Question

I've got a quatersawn white oak kitchen to build later this month. I usually use water-base as my clear coat. I need a few suggestions on what product to use for popping the grain. I was thinking a light stain, maybe even mixing some transtint dye into Sealcoat shellac and spraying it. I also would like some colors.

Forum Responses

(Finishing Forum)

From Paul Snyder, forum technical advisor:

If you just want to bring out the natural color and figure in the wood, then a coat of shellac on the bare wood followed by your water-base finish will work fine. An alternative is to use a coat of oil-base varnish in place of the shellac, let it dry overnight and then topcoat. If you want to add some color to the wood, a dye/seal/glaze/topcoat finish works very nicely on quartersawn oak.

Dyes (especially water-born dyes) often leave the pores looking white.

The glaze colors the pores and adds contrast to the dye color which makes the rays and flecks "pop" even more than the dye alone.

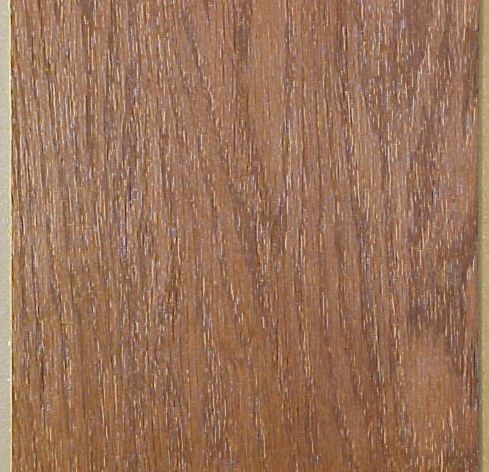

No matter what solvent they're reduced in, dyes leave the pores looking white often enough that I always use a stain or glaze over the dye when I'm working with oak. I don't like the look of the white pores myself. Dye alone can look like this sample:

To color the pores, I use a pigmented stain or glaze over the dye. Either way, I choose a color for the dye that will add highlights to the wood that complements and/or contrasts the stain/glaze color. Here's a quartersawn white oak step board that shows the effect:

The section labeled "A" is bare wood with a lacquer finish. Section "B" is dye only. Section "C" is dye and glaze. Section "D" is glaze only.

The range of color choices for both the dye and glaze/stain are unlimited. In this example, I wanted a lot of contrast with a fairly bright dye color. The glaze is a darker brown and the point was to accent the pores and make the rays and flecks really stand out. The look it achieves is worth my time.

As far as making dye color the pores, it doesn't matter how much effort you put into it. I've tried every technique that I've ever heard about; none of them work consistently. Besides, if it was a matter of "elbow grease," who has the time to put all that effort into one job when ten more are waiting? The real key is knowing why a dye is desirable in the first place, rather than just using a stain.

I can get the dye into the pores quite easily. The problem is getting the cell walls of the pores to consistently accept the color (especially on veneers). In this sample, I filled the pores with a solvent reduced dye and then watched the pores turn white and the dye bleed from random pores as the dye went through the drying stages:

This effect is more distinct with some colors than it is with others. And some oak boards will accept dyes better than others. In white oak, the problem is sometimes attributed to tylosis, but that doesn't address the issue with red oak.

Section "B" in the sample above doesn't have glaring white pores. The dye color works well with the wood and there's very little contrast with the pores (the dye is nearly the same color as the pores). Here's a cropped section of the original picture showing just the dyed section and you can see the pores more clearly: