The cat knows who's meat it ate. I think...

Seriously--- some marvellings over shop space allocation. Just because it is a hot topic in our shop--we use to have a bigger space, but then they moved, to a smaller space, everything is crammed... "this is stupid" they say.

Is it really too small? What I see is a huge mezzanine full of returns and crap and unsorted laminates. The moldings get stored there, but get handbombed up a flight of stairs because the gate opening is jammed (that is somehow the end of that story) so we can't fork it up.

The floor space is only used on a horizintal plane. Nothing is stored in height. There is a ton of height space.

There are machines and large devices that haven't been used, in at least the last 6 months, just sitting there. Some of them are blocking infeed of saws. Paint shop has no stoarge for drying items, so they get chucked unto the floor.

Trucker needs to dig for tightly stored items, he pushes stuff away. I start everyday condensing stuff on wheels (or not) out of the way of infeed and outfeed of commonly used machinery.

One could look at manhours, cost out the price of shuffling. But I'm also wondering about the price of frustration from everyone always "pushing crap out of the way". It is a bit of a shitty way to start/ go through the day.

Anyone else's shop look like this? Anyone else's shop use to look like this?

From contributor ti

A good set of observations Mel.

One of the best things we did for our shop was build custom palettes to hold our machines. We have a fairly narrow, low profile pallet jack that will pick up a couple tons. We put as many machines onto pallets as we can. This helps for moving lesser used machinery onto the floor when we need it or pulling out often used equipment for maintenance and cleaning etc.

These palettes are accessible from all four directions. Since the support mechanism is on each corner you can also access it diagonally. The easiest way to make a palette is to start with 4x4 posts. This is way easier than building up four courses of 3/4 plywood blocks. We do use 3/4 plywood for the top however.

The next thing best thing was to build about 40 low carts on castors. This makes moving cabinets around the shop floor a breeze and, except for long cabinets, a one person job. If you shop around you can usually get castors pretty inexpensively. Don't confuse inexpensive with cheap. You want a good quality caster. You don't necessarily need locking castors but they do need to swivel all directions. Setting up shop carts with two fixed castors and two swivel will frustrate you eventually.

The next thing I think we will look at is a walk-behind fork lift. The office supply store has a forklift like this that efficiently navigates narrow corridors. It's about the size of two shopping carts yet can easily lift a pallet of typing paper ten feet into the air and elegantly load both sides of that narrow corridor.

As you pointed out, you are already paying for the air. Might as well use it.

From contributor sc

Tim,

I have been looking for ideas for moveable bases or something for some bigger machines like the widebelt sander. Do you have any pictures? Sorry as i do not mean to hijack the thread. Thanks

From contributor ti

You should see if you can find Paul Down's exposition on the forum archives about a transition they made to lean. There were a fair number of great responses in that thread but he did a particularly good job of keeping it focused and articulating the transition.

The first thing they did was kill all the things that weren't helping. If the detritus wasn't adding value it was subtracting value so they sorted it out of the building.

Kilgore Trout had this to say about that:

"There is a rational and scientific reasoning behind neat workspaces. Yes, 'neat' is a relative term as we see from above.

Using a powerfeeder on a shaper reduces our needed attention - brain power - to do the task without the feeder. We can limit our attention to sticking in the right end, the sound of the cut and when and where the next piece is. Hell, we might even get a little bored if we have to do a lot of pieces. Without the feeder, we have to do the above, but also push the stock through in a steady and even flow, Insure it is tight to the fence, insure it is on the table, keep our hands out of the way, avoid tripping on that cord, and probably more. In short, the feeder is doing more than feeding the stock - it is freeing us up to focus on what needs to be focused upon. Or to be bored. It has eliminated some of the clutter in our brain to the point where we have 'empty' space on our personal hard drive.

Just as your computer can track business functions far better than you can on paper, and frees up time for other things while it does the mundane for you.

Visual or physical clutter takes up space in our brain, just as data does in the computer. Our eyes/ears/other senses are taking in all that info, even though the bulk of it is not useful to the task at hand. Space that could be better used instead of seeing those cabinet doors leaning over there, just at our peripheral vision, hearing that Hendrix guitar solo. Given enough visual and auditory cues, we would say we are distracted. The truth is that the distraction actually happens much sooner in the brain than we may consciously realize. At a lower threshold that is noticeable. That is, we are bugged by whats around us and may not realize it.

Some of the first scientific discoveries in this area helped give rise to Minimalism.

We learn to ignore and filter since this is true when driving (want to talk about distracted driving anyone?), walking, eating or doing about anything.

Frank Lloyd Wright said he could design a house that would cause the inhabitants to divorce, but there was no need for him to do it since there already so many houses being built that way. This was at the start of what became the huge increase in the US divorce rate in the late 1950's as well as the growth of the tract style ranch house.

But paring down the 'noise' and the clutter in our environment does enable a more clean and clear thought process. With practice and effort, this process can be more deliberate and directed. I think anyone could agree that this would be desirable in the wood shop."

- See more at: http://www.woodweb.com/cgi-bin/forums/business.pl?read=773103#sthash.FM302uLk.dpuf

From contributor ti

Scott,

We have a two headed 42 inch Butfering wide belt sander on a couple of 8x8 timbers.

We have moved it around the shop a couple times now with two palette jacks, one on each end of the conveyor belt. You need about 4 four guys to make it work mostly for moral encouragement.

From contributor Me

If my kid wasn't napping I'd probably be cheering at my computer screen like a sportsfan.

I for sure find that the elimination of clutter is tremendous for both productivity and straight up mental well being. Ever try to cook up a complicated recipe for the first time in a messy kitchen with someone yapping idly at you? Holy brain strain.

I remember when I started working at this shop. Watching pissed off people, juggling madness, trying to get to the machines they need with minimal effort on shuffling. Weaving 10 foot lumber through cabinets into infeeds. Pump out the product fast, we need to produce, produce, produce.

Simple thing, but liberating infeeds and outfeeds before you actually need the machine has been huge. Now I'm curious about the next step--tweaking the other less blatantly screaming innefficiencies in space management to see what sort of effect it has on production.

The palatte idea is genius. I'm definitely going to plant that seed and see if it gets a bite. And I'm fixing that jammed mezzanine gate even if they try to pry me away from it, kicking and screaming, the whole time.

Scott, no worries, not a highjack at all. Totally on topic and good question.

From contributor La

The best thing we ever did was to put conveyors in the panel processing part of the shop. We also eliminated the practice of making a few extra parts "just in case." In case of what? sloppy handling? If you have a very small shop just being organized in the order of production so you can just use a work surface that serves as the out put from one machine and the input to the next works. Never move a part unless you are increasing its value. Keeping damaged or extra parts is a total waste. Eliminate making them in the first place. The finished cases go directly onto shipping pallets wrapped & labeled. If you ship blanket wrapped then you may need to use 24 x 32" low carts that are designed to stack when empty so cases can be moved into and out of temporary storage while the job is accumulating. I haven't figured out a good space efficient system for handling wood processing at the relatively low volumes that we use. Machines are setup to utilize the same infeed & out feed space as much as possible. Ordering by job only works to a limited extent here also.

From contributor Me

This keeping of returns is just bizarre to me. We have an entire mezzanine full of rejects from the last decade. Almost as if throwing them away would solidify the fact that they were failures. We all know that eventually they will get thrown out. Might as well do it now, I beleive.

And the extra parts for just in case... We have a guy there that is notorious for just-in-casing. The freaking stuff was all over the place. 10 foot long raggedy lumber left over strips planted all over the place because what if we need to make enough mesh strips to supply every speaker cabinet in the country? Never know!

