I have a corporate job working in technology. As for cabinetry, I probably know a little more than your least skilled employee but probably not as much as the guy just above him. I have for some while had an interest in going into the cabinet business but I would not consider quitting my current job to do so.

If I found the right person, I would consider a partnership with someone who would be part owner as well as an employee of the business. I would have a hand in setting up systems, procedures, accounting, etc. I have a decent monthly surplus that could help to stem the losses of the business in the early stages. Also, I own a 12k sf industrial building that the business could use free of charge until it had some momentum and could pay a monthly rental fee.

The question is if you were considering this, how would you go about finding someone for such a venture? I would want someone who is a true entrepreneur but I fear that I would be more likely to attract someone with the mindset of an employee given that this person would accept less risk/reward by partnering. Thoughts?

From contributor Al

You would need to define the value of the rent and investment and it would need to be considered a capital contribution, then when he works there would need to be a value and if he draws less the balance is a capital contribution, basically he earns sweat equity. Then somewhere down the road you are profitable enough that you bonus each other and clear up the equity difference so its at a desired goal.

I think its going to take careful consideration to find the right person that understands for this partnership to work he needs to put in all the time it takes to make the business grow and so that he feels his contribution is as much a part of the success as the financial contribution. There is a real value to someone who can make a business into something and that value is greater than the ROI of x dollars invested. How the two of you figure out how to value where his time has value that is equal to or greater than the risk of your investment.

The better he performs, the lower your risk is. The last thing you want is to buy an employee a company with all the benefits of ownership and none of the risk or effort. He needs to understand that cash flow needs to be managed and it requires some sacrifice to make a business work, whether that's time, time away from family, reduced income, not being able to "keep up with the jones" in the short term, he need to understand that the resources you are offering are precious and they can't be squandered.

I think the interview / search process would be a fascinating endeavor and how well you are able to define your expectations and how well the partner is on the same page with different expectations of you will be the telling tale.

Will the partner ask the right questions on what are the limits of you contribution, when do you expect to see a return and what is your expertise in discrete or job shop manufacturing that will convince him you have the ability to implement systems that make the business efficient, easy to operate and sell product and help attract employees.

This is like an adventure down the Amazon, many will point out how dangerous it is and how nuts you are, you need to find the captain that can take the ship safely to the sea all the while recognizing the danger at every corner.

Come back in a few years and tell us how the journey was and start helping others.

A-

From contributor Pa

It sounds to me like you are making some assumptions that are not likely to come to fruition.

Why do you want to own a woodworking facility?

Why would it make sense to start out with 12,000 sq ft. Why wouldn't it make more sense to lease out the building and start with a smaller shop?

So you crave a hands on activity? Which perhaps you don't get from your work?

Woodworking has to be one of the lowest profit businesses going. With headwinds coming from offshore competition, automation (which makes the ante for a new venture in the $100k + range), demographics that will not show an increase in demand for housing until 2020, what will technology come up with that makes the cabinet shop irrelevant?, those same demographics and other factors make employees next to impossible to find?

The purpose of a business is to raise the customer's standard of living, i.e. this has nothing to do with making a profit.

Any business owners purpose is to make a profit.

Why not just do woodworking as a hobby?

From contributor Bl

Alan, thank you for your response. I agree that it does sound a little nuts which was part of the reason for my posting. Sometimes I get ideas and the more that I think about them the more that they make sense, and it's only when I explain them to someone else that I see the flaws in my reasoning.

Pat, thank you as well for your response. No, I do not crave hands on activity. My undergrad senior project involved a semi-custom cabinet factory, so anything that I know about cabinetry and woodworking I learned from there plus reading on Woodweb plus conversations with local shops.

As for your questions:

"It sounds to me like you are making some assumptions that are not likely to come to fruition. Why do you want to own a woodworking facility?"

I tell myself that it is an investment, but I have modest investments in rental property and farmland (which cashflows via farming/hunting rights plus timber) and if my interests were strictly investment I would stick with these vehicles but I really like the idea of possibly being able to quit my job one day and become a full time entrepreneur.

"Why would it make sense to start out with 12,000 sq ft. Why wouldn't it make more sense to lease out the building and start with a smaller shop?"

