right, there are so many changeable facts that control how every shop gets to the final number. But there is only one fact we have to agree upon as business owners, as professionals and talented crafters. It is profit. Profit is the motive that drives me to think, create and be deferent. Also to contribute and promote woodworking industry using all what I can afford of technology and resources.

From contributor M:

My advice for you based on 35 years of doing this is for you to ignore what everyone has to say about how much you should get as markup for every different function you perform. Just figure out what YOU want to make an hour for all labor and figure that in. Add in your materials and overhead, and give your bid. Forget about itemizing everything. I would still do this job for $3000 with all services included. Granted you have already "designed" it (what I would call "laid it out"), so I would not have to do that, but every other service would be included. By the way, if I had bid this job from the beginning, I would have visited either the customer or his contractor once, drawn a pencil sketch, talked about specs and options, and given a price all in two hours or less. At that point it would be "take it or leave it".