I admitedly threw everything out when he was sick one day. A little tactless?Probably. Nice clean storage areas? Definitely :)

From contributor sc

I used to work for a guy years ago, he has been super successful in business. He has his guys clean the shop for a couple hours in the middle of the week and at the end of the week. Before the Christmas break he gets a couple large bins dropped off and everything gets thrown out. The shop is thoroughly cleaned. He says that all the off cuts just take up space and get moved a bunch of times so it is cheaper and easier to just get rid of it. Makes for a clean and tidy shop.

From contributor De

Put a monthly value on the space that is taken up by clutter then compare that to the value of the items occupying it. Once I did that i had a lot easier time getting rid of things. I also had to remember that even though the item cost me $100 to aquire, it is no longer worth that amount most of the time 10 cents on the dollar. schedule regular time for clean up and improvement we do it every Tuesday morning for about 1 1/2 hours and it really helps

From contributor Me

Derrek, I think that's probably the answer right there? So is it as simple as:

x=area of old crap stored

y=total area

r=rent

x/y=ratio of wasted space (w)

w * r= money lost saving crap?

From contributor Pa

You're only losing money on piles of crap if they are preventing you from putting the space to profitable use. There's an up-front cost associated with cleaning up that should be considered. It might be better to look at why you are producing unsellable work in the first place. Solving that problem will also require resources, but will have a bigger payoff down the road.

From contributor Me

Paul,

The cost of cleaning and clearing is definitely what is holding us back with the manager types. But I'm pretty sure it's a knee jerk spending fear and not a calculated cost/benefit. As you smartly asked--we are indeed in deep need of space for everyday production. And so busy no one stops to breath or think about it.

You are for sure correct that my xyrw equation does need to be balanced against price of shuffling... So would my xyrw result perhaps give my an eye ball budget towards the cost of man hours for reorganizing given there is no cost in materials? Or at least give me a feasibilty glimpse?

From contributor Me

Oh and Paul to answer your question about the unsellable work--it's no mystery for us. Sales are strong, talent is strong, product is great, location is smart, but production isn't at optimal organization and has too many contingencies to deduct an accurate timeline for production. We piss people off by being late sometimes, they cancel. Sad, no?

From contributor Ti

Mel,

What do you mean by "production has too many contingencies" to become predictable? Is your work all one-of-a-kind?

From contributor La

Best I understand is your problem is a lack of organization, not space. Too many contingencies? Even if you have a very diverse range of products you can have a system that works for at least 80% of them, over & over. Isn't your software producing parametric designs? If there is not enough time to clean house every week its because you haven't been doing it. A week's worth of crap doesn't take all that long to get sorted out and dumped.

From contributor De

Paul, agreed that there is a cost to cleaning up and you need to use that space for profitable things. There is also a non tangible cost of having employees work in a dirty cluttered mess. A nice place to work and a place your employee's take pride in will give you a more productive work force. Our showroom is on the front of the shop and I take customers out into the shop all the time to see how clean and cool it is.

From contributor Me

Tim Schultz, you insightful bastard :) So no, not at all,there is absolutely no reason for all of these contingencies. There is custom work, but no where near enough to justify this. The contingencies all lie in severe disorganization in production. We are talking right down to machines, expensive high end ones, blowing up from lack of maintenance.

And there is so much middle management (4 middle managers for 8 workers) that I can't make head nor tails for what is actually going on and who is making the (not so good) calls on what, for what reason.

All I see is that it isn't as good as it should be.

And I'm killing myself looking at them because I have been trained in a very neat and tidy international LEAN manufacturer.

But who am I to judge? I have 10 years of post secondary education and one hell of a career for my age. Can I judge ground-up local people for not being there yet? A step at a time....

Seriously Tim, on some days I think I can do it, and know what its worth to bring a stubborn family business to the next level, but on other days I think I should go be a very relaxed pawn in a very clean shop.

I just spent the last hour looking at the websites of all of my most favorite people on this forum, thinking "holy shit, we all agree and look at how well their shop is going. So clean..."

Can a little girl turn a seasonned shop of hardened individulas around? I really don't know.

From contributor sc

Mel,

What is your exact job description? What are you being paid to do?

As for your question, the answer is for you can change the culture and the way things work around there. It is no different than climbing Mount Everest. Slow and steady. Each day, or week you add a little extra or do a little more. You are not going to race to the top or change the whole shop in a day or a week.

As for the manager problem that is a ratio of 1 manager for 2 workers. That is totally out of wack. If you read anything about span of control the ideal ratio would probably be closer to 1 supervisor for 3-7 workers . A lot of shops I know it is even a lot higher. There are a lot of factors to consider.

From contributor Me

Scott, sometimes I think I need to get "slow down Mel" tattoed on my hand...

Thanks, that is golden advice. Good way to start the week.

Happy Monday :)

From contributor Pa

Mel - before you kill yourself trying to reform a bunch of dinosaurs, you should make sure that somebody at the top will appreciate your efforts. If not, then spend some time right now looking for a company that appreciates motivated, intelligent workers. I've run into this before - great employees in the wrong company. You owe it to yourself and your family to find the right employer.

From contributor Ti

Mel,

You are a real fireball! You have surprised and impressed all of us. I hope you can maintain this enthusiasm long enough to get enough experience to put a proper tail on your kite.

What I would recommend for a young woman such as yourself is to learn communication skills. You already the big picture figured out, you just need to learn how to mine the data. Learn how to create a database or build a video. You need to leverage this enthusiasm and put it to work for yourself and this community.

Woodworkers are one of the few professions left still much like it was when the European settlers brought their craft to this country. All you had to do back then was hang out a shingle and, if you were useful, you were in business. By and large the restrictions on this industry are not a whole lot different now than they were back then.

This is an industry ripe with opportunity precisely because it is still, as Paul puts it, so filled with dinosaurs. As John Wayne put it, "You gotta be tough if you're gonna be stupid". You got to have some extra money in the bid if you're going to subsidize stupid.

When Texas was being settled you had hire a woodworker or else you had to eat your dinner sitting on your saddle. As the wealth continues to concentrate the opportunities in this industry will continue to grow. You just have to be one of the smart mechanics to harvest this opportunity.

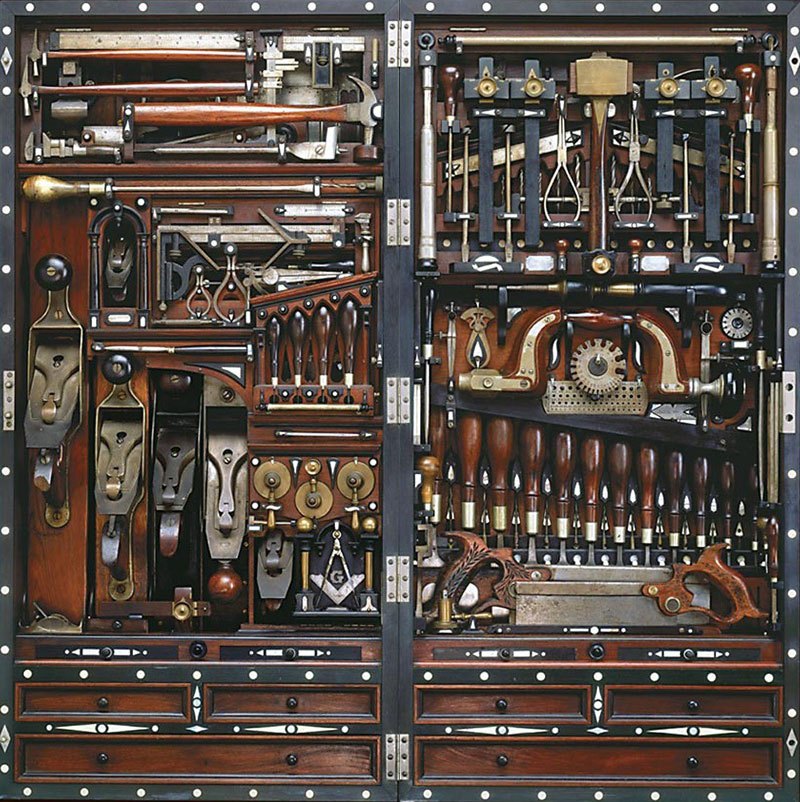

From contributor Pa

Here is Tim's tool box.

From contributor Ti

You got it all wrong Pat. I do my chiseling with a pencil.

From contributor Me

New development.

Two weeks ago the angry foreman displayed unnecessary aggression one time too many. I called him a "mean adjective + bodypart" and walked off. I wrote a nice letter to the owner, that I didn't really know well, about aggression in the shop. Told him I would not come back untill we discussed.

Met with the owner and was absolutely impressed with him. He is a reasonable man with a very good sales background that is admittedly a little at lost with the production aspect of things. He promoted in the shop internally but is just not getting the results and isn't sure what to do. He knows its not working. Last week I saw a team of consultants poking around in the shop. There is hope.

I've been skirting around the issue perhaps because this is a forum and I hate to publically point a finger even if this is anonymous. But I know the problem is middle management. For sure. They are unsure, unfocused, inexperienced in management, and there is too many of them. And I think (know) they may be battling over turf and neglecting things in their neurosis over social battles.

The crazy part is that I actually do know how to collect data. And I write a mean proposal. When I had my corporate stint, I was just doing a 9-5 because my first love, the events industry, had died during the recession. So I needed work. Picked up a warranty position for a major manufacturer.

After 3 months, wrote a proposal to agglomerate quality control and warranty data to better identify product weaknesses. Went through. Set up the meetings, the new database sheets, set up the employees for the new method.

Wrote another proposal to work on military gear division as a subset of warranty maintenance. Wrote another one to get a scumy salesman off the military division because his lack of knowledge resulted in returns that he was trying to bully warranties into eating into their budget. He did get kicked off.

Got promoted to learn and tailor-make a new logistics position. Wrote a proposal for IT to create ERP tracking of shipments. Passed that one too. Got my own ERP tab for it too :)

The director of production then sent me to school to learn LEAN manufacturing standards. He wanted me to finish standardizing the logistics position and move me to production planning.

I figured out a system to track shipments and changes in lead times that only took 20 hours a week instead of the scheduled 40. That also took a good strong proposal.

But then the events industry picked up again and I got called back to it. Pays so much more, so much more freedom, so much more fun. Plus I could live on my boat and be a gypsy and fatten my bank account.

Enter the child... yeah we had a kid and everything changed. Shocking, no? We bought a house and the hubby has been leading a hell of a corporate career since. I've been back to the 40 hour regular paycheck thing.

So here is the question--I know for a fact that if I keep asking questions here, and using my LEAN background, and write a good proposal (s) to the owner, who has also worked for a major retailer in the past, shit will move. I know it.

I don't know if this is silly but I'm a little intimidated about doing it. Bypassing all those anxious middle managers. And this is blue color--I'm not sure that it's as simple as best proposal wins and everyone just shuts up and follows. Not sure what my actual day-to-day would look like if I go that route.

On the one sense, I stay patient and help the culture, which really, I know I already am, and watch everyone feel awesome and grow as a team and triumph. Feels super good right?

In another sense, feed my impatience and just slam the junk on the table and write me one of my mean proposals that people seem to like so much.

Probably both. I need to find a way to both reach the owner and empower the struggling middle managers. I'm pretty sure I can do that.

Most aspects of my life are pretty figured out. I just like progress and complex human problems. And I really, really, love me a well oiled machine, especially if I oiled it myself.

I think that if I can tackle this, it would be even better learning (and way cheaper) then an MBA.

Btw-- I think about what you guys say a lot. This has been very constructive and fun for me. Thanks for not being mean internet users and entertaining my questions :)

From contributor La

Changing culture! Been fought here, but i'm as guilty as anyone. Some days seems not worth the effort. It isn't in the short run but long term even small improvements add up. The small improvements though, need to be based on an overall scheme to have the most value. If you haven't convinced the proper players of the value, you will fight the same battles over & over.

From contributor Pa

Wow, I'm impressed. In order to digest what you said a little better, can you tell us more about your company? How many employees, gross revenues? How many employed in the office, how many on the shop floor? Shop and office square footage?

You might be just the person this company has been crying for, and you're definitely a rare bird in the woodworking industry. You remind me of my operations manager, who is a young guy but extraordinarily talented, both at doing work and at organizing the other workers. Even though he's years younger than most of my workers, I put him in charge and we've made enormous strides. I think that, aside from his abilities, the keys to his success have been:

1) I get along with him very well, and

2) So does everyone else.

In order for your ideas to gain traction, it's important that your colleagues get on board with the new ways of doing things. If the middle managers in your company have a lot to lose if you succeed, you may be in for a very hard time. If improving operations makes everyone better off, it will be much easier.

From contributor Pa

I was thinking the same thing as Larry and Paul,

Less talk of bypassing middle level management and arguing with the foreman and more PR and tact is what you need.

Making enemies out of people who have no reason to be your enemy is not a good idea. People and systems are not changed with force even if your proposal is accepted you still need the willingness of your people to do the work.

A little known fact of management is the only stock in trade a manager has is willingness.

From contributor sc

You have some good ideas and until you try you won't know if your plan and proposal will be a hit or not. You have to be prepared for a few different results with something like this. You may have the answers they are looking for, but you may also have ideas that are exact opposite to what they are looking for! (Right or wrong). As for the MBA you may have the same solution or ideas as them, the difference is they are more likely to listen to an MBA. Good luck.

From contributor De

Paul, i agree that sometimes you need the "how to win friends and influence people" approach. Sometimes though you also need to take the "fire someone today" approach.

For lean to take a long term root in a business, first the leadership has to buy in to the lean way of doing things not just bottom line. Second the work force must also buy in, with good leadership and training, and be willing to improve the process. In some cases people don't want to put in the effort to improve or aren't the right fit for the team. Sometimes you have to make them free agents so they can seek out better opportunity.

From contributor ca

Mel-

Write the proposal. Include the free LEAN path, include a cost analysis of ERP that can "Dashboard" for all management, and users and propose a restructure or "Asset-Re allocation" of bodies to bring up production and reduce costs, chaos and clutter.

If you can implement a cross feed of ERP to accounting and the design software, you would cut a lot of expense fast.

Write a proposal where everyone wins, including you, because, it's your fresh set of eyes. (Not the inexperienced, internally pushed people).

From contributor Me

oooooooo this is getting really, really, interesting.

All these diverging opinions do somewhat represent an internal struggle of mine--go balls to the wall or play it polite and slow. I'm better at balls to the wall. I know it. But I like these suggestions of temperance too- they remind me to be kind and I like kind. But I think I can do kind fast?

So Pat, you bring up a very good point, that I'd love to bounce off all of you.

So what is the roll of a little bit of confrontation? It's yeilded gold for me. I know that it is a little unorthodox, but please, please have a read before you judge (too harshly).

I wish to the bottom of my heart that I was a smooth operator. I hold on before getting harsh, a long time, but I've got a breaking point where the natural comes into overdrive and everytime, it somehow yeilds gold. (Though I'm also still afraid of it despite repeated successes.)

For example, this situation with the foreman. Yes I called him something harsh, Yes I walked out. Some of you are probably imagining this situation that you've all seen--somebody gets mad, holds on to it, becomes uncompromising and makes a complete fool of themselves.

It doesn't have to be that way. That conflict with the foreman has turned into a very positive thing.

I would like to specify that my loss of temper was after watching completely beligerant aggressive blow outs towards all staff members, since I have been there. Screaming, breaking things, etc, sometimes over mundane details.

The conversation with the owner wasn't along the lines of "this is messed up, fix it." It was along the lines of "I beleive this is getting out of hand and that we just need to establish a dialogue about it and see where it goes".

