Cutting Speed when Milling Aluminum on the CNC

Advice on bit choice and operating settings to make good time when machining aluminum plate on the CNC. May 27, 2014

Question

(CNC Forum)

WOODWEB Member:

Can a wooden CNC machine mill harder material? I've made many projects with hardwood, but I never tried to machine harder material.

Forum Responses

(CNC Forum)

From contributor K:

This was 2005.

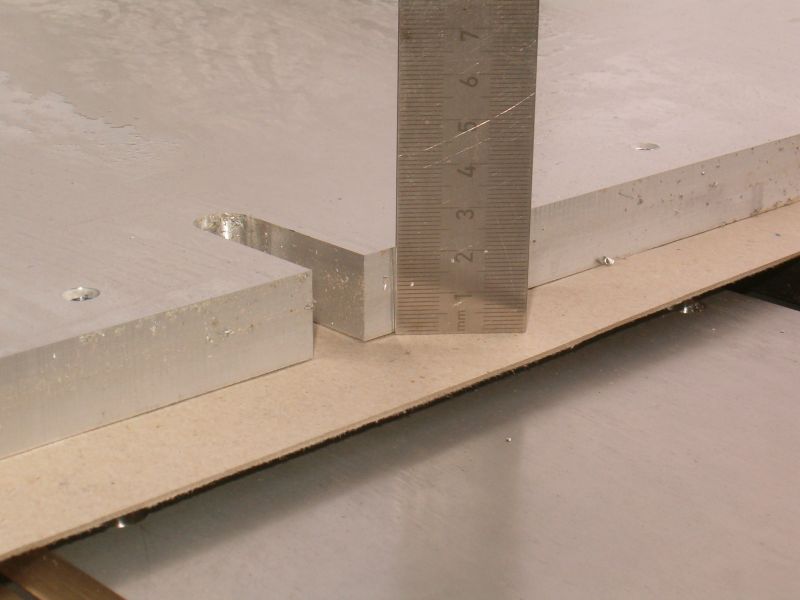

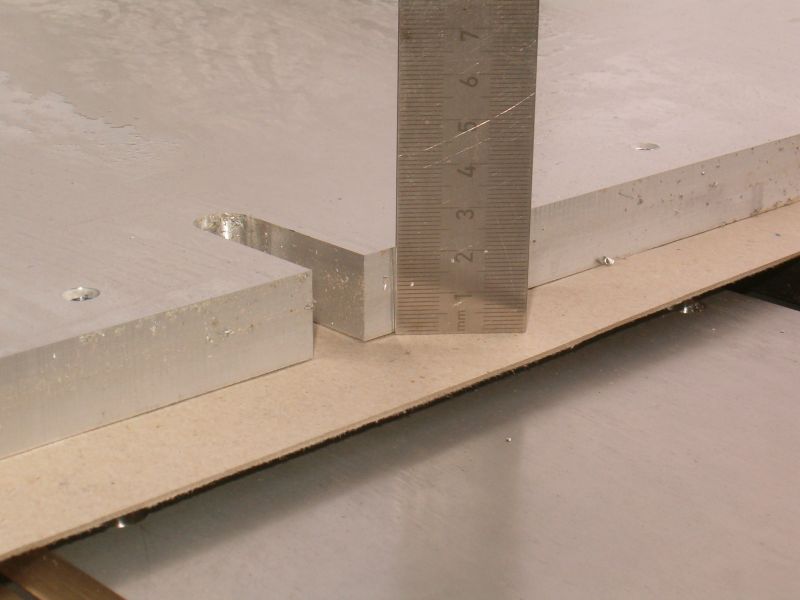

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor T:

Judging by your chips, you're going too slow. Basically you're re-cutting the chips and grinding them to dust. Try an O flute and let it rip. The chips should rooster tail out the back. For coolant, try a mister system with rubbing alcohol. Save you a lot mopping up. At the right feed and speed, most of the heat will be leaving with the chip. Type of aluminum makes a big difference as well. I always try to get T6 6160 cuts real nice.

From the original questioner:

Very interesting information, but is the machine in the picture built with plywood?

From contributor T:

Never ran a plywood CNC. But you could run single flute tool to make up for the lack of speed. May even be able to increase the depth of cut with single flute. I think you can get more out of the machine by dialing in your tooling, feed rates, toolpath strategy, material, coolant, etc. There are limits but if you play around a little now, you can save yourself some time to do more projects. Faster is always better. Whether it's a hobby or for money.

From the original questioner:

I just ordered new single flute carbide end mill. I will test when I will receive them!

From contributor T:

Be sure to ramp in your entry points or drill out some clearance for your start point. Diving right into aluminum with a single flute tool could break it. Good luck.