Crown Molding Detail -- For Sloped Ceilings

Other Versions

Spanish

Calculating angles and inside corner details for crown applied to sloped ceilings. April 2, 2004

Question

I am preparing a cabinet for installation. It's going up against a back wall where the roof line begins at about 5 feet from the floor (like a knee wall). I have a center cabinet to hold the TV and two side cabinets that step back to hold components, CD's, etc. The customer wants a 3.5" crown on top. Can I chase the crown along the entire roof line? If anyone has experience with this or an alternative, I'm open.

Forum Responses

(Cabinetmaking Forum)

From contributor K:

I'd use plinth blocks on the inside corners (of the lowest part of the ceiling), if I understand you right. The higher part of the ceiling should work, though you won't get a good fit with the very top of the crown and the ceiling.

From contributor D:

The compound angle calculations that work for regular walls and crown molding also work for vaulted ceiling corners.

From contributor U:

I'd be interested in hearing more or seeing some examples of the "compound angle calculations that work for regular walls and crown molding" mentioned above...

I've searched on "crown cathedral" at WOODWEB, and cutting crown to sloped ceilings looks tricky to me.

From contributor D:

There are two different methods below. One shows you how to do it with a calculator and the other is an Excel spreadsheet set up with different worksheet tabs for different crown angles. It is all done with formulas and typical stuff is covered to save the time of having to use a calculator. You can also input your own values and it will calculate for you. I will get more into that at the end of this. Here is how I do it on the jobsite with a scientific calculator that you can by for 10-12 bucks at your local drug store or radio shack. To do this, I use a clear plastic protractor and a slide bevel. Before I buy the protractor, I always bring the slide bevel into the store and set the protractor on top of it and adjust the angle to 90 while splitting the hole at the bottom, and then flip it over. It should be exactly the same. The cheap plastic protectors can be off, so be careful. I will then also check at 45, splitting the hole at the bottom and then flipping it again to make sure it is equal on both sides.

Once at the jobsite, I use two pieces of wood about 12" long that are nice and flat and push them into the corner and then push the slide bevel into the corner and get a snug fit. I then put the protractor on the slide bevel and split the hole at the bottom and read the degrees. I divide the number I read by 2 and use in the formula below. I also need to get the angle of the crown. This is not what most people think it is, as they use the formulas on the saws. They vary quite a bit. I stick the crown in a framer's square and mark on the square the top and bottom of the crown. I then take the slide bevel and place it on the square and adjust it so it aligns with the markings and then read the angle with the protractor. At this point I have the permanent and true angle of the crown.

M = Miter angle of saw

B = Bevel angle of saw

T-1 = Inverse tangent. Read your calculator's instructions to figure out how to get this calculation. It is frequently two key presses in a row - inverse and then tangent or function2 and then tangent.

W = Wall angle. This is what the protractor says divided by 2.

C = Crown angle. This is the angle it sits off the wall. Generally it will be between 36 and 57 degrees.

M = (TAN-1(TAN*W)(SIN*C))

B = (TAN-1(SIN*M/TAN*W)

It is actually much easier than it looks and you do not need to understand the math. You do it like this in your calculator:

1. Get your C value and write it down

2. Get your W value and write it down

3. Input the W value

4. Press TAN

5. Press the memory save button

6. Press clear

7. Input the C value

8. Press SIN

9. Press X (times)

10. Press the memory recall button

11. Press =

12. Press the inverse button

13. Press the TAN

14. This is your miter angle. Write it down rounded to 1/10th of a degree (if it was 38.34567, you would write down 38.3).

15. Press clear

16. Input the W value

17. Press TAN

18. Press the memory save button

19. Press clear

20. Input the M value you just wrote down

21. Press SIN

22. Press / (divide)

23. Press the memory recall button

24. Press =

25. Press the inverse button

26. Press the TAN

27. This is your miter angle. Write it down rounded to 1/10th of a degree (if it was 18.74587, you would write down 18.7).

You now have your miter and bevel angles for your saw. This works just fine for vaulted ceilings and the whole process is very fast. It is not nearly as time-consuming as it appears here. With paint grade crown, you can measure your angle to ½ degree and for stain grade, you should work to ¼ degree and they will be exact and tight.

If your saw is not perfect, you may have to introduce a fudge factor. Typically it is something to do with the bevel angle. If it does not come out perfect, adjust your bevel angle in 1/4" degree increments until it is correct. Once you get it, let’s say your saw bevel is off 1 full degree, then just add or subtract that 1-degree all the time when you set the saw.

The link to the spreadsheet below is for quick reference. The formulas are put in differently to accommodate the difference between Excel and a calculator.

Each tab has two crown angles. The first one is 36-37. On this tab you will see one column on the left and one on the right. All the typical cuts for 36-degree crown are on the left and the typical cuts for 37-degree crown are on the right. Each crown angle is broken up into 3 sections. 90-degree corners, 22 ½-degree clips and 30-degree clips. The highlighted area in each one is the full typical perfect angle input number to put in your saw (where the angle of the wall is a true 90 or 45 or 30. Each section is broken down into different settings at ¼ degree increments and the list goes up and down a full 2 degrees in each direction.