Great talk, smart man. Went back to the shop to get back to work, and was greeted with immense warmth from everyone, including the foreman in question. He has made an admirable effort to increase his level of pleasantness. I find this impressive--lets face it, I had a conversation with his superior about him. Hard pill to swallow. But he gave me one of the nicest appologies I have ever received. It was honnest, and downright human.

I have been open with all of this with all of the coworkers. Told them all how fair the owner had been, how kind the foreman was being. They had all been the brunt of the aggression before and were all motivated to see that it was a fixable problem. Also let the owner know about the foreman's impressive turn-around.

Since that I am seeing little changes everywhere. Lots of happy floating around. Cooperation between people. Less blame games. Tidyer work spaces somehow. I'm completely amazed by how fast this is happening and hope this can stick.

So I don't know-- I always allow that I may have my head up my rear end. But I do not think there is one-code-of-conduct-fits-all rule. I think you sometimes have to drop the hammer but that after you have to deliver the best finess you can muster.

Any thoughts?

From contributor Me

Paul, as for your questions I'm not exactly sure on their exact revenue, but do know they are doing remarkably well despite the disorganization and anger. Strong product, strong sales.

The exact size, not sure on number--but to give you an idea, there are two showrooms, 2 offices. The shop contains a CNC, a panel saw, 4 table saws, an edge bander, 3 compound miter saws, 2 router tables, a dovetail machine, a thickness sander, a planer, a jointer, a bandsaw, a digital shaper, a paint shop, from the top of my head.

As for staff, 4 owners, 2 foreman, one dept head, 8 staff.

They are doing awesome, but at a heck of a mental well-being cost from the top, down to the bottom. I don't think it has to be this way.

BTW thanks to all of you, again, for getting my gears going, again :)

From contributor Me

Cabinetmaker--I wish the whole world was like that :)

From contributor Me

And yes I am writing a proposal up where everyone wins. This is amazing. I don't think I could even find this type of professional advice outside this forum if I had the money to pay for it.

From contributor Pa

The apologies and happy face stuff does not deal with the real problems.

It sounds to me that if morale is that bad production is equally bad, as they go hand in hand with each other. IOW morale = production.

The basics are missing. First of all if it is unclear who does what, that is the first problem that has to be addressed. This is E-myth type stuff. Everyone has to have a hat/job. Trouble begins when the finisher does sawyer work or the salesman does cabinet work. The basic problem of management is to simply get the worker to do the job he is being paid to do. If this sounds obvious that is because it is, except to the guy who is up to his ass in alligators who was supposed to drain the swamp.

The key to this is training the worker to do whatever his job is. In smaller operation this is usually nothing more than showing the worker what to do have them watch you do it and then have them do it. I think in Canada they have better training programs than in the US right? This is especially hard if the worker doesn't speak the language so then you are stuck with the above method of training. E.G. Mimi's restaurant will run a waitor/waitress through 2 weeks full time of offsite training yet the cooks are trained in the method described above. In all honesty if the jobs are limited to a highly repetitive tasks this works fine, but not so on other jobs.

Then as I mentioned somewhere before if you want to manage it you have to measure it. So the production has to be given a quota of what has to be done per day or week.

This alone should increase production and point to where the problems are and improve morale and willingness. This should be done before any Lean type stuff or proposals for a new way.

After this I would look at getting policies written down or dusted off and understood by all. This way all are on the same page and working in the same direction. This is not your usual vacation, payday, sick day type stuff. This is everything that has been found to work for your company in the past everything from soup to nuts. What advertising works best, whether it is best to work 4 10hr days or 5 8 hr days, what vendor delivers the best value, whether it is best to cross cut and rip or vice versa, what sequence works best, whether a quota should be set for the shop or for individual departments, etc.

From contributor Me

Okay Pat, yes, this. On a bad day I feel like that. On a good day I think hey, company culture, happy shit, good stuff, step at a time.

But in having people be that happy, they have been talking up a storm on breaks, and I think I may have figured out a very key problem.

Everything is going good enough except for production. Which is our business. So it's a colossal problem. This is why I'm up at this hour thinking about this things and asking questions.

So owners that are also sales, are miserable because they cannot predict an accurate lead time. And they can't even get an accurate revision on lead time. If you can;t predict your lead time most often you are having to many contingencies. I know that they are in production--I see these damn contingencies everyday.

And everyone knows what they are. But there is a beleif that "the owner does not want to spend money. On anything. Ever. So we just have to do everything we use to do at a faster pace, now that we got bigger".

Now that I have sat down with this owner I simply do not beleive that this is true. I'm convinced that he meant "I want to expand using my current resources as best as possible". There is a difference between "Buy me, buy me please" and "this expenditure will cost this, but yeild this".

This is where I am left wondering if I should just get in there and not catfoot. Because this is something I can sure as heck figure out. Perhaps not as fast and well as you folks, but at least better than what is already in place.

From contributor Js

It is an interesting forum, my take is your just wasting your time and energy. You would be miles ahead finding a company that suits your expectations.

Any change you accomplish will be slow and drawn out. You are obviously going to step on some toes and annoy some employees and probably some owners if there is 4 of them. These people will make it miserable for you every chance they get. You will eventually hate going to work and will go else where.

Sorry for the doom and gloom, I have just seen the working of these types of situations for over 30 years. You are basically in a no win situatuton.

From contributor Pa

"they have been talking up a storm on breaks"

That is a indicator of morale, that is a good sign. I used to look at guys at break time as a barometer of morale . The opposite is everyone sitting by themselves or worse yet sitting in their cars. BTW if they are sitting in their cars that is an bad indicator of something else as well.

"I think I may have figured out a very key problem." is that "Everything is going good enough except for production. Which is our business"

Ok, but that is far from finding the problem. The solution to the problem will also present the solution. If not it is NOT the problem. If you say the problem is production, that does not present a solution.

An elementary use of logic is to simply ask "how come" E.G. Question: How come production is unpredictable? Answer: because we don't measure our times. As is often the case the question is the answer.

However it may take asking how come 5 or 10 times. The Lean dogma says 5 times, I say as many times as it takes to get to the real problem.

It might be: because we don't have the equipment. How come? because the owner is too cheap. How come because the owner does not know what is going on and sees it as a bad investment. How come? Because he does not know the metrics of the production. How come because the foreman is not tracking and supplying the numbers for the metrics. How come? because the owner never asked for them. How come? because the owner never does a comparison of estimates or sales price to cost. (BTW material costs are almost always good but labor can vary wildely) How Come? because the owner is good at sales but does not know anything about running a shop.

So would giving the owner some basic education on shop metrics produced a solution?

Or the owner may assume he knows everything, in which case...

But that does not appear to be the case?

I'm not saying this is the case just how this exercise might go.

From contributor La

Two kinds of "lead time." The customer's, typically waiting 'til the last minute to make decisions or changes and production that includes your suppliers and your shop. What sales people never seem to be able to understand, is that unlike sales where you can sell hundreds in a short time frame, physical constraints of manufacturing puts a limit on output. That limit translates into time, Lead time. There are things within a shop that can reduce lead times that are purely organizational (Read The Goal.) If the organizational has be optimized, that leaves you with the physical, man power, equipment and space. To change any of those takes time, $ and serious thinking about where next.

I've struggled with all of them. You will lose some customers because they are just incapable of understanding the limits. You will lose some employees because they are unwilling to change, $ is always an issue because business is much like gambling. Who is at risk? Many employees can see at least some of the problems and a narrow idea of the fix. Management will have a different view. If you can hatch a plan that makes sense to both you win. Lose the confidence of either ..... To keep the confidence requires showing progress in large enough increments that everyone can see there really is a light at the end.