Because I believe that an environment where capacity far outweighs demand best stimulates growth so long as this capacity exists in the form of capital investment. I also think that a large capital investment hedges my risk by lowering my operating costs which I could not recoup if things did not work out as I had hoped.

"So you crave a hands on activity? Which perhaps you don't get from your work?"

Haha, no - I have what you guys call "bad hands"

"Woodworking has to be one of the lowest profit businesses going. With headwinds coming from offshore competition, automation (which makes the ante for a new venture in the $100k + range), demographics that will not show an increase in demand for housing until 2020, what will technology come up with that makes the cabinet shop irrelevant?, those same demographics and other factors make employees next to impossible to find?"

Perhaps this is not the case at your shop, but the local shops that I have visited (which for my purposes are all that matter) are massively wasteful compared to a factory and, aside from economies of scale, there is no reason that a small shop cannot put into practice many of the same practices as well as take advantage of low operating costs. I am sure that these shop owners that I mention above are working on narrow margins, but their (high) price is a function of "this is what it cost me to make it" and "this is my percentage on top of that cost." They are also of the position that their product should be expensive because of its quality whereas I believe that a focus on quality should actually reduce costs. Then, if you have two people, each building the same cabinet out of the same materials, the guy with the higher quality should have the lower cost of production.

"The purpose of a business is to raise the customer's standard of living, i.e. this has nothing to do with making a profit. Any business owners purpose is to make a profit."

That's a bit pedantic and the same argument could be applied against any business, yours included, so how can you subscribe to this logic while still maintaining your own business?

From contributor Bl

Also, Pat, consider a residential cabinet job from start to finish. There are a lot of elements of this process which in no way involve making the cabinet, which is the only portion of the job that can be automated. Some industries (eg countertops) are able to implement "lights out" facilities, so called because they can leave the lights off as there are no humans involved in the process. Machine learning would have to come a long way for this to be the case with cabinetry and even if that were to happen the only companies that would be able to afford it would be the Woodmode, Krystal, Shiloh, etc companies and the end product of these companies is rife with waste for a couple of reasons, one being the costs realized by a retail location that sells them and another being that the factory subordinates all else to the cause of production and the product that results is not friendly in terms of installation.

From what I see, installation is the element in the process with the highest variation to which, from a value perspective, all other elements of the process should be subordinate. I know that this sounds very eli goldrat but the life cycle of a sale from initial contact to final payment can be simulated and optimized which any one of you could take advantage of with a base knowledge of statistics, probability, stochastics, etc - all available for the low cost of a textbook, and once you dive into these subjects you almost immediately find something that you can relate to your own business, a perspective that I wish I had when I was an undergrad.

Anyway, I guess what I am saying is that the automation that is available to a shop for <= 500k is sufficient to compete with the large factories.

From contributor Pa

I have not seen where overcapacity has been successful, maybe that is my ignorance, but I'm skeptical. It seems to me that your resources will be squandered that way.

Regarding waste and quality, Lean is not new to woodworking. I don't see how someone could use six sigma in woodworking save someone like Ikea.

Pedantic?, actually that sums up a good business plan. I was talking to someone the other day who said that there were 900 cabinet shops in San Diego county in 2007, today there are 300 shops. That is the market place part, and as to the profit part most of the surviving shops are trading dollars hoping for a better day.

That is always what happens following over-investment, and is part of the business cycle. Today the custom activity is dictated by ZIRP which stimulates projects with a long term payback. e.g. large healthcare buildings or high end residential. But much of this too will turn into over-investment as a result of excess currency and the business cycle.

To the positive, some guys that I see are doing very well. They have a niche. In this area some shutter guys are doing well, some high end kitchen guys are doing well, the bigger commercial shops, guys who do high end retail stores.

