Engraving Aluminum in a CNC Router

Compared to machining wood, working with aluminum calls for different tooling, speeds, and cooling methods. July 29, 2012

Question

I have been using a CNC router for woodworking and engraving relief on wood and MDF for 2 years, without any trouble. Recently I purchased a new router to engrave in aluminum, but after losing several tools, even in the roughing process - I did not get any results.

My machine has the following specifications:

4.5 KW air cooling spindle

Max RPM 18000

Mist cooling system (using kerosene as a coolant)

2500x1300x300 mm working area

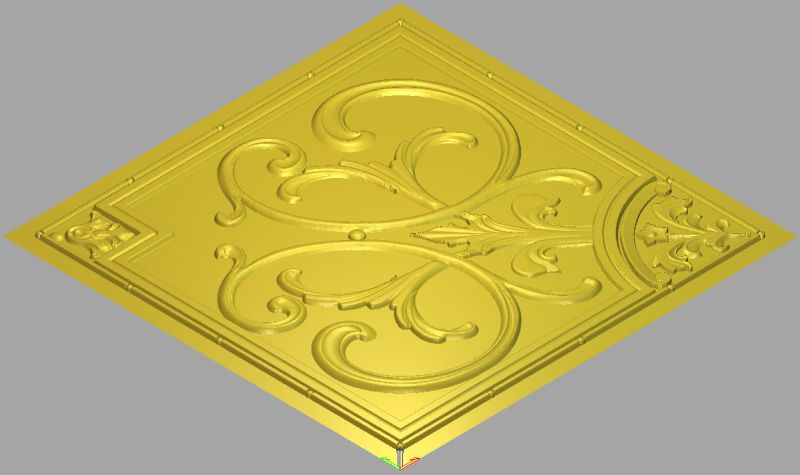

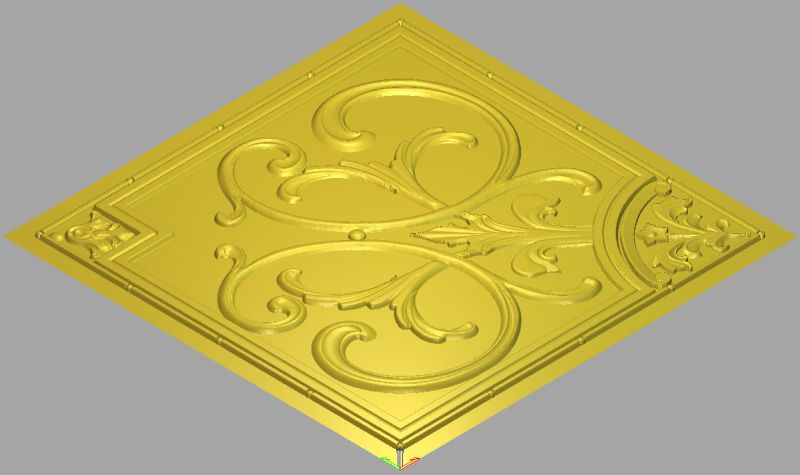

The first design I started is 600 x 600 x 6 mm in size (see picture below).

Aluminum I am using is extruded grade 6061.

The tool I am using for rouging is endmill 3mm and 3.175mm and tried 2, 3 and 4 flute tool. 9000 RPM and 18000 RPM with 0.2, 0.25 and 0.3mm deep cut with a 1.5 to 3mm stepover and 600 to 2000 mm/min feed rate, in combination with above all. But after a while the tool gets broken and the chips are melted inside the flutes of the tool.

What is the right way of doing this design in aluminum in the above size?

Click here for higher quality, full size image

Forum Responses

(CNC Forum)

From contributor M:

A 3mm (1/8") cutter is way too small for roughing. Go bigger to remove majority of material. Also, I would look at an aluminum specific coolant to run in the mister. 6061 machines quite well and should not be sticking to your cutters. You need to remember a router does not have the rigidity of a metal mill, so small bits are even more fragile. Look for tapered type ball bits for your finish passes.

From contributor J:

Using "O" flute bits will help a lot. 6061 is plenty hard and not too difficult to machine. Speeds at 80-100 ipm, spindle rpms 12000 and depth at .1 or less.

From the original questioner:

Thanks very much. I will try both the options suggested - bigger tool and smaller tool with suggested IPM and RPM.

From contributor B:

For this type of work you will ball end two flute tools and get some engraving tools. They make single flute carbide bits that that can machine fairly wide areas or even the tightest areas and radii. The tool you are using is loading up because you are plunging with it and end cutting with it, whereas a ball tool would be better in multiple passes. You should be able to cut that aluminum dry (it's hard) with just a little coolant mist.

From contributor J:

If you are going to machine a lot of aluminum, a cold air gun is a good thing.