Multiple steps can be taken simultaneously by different ares. Management can develop a scheduling system based on real #'s from tracking jobs. Do you use shop floor terminals for employees log in by job and function? At the end of each job, do you match the bid against production information? Absolutely required! Do you evaluate the shop production drawings to determine if there would have been a simpler, faster way to make it. (hint, don't be afraid of getting red lined by the decorator or architect, they may not know or care about construction details, just the end result.) By standardizing production details much time can be saved.

After you'd cleaned house & all the wasted space has been reclaimed do an evaluation of the shop flow. Can you get 80% of the parts/processes to travel the same route, no back tracking. This requires the office to put things out in logical order. It probably requires rearranging most things physically and paying very careful attention to material flow/handling. I'm convinced that full sheets should be handled via vacuum lifts with the lift having access to multiple units and serving multiple machines. After being cut the panels should be sorted by next operations as part of the off loading. Then transported via roller conveyor & transfer cars to their next operation. If a stack sits for more than an hour you have a problem. Reduce batch size! Figure out how to reduce the # of processes.

Sorry about taking too much space here. Small shops often have preconceived notions about crafty things. That's fine but it's not business.

From contributor Ti

Have you considered pointing your bosses to this thread?

From contributor Pa

This situation reminds me of something that happened to me a year ago. I got an email from a young lady who had been working for a local craftsman for a couple of years. Typical small shop: no organization, no marketing, didn't use email, production always out of control, broken machines that didn't get fixed. She came by and we had lunch. For an hour we talked about ways that the operation could be improved. Then I asked her two questions:

1) Why are you here talking to me and not your boss?

2) If you kill yourself, take on all of these problems, and save the situation, what do you get? Are you being offered a bonus, or stock, or a raise?

She was visibly embarrassed after question number one. She'd tried to get him to come along, he said he was too busy. Too busy to spend an hour that might help him? Yup, just didn't want any advice. As for number two, no promises whatsoever - she was doing it because she was concerned that the shop was going to fail and she was going to lose her $15 an hour job.

Mel, it sounds like your company has one advantage over that shop: you have more work than you can handle. On the other hand, you're gearing up for a couple of years of incredibly hard and frustrating work. And now that you've told us a little more about the shop, I see red flags:

1. FOUR owners? Is one of them a majority owner? If not, who is in charge? How do they divide up the financial commitment that a growing shop will require? What is their goal for the operation? Are they making the money they want? Do they all want to grow?

2. When the owner is busy making sales, the business cannot grow in an orderly manner. I know that for a fact, I was in that situation for more than 25 years. It's only when I stepped away from an operational role that I was able to find time to start guiding the company forward. That means that I no longer have something to do every minute of the day - which can be uncomfortable. But it's necessary that I steer the ship and let others do the work.

3. On the face of it, the ratio of office to shop floor guys seems high, but that may not be a problem if you are doing a lot of outsourcing.

I'm lining up with Jso at this point: you are most likely wasting your time. You sound like a dream employee to me: someone with both skills and initiative. This industry is starving for people like that. Other industries provide better opportunities, so we don't see so many self starters. The average woodworker is happiest doing something that they already know how to do, not thinking of better ways to get ahead.

You owe it to yourself and your family to make sure that your efforts and skills get the compensation you deserve. If you are going to devote yourself to fixing this company, make sure that you will be rewarded. Define success with the owners, and when you get there make sure you are getting a piece of it. Otherwise you are going to kill yourself for their benefit.

From contributor Me

Man can you folks get my gears going. So if I start condensing questions being asked and concerns being put forward, I beleive that I can group them as such:

-are you wasting your time?

For sure no. A thing that I forgot to mention in all this techincal business talk--I like these people. Quirks, faults, and all.

-will this stress impact my family? No. I'm totally spun, no matter what. Having something to grind my mind on that is outside of the family has proven to be healthy for me. My marriage is tight as a rock, my kid is happy, my inlaws (that do daytime childcarecare and live in our ground floor) love us and we have great times and dinners every day.

-will you be compensated? I have been wealthy, broke, stranded. I don't care anymore. I'm always fine. I'm in it because I want to take a big bite out of life, eat with two hands, and really like to work with wood for some inexplicable reason. I have my realestate investments, I don't care what I make at work. No one gets rich working for someone else. But I love working for someone else. This is brain food and community at the belly. I do it because I love it, no matter what it throws at me, no matter if I'm sometimes exasperated at problems that have easy fixes but are still problems.

-are they ready for lean? Hells no. They need to learn how to talk to each other, cooperate, tackle growth with mind and not aggression. This is a learned skill and I will have more fun showing them how to do it than taking it into overdrive so I can admire my brain child.

I can do this. For sure. But as you all hint at, slow down, young grasshopper. Pat--you are right. Production problems are a symptom, not a source issue. The issue that needs taming right now is aggression. And that's a beast I know well and can handle. Look at lean as a group philosophy when they are sturdier on their feet.

BTW--small success today. We are going to tackle the pile of bent lumber. We brain stormed about how to do it, and we are on board to grind at it. And still lots of happy floating around. I feel it. Cooperation is starting and it's already yeilding results.

Thanks for the break pedal--I think sometimes all I have is a gas pedal :)

From contributor Me

Tim, sometimes I have momments where I wonder if they've seen it. And wonder in how much shit I would be if they had. But that's okay really, I have nothing to hide. I'm a huge fan of open discourse. Honnesty yeilds advice you can actually use.

Maybe one day!

From contributor Da

"4 middle managers for 8 production workers"

That is totally incomprehensible to me. Granted, as one poster pointed out, you may need more if you do a lot of outsourcing, but still!!

We have 8 production workers and NO (non-productive) middle managers. We have three departments, and each "department head" (kind of a stretch to call them that, really) is a hands-on productive worker. Our milling shop foreman MAY spend 5% of his time doing non-productive work.

I (the GM) do have one mostly "non-productive" assistant that works on scheduling/quoting/work-order related stuff, but he also does all our IT work as well as a lot of the equipment maintenance.

Sounds to me like it's way past time to cut some fat.

From contributor Me

I've heard in school of manager/worker ratio but of course information like that sounds "but of course, who would do that wrong" till you actually see a misuse in person.

The one thing academia never touched on is the strange social turf wars that arise from the classic, to many cheifs, not enoughs indians, scenario. (just using the expression because it's really good--no desire to be polititcally incorrect or sound like a prick in any way)

From contributor Pa

A lot of it depends on how repetitive the work is.

I don't think anyone can effectively manage more that 8 people if the work is custom enough maybe not more than 3?

I think there can be a tendency to be penny wise and pound foolish on this point. It is about a concept called comparative advantage, it is at the root of the entire world economy but also at the root of a small company.

A owner can try and do everything himself or he can hire a secretary to do some of the tasks. If 25% of the owner's day can be freed up to do something else, would he recoup the expense of hiring a secretary?

One of the hardest things to do in a small shop is be in charge of production and sales as it is similiar to going down the freeway and putting the transmission into reverse. As production is about getting stuff out the door and sales is about getting stuff in the door. Two different directions.

Hiring a foreman is the same type deal as hiring a salesman.

Either way you have to look at the numbers and see if it the cost is recouped or not. Generally speaking you are better off using the idea of comparative advantage.

There are also costs that are not often realized. Such as the cost of going below your break even point just one month as then your net for the year will be 8% less than it would have been. Or depreciation costs of high tech equipment. Or the cost of training someone. Or the cost of quality control and the cost of losing a customer. IOW there are lot of functions/costs that go into creating a business that can drain a business that are not really accounted for let alone assigned to an individual.

From contributor Me

"I think there can be a tendency to be penny wise and pound foolish on this point."

I was going to say you really have a way with words. But it would probably be more accurate to say that you really have a way with thoughts.