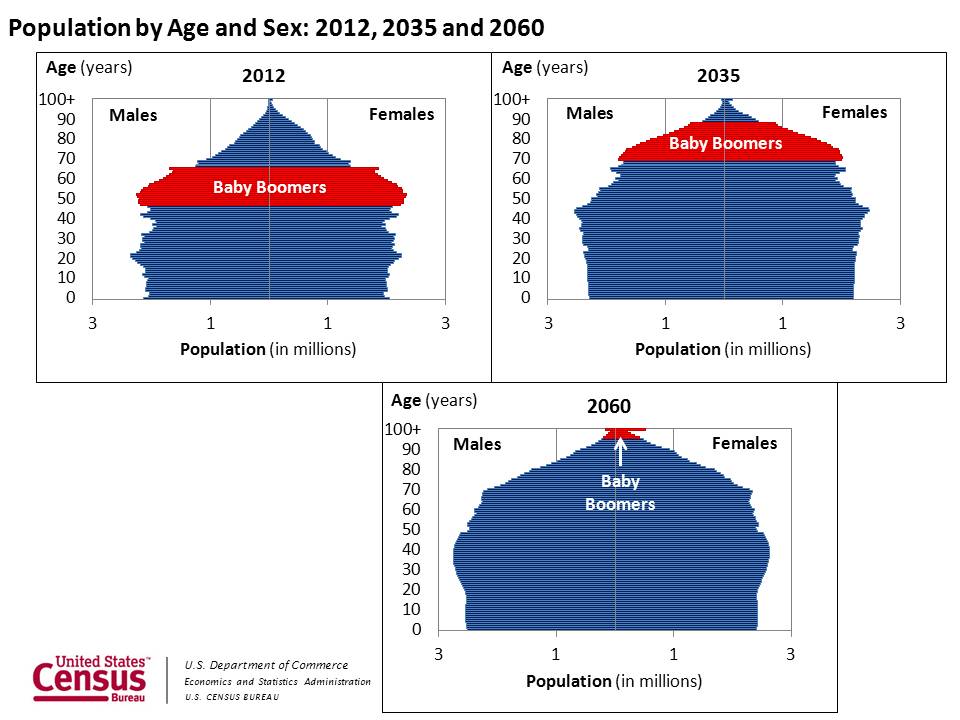

The past 5 years have been a very low phase of the industry. So it has no where to go but up. To that end the main driver in this business is home sales. What is not much understood is that a big part of the crash in 07 was because of demographics. People buy their first house between the ages of 25 and 35. Notice on this chart (2012) how there is a big dip at 30 and 40, that was the crash. Look at the big increase at 20 in about 5 years business is going to be good, if the politician don't F it up. Then look at 2060, not that any of us will be around. One caveat, in 2030 the boomers will be fully retired and will bankrupt the federal budget because of entitlements, don't know if that will trump the demographics or not...

From contributor Pa

There actually two constraints the other is finishing.

Jobs/the market grows in new ways.

Maybe in geography because of telecommuting and high cost of housing in Calif. E.G. population growth in Calif and other big growth states has only been 1.5% where as Utah and Colorado are high growth areas.

Maybe robotics has come far enough to allow manufactured housing to be attractive to home buyers.

A big part of the market has gone to China.

From contributor th

i'm not nearly as business savy as ya'll, but i'm not really sure i would start my business if i knew then what i know now.

one thing to familiarize yourself with is regulation. obviously, there are many, many considerations before getting into this business, but compliance with regulations all comes off the bottom line. enforcement varies by large margins and you really won't know how the code will be "interpreted" until your inspector walks in the door. one thing that came up for us just before moving to a larger facility - fire suppression. either the irc and/or fire code dictates an overhead fire suppression system for any woodworking business over 2500 sf. luckily, this was installed by our landlord (for us and the other business in our building) before we moved in. it cost him approximately $50k. furthermore, our fire marshal required a chemical fire suppression system for our enclosed, automotive spray booth. only $6k, but this came out of my pocket, and my pockets aren't nearly as deep as your's. never mind, the $750ish i'll pay yearly to maintain my booth, dust collection, and chemical storage permits. this goes up if the inspector finds anything.

you might also be reaching the wrong conclusions regarding efficiencies reached by high quality work. we spray the back side of products, even though the back side is completely covered (not cabinets) after installation because we believe it is the right thing to do. some of our competitors don't take this extra step. obviously, they've got lower costs into a particular piece and can sell for less, or make more than us. our only advantage is in creating a "better" piece. whether or not that message is accurately conveyed and ultimately accepted by the end user (accepting of a higher price) is our biggest challenge. our cost, however, don't come down as a result of making a "better" piece, though.

you might, or someone might link, the cartoon of the carpenter that talks to his buddy about opening a shop and building custom furniture. his buddy's advise is pretty spot-on. funny, but very true.