You can print it out and take it to the jobsite. If you know the angle of your crown (let’s say it is 51 degrees and the wall angle is 88 degrees), you would go to the tab with 51 on it (you will be using this sheet again and again now for more cuts) and then look for 88 degrees. It is on the top right.

Then get your saw settings:

Crown angle - Wall angle - Miter - Bevel

51 - 88 - 38.83 - 29.85

You can always just type in a wall angle number in the spreadsheet and it will calculate it for you, if the angle you need is not already there.

The way you deal with this for vaulted ceilings will become apparent as you do it with a calculator.

Download here:

http://SmartLister.com/Files/crown2.xls

From contributor M:

I don't understand how these calculations can work for sloped ceilings too, since you aren't measuring the slope of the ceiling. I think it's unfortunately even more complicated. Or am I missing something?

From contributor D:

What is different here? The crown will set at the same angle off the back wall. The only difference is the angle of where the walls intersect each other. Get the angle there and plug it in.

From contributor D:

Use the slope angle. Maybe it only works with the slope angle when the corners are true 90 degrees. I know it works because I gave the formula to some guys running crown on the outside of a house and said I did not know how the vaulting issues would figure in. I came back later and they were done. They said they just used the formula and it worked. They would not have pulled my leg, as they were very happy about it. It was very simple. Just try it on some test pieces. I do not have a compound saw right now so I cannot try it.

From contributor P:

Contributor K has it right - you cannot do this because of the angle on the gable meeting the perpendicular wall. The only solutions are to but a block in the corner or turn the molding on the lower wall flat to match the molding on the gable.

Contributor D is just trying to make things more complex, and always trying to preach the values of parametrics over the simpler methods :-)

From contributor D:

I guess it all depends on what you want to do. Plinth block can be nice. This is especially true if that is the look you are after.

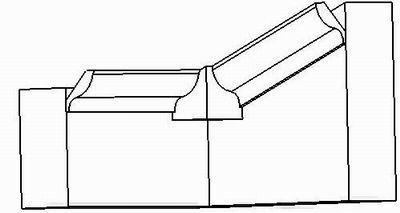

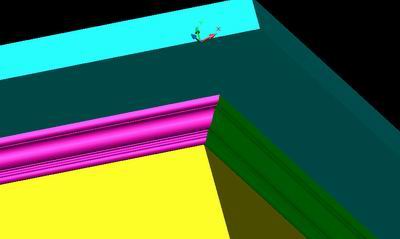

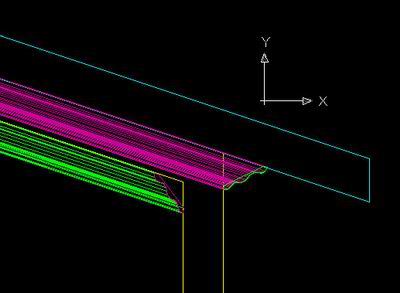

Here is a view from further away without the plinth blocks.

From contributor D:

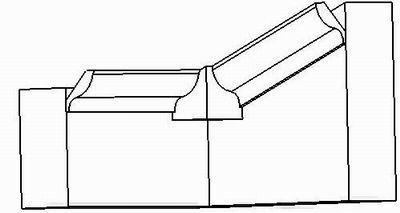

The formula does work, but you must adjust the crown angle. This is easily figured by measuring the angle of the vault. If the angle is 18 degrees, then you must tilt the straight wall crown half that amount (backward), 9 degrees, and then tilt the vaulted wall crown forward 9 degrees. Optionally, you can tilt one the full 18 degrees. I did it the half and half way. The naked eye can barely tell it was tilted and is only drawn to the corner where they align. You may want to back-cut the top back edge (unseen) of the straight wall crown so that the front top edge is tight to the ceiling. The rest is up to you.

From contributor D:

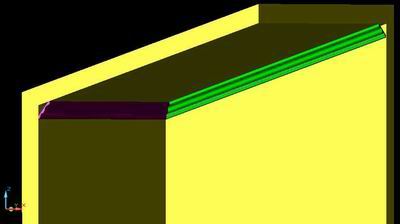

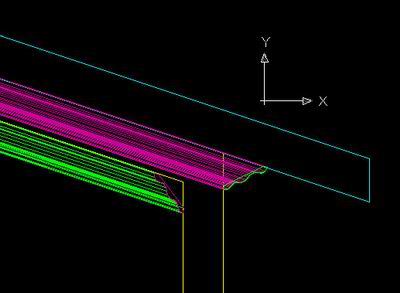

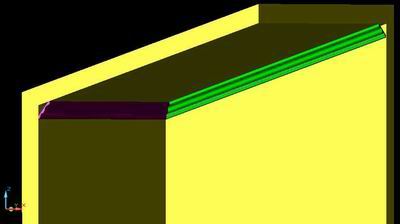

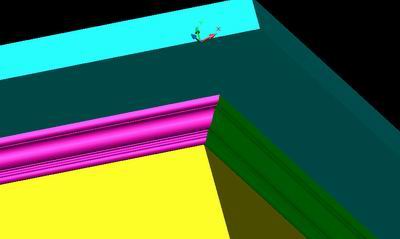

The guys I was talking about earlier were doing an outside vault. As you can see (I did not shade it), the crown on the straight wall is tilted. Both pieces were cut on a true 45 and then rotated into place. This looks fine on an outside miter and it is all you need. I never even noticed that the outside crown was tilted the extra full amount because it looks correct in relationship to the overhang above. I do not think this is the best way to do an inside miter on a vault, but you can do it this way. You just have to tilt it inward, instead of outward, the full amount. By doing that, you only need the formula and to measure the wall angle at the corner just like if the ceiling was not vaulted.