I was thinking about this. Does it have a lot to do with controle? I find people hide behind tons of excuses when it comes to letting go of mundane tasks. I repeatedly see managers and owners stretch themselves thin just to keep power over the little things.

I think we call it micromanaging? I don't know.

But I'm not perfect, I do it too sometimes. Stupid example, perhaps--- my inlaws live with us. 4 adults in one house. Everyone knows how to cook. But I worked in the kitchen of an italian restaurant in Old Quebec when I was younger, and can cook up one mean storm. From artisan bread, to beer from grain, to filet mignon with a wine reduction.

It probably took me a year to share the task of cooking for a feast. Now I see the power in it. The result is faster, more efficient, sometimes a bit of a beautiful surprise, and way more fun as the 4 of us rocked it. Does it matter that the vinaigrette is slightly lacking sweetness?? Who would ever care except me. And even then.

Law of diminishing returns--too much of yourself can be that single increase that drives everything else down by keeping it all constant.

From contributor Pa

Make no mistake about it woodworking is a tough business, i.e. competitive, there is not much room for anything or anyone who does not create exchange. Exchange is the key, you hear it over and over, always give them a little more than they paid for.

I'm just saying that there are other things that have to be done that are not directly related to production of the actual product. There is the shop and all of the work involved with setting it up then there is the woodwork itself and then there is the maintenance and repair of the shop and the repair and quality control of the actual woodwork.

If the shop cuts costs on the latter two it will come back to haunt them. I see it all the time when a restaurant gets sold the new owners get the idea they can cut corners on the ingredients or service and the people won't notice. Except the customers do notice and before they know it they are gone.

IOW the lack of quality control does in most companies sooner or later.

As to why they don't change I think it is because when a company finds something that works they are reluctant to change, "if it ain't broke". And when you start trying new things, things get unpredictable in a hurry, and prediction is the friend of a business and the lack of prediction the enemy.

There is also this story that IMO has something to do with the situation:

In a laboratory somewhere near Omaha, some scientists placed three monkeys in a room. In the center of the room they placed a short staircase. At the top, the scientists hung a bunch of bananas from the ceiling.

Whenever a monkey tried to climb the stairs to get the bananas, the scientists sprayed the other two with a fire hose, much to their dislike. After many repeated dousings, the monkeys took to beating the monkey that tried to climb the stairs. Eventually, the monkeys stopped trying to get the bananas, and the scientists put away the hose.

After a while the scientists replaced one of the monkeys with a new one. The original two monkeys violently protested any attempts by the newcomer to climb the stairs, and she quickly quit trying. One by one, the scientists replaced the other two monkeys, leaving no original participants.

As new monkeys were introduced, they in turn were beaten and learned the rules. Although they had never been sprayed or even seen the hose, the monkeys continued beating each other for climbing the stairs.

Why? Because that's the way they'd always done things.

From contributor Me

Man alive, are poeple ever afraid of change. I will never understand it personally. Boredom is my demon, and change is fun for me. But yes, for sure, the monkey beatings are there as ever.

As a psych student, you hear over and over again about these sorts of experiments. The pigion that gets fed at random intervals, but starts studying what he's doing when the food comes out. Repeats the behavior over and over agian. Even if it does not generate food. But if he exhibits the behavior, and at some point more of the random interval food comes out, big win. Behavior gets reinforced. Somehow stronger than if the behavior always yeilded food. Sometimes is somehow more powerful than all the time.

This is some powerful stuff. It's behind gambling and others--the deep dark stuff behind chasing the dragon.

It's a nasty stumbling block to progress--personal, social and professional. Still not all that sure what to do with it besides tackle it with the most patience I can muster.

From contributor Me

Wait a sec... Pat, you own your shop, right? And you know this human gut stuff.... How do you deal with it? Call the shot and say tough luck, or actually human manage it?

From contributor Pa

"Call the shot and say tough luck, or actually human manage it?"

What?

IMO you manage by the numbers, the survival of the company will suffer if you don't.

From contributor Me

Surely there some potatoes with that meat, no?

From contributor Da

"I don't think anyone can effectively manage more that 8 people if the work is custom enough maybe not more than 3?"

Without analyzing the numbers, you may well be right.

Maybe I'm not understanding the situation either. The term "middle" manager, to me, implies that there are both higher and lower managers as well. These "lower" managers I think we would call supervisors or foremen depending on the situation. So in context, I would say that a "lower" manager, who is directly managing the production, should be able to supervise 3-8 people and still be mostly productive themselves.

Using this same ratio, 4 "middle" managers should be able to collectively manage 12-32 production workers. Ok, I am the owner, so I am Upper management. But I also wear the middle hat because we just aren't big enough to justify a second position IMO (and I'm the boss, so my opinion is the only one that counts :-) ).

I have had the combination of fortunate (vacation), planned (business trip) and unfortunate (health issues) events that kept me away from the office a total of 9 weeks from September through the end of January. The periods ranged from 1-4 weeks each. Yes, I was in touch by phone and email, but I was not needed for the day to day stuff. My supervisors and sales staff have the knowledge and authority to do what needs to be done. In fact, we had an all time record month during that time.

From contributor Pa

David

OTOH if a manager is so involved with getting the work done that he is not exterior to the workers can you say he is a manager?

Most woodworking companies are very thin on management in order to stay competitive.

Being exterior to the fray is a necessary element to a business. Albeit may only be the owner. If you stayed away from your business indefinitely it would eventually dissolve. For sure I see guys like Paul Akers who spends more time away from his business or "working on his business" than "working in his business" but none the less IMO there has to be someone to give it direction and truthfully that person may not be the best manager e.g. Steve Jobs was good at the former and not at the latter. But without him you would not have an Apple.Wozniak was good at the prior but apparently not at the latter but Apple probably would have come into being without him.

If a company allows quality control to be handled by the customer they are in trouble, quality control IMO requires an exterior point of view to the guy who is actually doing the work.

Scheduling is another one of these things maybe not enough for a full timer person maybe enough for a few full timers.

If the guy who does the purchasing is busy with other tasks will he get the best value or will get the easiest purchase. Why not just buy a years supply of whatever and be done with it? Or would he pay for himself and then some by taking the time to shop around?

If there is no shop foreman then no one is particularly intending to drive work out of the shop. In which case the owner is a whip saw between driving work out of the shop and driving work into the shop. This situation will not last for long.

How much production is lost or money left on the table by not performing these non productive tasks?

What do you actually make? By the way you talk it seems different than panel processing?

From contributor Da

"OTOH if a manager is so involved with getting the work done that he is not exterior to the workers can you say he is a manager?"

Not really. That is why I was trying to clarify what a "middle manager" is. To me, that would be a totally non-productive worker. And to have 4 of them for 8 productive workers seems way beyond overkill to me.

"If a company allows quality control to be handled by the customer they are in trouble, quality control IMO requires an exterior point of view to the guy who is actually doing the work."

Absolutely. While there do have to be controls within production, too. However, we are not big enough to have a QC-only position. We have three departments, and each subsequent department in the flow QCs the previous one. In the final department the packager is responsible for QC. Sometimes work is also being done in that final department, in which case a different person packages than does the work. This way QC is done by someone other than the one doing the work.

"If there is no shop foreman then no one is particularly intending to drive work out of the shop. In which case the owner is a whip saw between driving work out of the shop and driving work into the shop. This situation will not last for long."

Unless it's a 1-2 man shop, I agree you need a shop foreman. For about 20 years I had a business partner, and he was the production manager and shop foreman. He spent less than half his time on the floor. The best thing that ever happened to production was when he left and I had to put an actual shop foreman in place. He's on the floor 95% of the time and knows what's going on all the time.

No, we do not do any panel processing. We use only solid wood, and produce "moulding". Mostly picture frame moulding and wide plank flooring.

From contributor Pa

Sometimes-Often I think that the sole criteria of a business should be how well can it control it's processes.

Custom Cabinets for fickle homeowners who are neurotic- not so much

Custom Cabinets for GCs who pay if the mood strikes them and can borrow from Peter to pay Paul-not so much

Molding that is run according to an approved sample with fewer variables-much better

Moral to the story? narrow your offerings to gain as much control over the processes as possible. But you have to be good enough at marketing to work in that specialty and have enough work to for it to be worth it. And when the market changes to have the good sense to do something else.

From contributor Ti

Pat,

Two things to bear in mind about any mature industry is that all the low hanging fruit has already been harvested and everybody else is in the same soup you are.

What this means is that every opportunity to be innovative resides under a rock or other hard-to-harvest place and that the pipeline includes enough money to pay for the production PLUS the inefficiency. All you have to do is mine the inefficiency.

We don't set our own prices, our competition sets this for us. If they insist on touching 2 out of every 5 dollars with a blow torch all you have to do is put away the blow torch and you have an extra $2 to work with.

For the custom, fickle, world you need to focus on how to guide the client process. Get in front of all the questions in a way that is comprehensible to the client and only work with allowable answers. Frame the client questions in a way that the answers become triggers to minimize non-value added management.

Crown molding is a great example for this. Most moulding catalogs describe their product offering in terms of what the moulder operator needs to know. A 3 3/4 cove molding tells the millwork department they need to factor in a 4 inch blank when estimating material costs.

This does absolutely nothing for the customer who needs to know how tall the crown molding is or how far it projects from the wall. How many times have you had to call the millwork company to ask that question and how confident are you in the answer they give you over the phone? Somebody on their end also has to trot out to the warehouse, find the molding and measure it for free. None of these activities add any value but all of them are fraught with expense and potential costs of mopping up miscommunication. This seems to be really low hanging fruit yet remains unharvested.

Just because you build a really custom one of a kind piece doesn't mean you have to use ad hoc communication systems.

From contributor Da

"Molding that is run according to an approved sample with fewer variables-much better"

FYI, we have very fickle customers as well. We have also dealt with customers who pay if and when they feel like it; which has at times been "never". And making _quality_ moulding is not as simple as merely running a stick through a moulder, sander and finishing line.

The grass is always greener... just sayin'

From contributor Pa

Tim I will disagree.

Yes you have to have a system. But the number of variables grows exponentially

as you add "custom" to the mix.

David

The proof of the pudding is in the eating, companies that run molding more often than not are successful. Sort of like electrical contractors, very few go belly up. Cabinet shops, 11 out of 10 fail...

Why? IMO it all boils down to control, no control = no profit.

From contributor La

Pat, you left us off your list of easily controlled... Store fixtures. What could be easier? Just make what the designer dreamed, make changes on the fly, deliver in fifteen minutes and get paid in several months. Takes a special kind of fool to be in this business!

Tim: Communications is key BUT how do you know the other end is interpreting it the same way? What are their vocabulary skills? Material knowledge? What are they picturing when they say they want "natural cherry finish?" They call the day it is supposed to ship and tell you they can't take the semi load that is blocking your dock until two months from now. They just discovered the concrete for the floor hasn't been poured. Or as recently happened, the roofing hadn't been completed and all the fixtures got drenched that had just been delivered, on time. Need replacements next week. "The mall's insurance company will pay for the fix." Maybe!

From contributor Da

"companies that run molding more often than not are successful. Sort of like electrical contractors, very few go belly up. Cabinet shops, 11 out of 10 fail..."

Effect does not equal cause.

Let me suggest another reason. And I mean absolutely no disrespect to people that start out in their garage/basement with hand-me-down contractors equipment. In fact I had personal interaction with just one such person who sold their company for over a Billion dollars.

As implied above, it's possible to create spectacular cabinets with a very small investment. But what goes along with that is that it's tempting for someone to say "Hey, I can do that." and start a "business" that hasn't really been thought out. Ergo, fail.

It's pretty hard to start a moulding company on a shoe string. Not impossible, but pretty hard. That means that in order to get a couple hundred grand from a bank you've got to show you've thought it out. Maybe even go through making a business plan. And the bank won't give you the money unless they think you'll be able to repay it. Ergo, success.

Granted, neither scenario is a rule, but I'd bet it happens more often that way than the other way around.

From contributor Pa

Pat, you left us off your list of easily controlled... Store fixtures. What could be easier? Just make what the designer dreamed, make changes on the fly, deliver in fifteen minutes and get paid in several months. Takes a special kind of fool to be in this business!

Literally a LOL, a special kind of fool is about right.

"They call the day it is supposed to ship and tell you they can't take the semi load that is blocking your dock until two months from now. They just discovered the concrete for the floor hasn't been poured. Or as recently happened, the roofing hadn't been completed and all the fixtures got drenched that had just been delivered, on time. Need replacements next week. "The mall's insurance company will pay for the fix." Maybe! - "

Or you can't get a truck going east because of the special longshoreman strike. So you settle for a truck with tarps the. the guy shows up and I'm informed by one of the workers that the guy is obviously a tweeker. So you load and tarp the truck for the less than useless driver. He makes it as far as Oklahoma before he runs out meth and takes a nap for a few days (about 4) you get another driver to take the load the rest of the way by which time the customer has missed his grand opening.

Or the warehousing company informs you that your product is damaged because of because of improper crating, which had holes in one side and out the other side of the crate that look suspiciously like forks from a forklift.

Or you pay a premium fee to ship the fixtures by a house mover who then decides that since the store is not ready that he will leave the fixtures in a warehouse who manage to turn 100k in fixtures into 50 dollars in waste material.

Or that your electrical doesn't comply with Illinois electrical codes even though they fly with every other state.

Yea I see your point, compared to herding cats this is easy.

From contributor Pa

"Effect does not equal cause. "

Yup or correlation does not indicate cause. But it is a damn good place to start looking.

"It's pretty hard to start a moulding company on a shoe string. Not impossible, but pretty hard. That means that in order to get a couple hundred grand from a bank you've got to show you've thought it out. Maybe even go through making a business plan. And the bank won't give you the money unless they think you'll be able to repay it. Ergo, success. "

I'm not talking about garage shops.

From contributor Da

"I'm not talking about garage shops."

And I'm not trying to say that "we" have just as hard a job as "you" (whatever that means).

But how many people started a cabinet shop on a shoe string, were paying the bills and making some money, and took the next step before they were ready for it?

Bottom line, this is a capitalistic society (for the most part). If someone thinks they can make money in a cabinet shop and it doesn't work out, that's the way it goes. Who knows why? Using your terms, 11 different reasons for 10 different shops.

Until the same person starts both a cabinet shop and a moulding shop under the same circumstances (an impossibility IMO) it's pretty hard to make a determination as to which one is easier to make profitable. Maybe people that start cabinet shops are more craft oriented, and not so good at business. Maybe who knows?

BTW, the guy that sold his business for a Billion came to the US and tried to repeat. He failed. Pretty miserably. At least he could afford to...

From contributor Pa

David I'm not criticizing you, quite the opposite, I'm criticizing the idiot looking at me in the mirror.

Again I think the ability to control your processes is most important.

BTW quite a few guys on this forum do both molding and cabinet work. I don't really here them complain about losing control on the running of the molding.

You are right it is a free market. I think that we should spend more time looking at what is a good business and what is not.

Who was the billionaire cabinetmaker? I mean there can't be more than a half dozen of those on this forum.

From contributor Da

Pat - funny how a Google search can turn up things you never knew.

It appears that I may have gotten one of those "telephone" stories - you know, where by the time it gets passed from one person to another a dozen times it's totally changed. Well, not totally changed. But Malcolm Healey only netted 200MM Pounds, or less than half a Billion $US for the sale of Hygena (in '87). And while he did start his business in his father's garage, it wasn't Hygena. And apparently Mill's Pride (the project I was involved in) wasn't as big a flop as it appeared last I knew.