From contributor D:

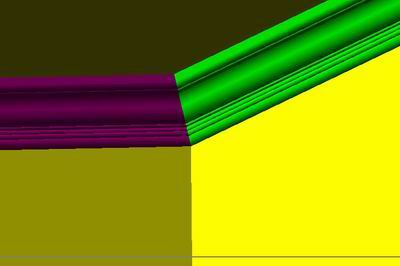

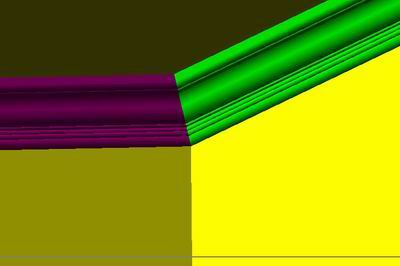

Here is the view angle from below with it shaded and a bit closer up. Looks fine, doesn’t it?

From contributor M:

Thanks. The tilting of the crown makes a lot of sense, and I believe that it would not be very noticeable. I hope I remember this if or when I need it!

From contributor D:

You're welcome. I was incorrect to say that the angle to the wall stays the same. You would still use the same crown angle at the wall for figuring in the formula, but you would not nail it on at that angle. You were right to question it. I certainly learned something here. Thanks! This leaves us four options that I can see:

A. Use the standard crown angle at the wall and tilt the crown as much as necessary for the straight walls.

B. Split the difference of the crown angle to the wall by dividing the vault angle by 2 and adding or subtracting this 1/2 difference between the crowns. I do not know how this would be input in a calculator, but cutting a few pieces would answer this fast.

C. Use a plinth block

D. Add a short piece that is similar to a self-return to allow us to split this difference on the vaulted wall at the corner.

Perhaps there is even more...

From contributor G:

Running crown molding up a cathedral ceiling, as you want to do, isn't that tough, but you can't just cut two angles on a compound miter saw that will magically make it work, because the crown is running in two different planes. In order to join the two planes, you must eight tip the horizontal crown to a new spring angle so it matches the 'length' of the miter on the rake crown (which looks terrible and on a steep ceiling requires two different sizes of crown with the same profile) or you must cut a transition piece between the two planes.

From contributor D:

Contributor G, I guess it is a matter of the look you want. I can certainly see your point about the look if the vault angle is too steep. All and all, I do not like the transition piece. I would opt for a decorative plinth instead, if I could, and just cheat the angle on the lesser vault angles. Splitting the difference will also allow for a steeper angle before you get into a bad-looking situation. The situation with using two different crowns would require custom knives and a CAD station to scale the crown appropriately. Then the profile would have to be rotated to the cutter angle of the machine to get the exact profile when cut. The chances on this ratio being exact to match your vault angle is almost none. It is doable, but not cost-effective for the typical job.

From contributor D:

Correction:

In the post above, "The chances on this ratio being exact to match your vault angle is almost none."

Should read: "The chances on this ratio being exact to match your vault angle with two different off-the-shelf crowns with the same profile, but at a different size, is almost none.

From contributor P:

I learned something… I didn't think of splitting the difference or the transition piece. Thanks.

From contributor G:

Contributor D, if you look at many historic homes, you'll notice that the crown molding on the eaves, when it turns the corner and runs up the gable, is formed from two different sizes - the rake crown smaller than the eave crown. It's been done that way for centuries. I've done it that way inside homes many times: used 2 1/4 S-Cove crown on the gable or rake, and 3 1/2 or 4 1/4 (depending on the rake) on the horizontal runs. Of course the spring angle still must be dialed in on the horizontal run, though you can often keep it close to the desired angle when you use two different sizes of crown, but I've never attempted to cut those inside miters on a miter saw. I've always coped them because it's a bastard cope and a difficult one.

Also, just to be sure we're all on the same page: if you use a decorative pendent (a plinth is something at the bottom of a column, as in 'baseboard'), then you don't have to "cheat the angle" or "split the difference" of anything. I like the look, too, but it's definitely Victorian/Gothic and not at all right for every home.

Frankly, I find the transition to be a finish carpentry challenge: when cutting crown in position at your saw, the inside corner must be cut with the molding upside down in your saw (the way crown is normally cut in a miter saw when it's in position), but the outside corner of the transition piece must be reversed before cutting - it has to be positioned right-side-up in the saw. There are other aspects to the process that I also find challenging. Still, everyone has their own idea of what looks good.