The internet is amazing :-)

BTW, I seriously doubt you're looking at an idiot in the mirror. And frankly, I didn't purposefully choose this course of business. We just allowed ourselves to be pushed the way our customers wanted. The only thing we really took control of was deciding to not do furniture any more, as it was a disruption to our moulding, which was becoming our bread and butter.

From contributor Me

David, the most successful people I know kind of "fell" into their business. I think it's because of their adaptibilty/responsivity to the market. No child says "When I grow up, I want to produce robertson screw bits". But the guy that did sure did well.

Identifying what works and sticking to it... K.I.S.S. is simple but not always common.

From contributor Jo

Oh how I enjoy this thread.

The Lean Journey is just that, a journey. Make no mistake, not everybody likes a road trip.

So, let the first of the 5 Why's be this:

If there is a more efficient (cost effective, faster, higher quality) way, why on Earth would a GM have to make friends with the folks on the floor who do it any other way?

Management of labor (even in quantities greater than 8) requires a singular focus - the bottom line. You are not paid to make friends, cabinets, or picture frames. You are paid to make your owners ( 4 or 1,000,000 shareholders) more money.

Sometimes marriage counseling ends in divorce and, sometimes Kaizen ends in cultural genocide. My favorite answer to, "Why do we do it this way?" Is- "Because that how we always have done it."

Ever heard of an electric car?

Somebody asked WHY?

So, do not yield to the shop bully. Be the GM. STANDARDIZE the work. Custom jobs are different sizes, colors and/or materials. They all get drawn, planned, cut, glued back together, finished, and out the back door.

Process map each value stream in it's current state. Assign costs to each step, touch, and set-up. Then, cut the fat. Reduce set-up times. Reduce in-house walking. (Put a pedometer on each employee for a week. That will terrify you. )

Then start cutting the fat. Lean it out. You'll see reduced lead time, reduced re-work, increased through put.

And please- start a Red Tag program. Find everything on the floor that has dust on it. Put a red tag on it and if possible, move it to a holding area. When the date on a Red Tag exceeds your pre-determined holding period; pitch it. Jigs for Apple II computer shelves do you no good.

Measure time in seconds.

Remove all non-value added activities.

You are doing the right stuff, asking the right questions. You are on YOUR Lean journey. It will not likely end with the firm who currently signs your check.

But 5 copies of "The Goal". Read one and give the other 4 to your owners. Then invite them to share a pizza and discuss the book and how it relates to all of you.

It will be the best toll you past on your road trip.

Good luck, happy trails.

From contributor Me

John, you got me thinking. And rereading the thread. Are we having a man vs machine debate here? I think so, and I'm happy about it. Because I really don't have an answer to this one.

I've worked for someone like you before. It was oodles of brainy noodles, and it was good plain fun. A place where, if you can show, in a clear and rational manner, what isn't working, what it's costing, what to do about it, how much that will cost, and can answer any questions about what was not in the report, you get what you want. Thing of beauty. Lay the hammer down, get it done, see it fly.

But this current endeavor has its merits too. Not to get too nerdy on you, but some interesting stuff from cognitive neuroscience... Aggression and fear is housed in the reptilian brain, that base structure that we share with all other animals. Its where the 4 Fs are processed--fight, flight, feeding and sexual reproduction.

When these 4 Fs are activated there is a disconect with your higher cognitive functions, namely the frontal + prefrontal cortex, that take care of things like planning and multitasking.

Liberating people from bathing in their reptilian brain, to see what they do when they access their thinking brain, is an amazing experience, and even straight up entertaining. I have 3 years to kill, and it's not a bad way to do it.

So as in any debate with extremes, the answer usually lies in the middle. I'm guessing getting hardcore lean in a big operation, a pre-planned, well oiled machine, will generate happy enough employees that just get a job well done and go home.

But maybe this is a question of scale? What if you have a small/medium shop, that isn't yet ready for the Big Machine of lean? I think there may be some human work to be done there.

But all that said, this is just a bunch of musings. I have no idea what the answer is. I just know that these efforts feel good, and that's more than what the Big Machine of industrial world wide manufacturing ever provided for me.

Gosh, I seem to get stranger and stranger as I get older.

I'm ordering the Goal--too many of you have insisted on it to ignore it. You guys are awesome with your homework :)

From contributor La

I just checked on half.com The Goal 2004 revised ed. about $3 "good" condition + $3.95 shipping. Well worth its price!

From contributor Pa

Also I suggest subscribing to Paul Akers site. His weekly videos are great and put a very interesting face on Lean.

He answers most questions right away. His mission is to turn people on to Lean.

Some though are about his endless vacations, which might say something about Lean?

From contributor La

OK, Pat, I subscribed. He has been extremely successful. This weeks video was his trip diving in the Indian ocean. Brought back great memories of diving in the PI. The tropical waters team with all sorts of life. Not so sure about getting up close and personal with a Moray eel!

From contributor Pa

Damn, I asked Paul to not allow you to subscribe, because you are not a true believer.

Yea he has some fluff in there but he has some interesting ideas on Lean that really show how he applies it.

Truth is I think his real wealth comes from investing in rentals. But that does not make less of his Lean successes.

BTW the one thing he does not do anymore is have a cabinet shop. Maybe that says something as well?

From contributor Pa

BTW Morays are the opposite of politicians. They are not dangerous when their mouths are open.

Dangit there is the P word again.

From contributor J.

You see Mel, Lean has nothing at all to do with efficiency.........it is all about balance.

You could, for example, carry several extra canteens with you when you are hiking in the forest. This way you could be really efficient when you replenish your drinking water from the creek.

This efficiency, however, comes at great cost. You could have been carrying whiskey in one of those canteens.

It might make sense to gather a little extra firewood, however, so it can kind of dry out a little bit overnight. This could be considered buffer.

I know that some of the Lean guys here will advocate for the powdered alcohol but some things don't need improvement.

From contributor Me

Pat and Larry, done and done! (Pat that link-- when I saw the scubba diving title I wondered for two seconds if you had been hitting the bottle lol )

J Walker-- so I got given a bunch of homework from the folks here and ordered a bunch of books. Started with the Toyota way (not done yet) and realised that my APICS course and LEAN is not the exactly the same as Toyota philosophy. In fact, the lean manufacturer that i worked for has a lot of cross-over with early ford style mass manufacturing when it comes to human resources.

It's comforting to know that someone is winning by treating their humans like a resource, and not just some big obligatory PIA.

Thanks again for the homework folks--looks like my questions really aren't new. Which is a good thing!

From contributor Ti

Mel,

That you should find your APICS course is not exactly the same as The Toyota Way is not surprising. As Jeffrey Liker himself points out in the beginning of that book "The problem is that companies have mistaken a particular set of lean tools for deep "lean thinking".

The concept of "Lean" thinking is almost like a cult these days. You can't just distill it down to a few buzz words. It really is more than a soundbite.

The Harvard Business Review's Archives has an article called "Decoding The DNA of Toyota". It's a fairly terse read but it gets the job done in about ten pages.

From contributor Me

Tim, I was just thinking about how tons of people tried to apply "lean thinking" but really only went with waste reduction/efficiency.

So--if the principle of Toyota revolves around freeing worker's thinking brains and watching it fly, I'm thinking that their systems are very organic. Which leads me to wonder if one really can just copy/paste the systems in their own place and watch it go. Well obviously not, according to past recorded failures mentionned in the book.

I think what the Likers is saying page after page, is that it's a philosophy, not a recipe. Yet somehow a bunch of people walk away with a recipe--acacemic circles included.

From contributor Ti

Mel,

It's been a while since I have read Liker's book. There's a particular chapter that I think about periodically that talks about using computers to process work orders and white boards to pass out tasks.