From contributor Bl

Regardless of demographics, there will always be someone buying cabinets and so there will always be someone selling cabinets. The question then, as in any business, is how to make sure that you remain as one of the ones who are selling.

I do think that there is some value in lean and six sigma and there are some very smart companies who employ both in some combination that is tailored to their situation (eg boeing).

I agree with you that the smaller the company becomes, the less applicable are some of the precepts. I read a lot of different forums like woodweb, some dedicated to industries other than wood, and on these forums you always have a few guys who are overly dogmatic in their application of lean and it works to their detriment. For example, I think that most small shops could become much more efficient if they warehoused completed parts or parts that are in some stage of completion but I could see this working in opposition to one piece flow as well as the low inventory levels plus the idea that a warehoused part is bad because you touch it twice. The trick then is to be able to quantify all aspects of your business and simulate without any bias towards catch phrases and see where the numbers actually are.

As to your comments on capacity vs demand, I feel like a couple of guys with a beam saw, p2p, dowel drill/insert, edgebander, case clamp, warehoused parts w/database tied to production software, etc would result in capacity similar to some number greater than 2 men using more basic tools. Each of these scenarios would be of the same capacity but the first case has high capital investment with low operating costs while the second has low capital investment with high operating costs. If these machines were purchased used at a fair price, then the investment at risk would be only that of transit and installation with the idea that the machines could then be sold at a fair price with minimal loss. The longer that you were in operation, the lower these transit/installation costs would be.

Assuming the high capital investment scenario, it would take demand years to catch up to capacity even if no improvements are made. I think that you stay in the cabinet business the same way that you stay in any other business, that being by offering the best value and keeping your promises, and it seems like each of these tasks become a little easier given high capacity and low operating costs.

From contributor Bl

Google, I am guessing that by spraying the back of your work you reduce the chance that it warps or takes on moisture.

If neglecting to spray the backs results in a significant failure rate then those who are not spraying the backs will experience higher costs, mainly the cost of repairing or replacing warped parts or the cost of lost sales due to a lack of repeat business and negative word of mouth advertising.

If neglecting to spray the backs does not result in a significant failure rate, then you are hurting your value proposition. By the way, what are you manufacturing that is not cabinetry but does get the back sprayed which is then not seen? If furniture then I would say it is not applicable because the furniture industry is so polarized into high and low end that there is not grey area between the two.....almost two separate, non competing industries.

Keep in mind that I am not arguing with you guys at all. I believe that we each know things that the other does not and that a conversation such as this might whittle away some nugget of truth as a result.

Happy Thanksgiving btw....

From contributor Bl

I say go for it - you have money to burn, no useful manual dexterity, and no knowledge of woodworking - what could possibly go wrong?

From contributor Al

Blake,

18 years ago I saw small shop in Germany that would gravity feed 3 CNC P2P machines with simplistic loading /unloading arms, the operator would stack the conveyer and load the programs and go home and get 21 hours of "lights out" production of a variety of parts. (7 hours per machine and then they didn't have enough in feed).

There are a lot of highly automated small shops in Europe. A house that is new construction can easily order cabinets from China, a remodel that needs to be done in 6-8 weeks cannot.

One of the reasons so much wood furniture production moved offshore is a lot of the factories were not modern in means and methods.

I guess you need to identify which markets you want to sell to, which markets you will switch to when they go away and how that will happen.

They are now using lasers to automatically layout office space lines for framing based on the plans and a few reference points. Its only a matter of time before a simple robot comes behind that system standing studs and attaching drywall. To keep costs down owners will accept larger scribes which will allow more standardized sizes (which could come from offshore) and that installation could also be automated.

My point is purchasers that plan in advance can buy quality at the lowest price point so how do you counteract that in your BP? There will always be a market for need it now or soon, the question is how do you differentiate yourself in that market.

A-

From contributor Th

Blake,

I'm curious what sort of business you envision? Custom cabinets? Semi-custom? Stock? And what sort of variety will you offer? Is this residential, commercial, or both? What are your sales channels?

From contributor Gl

We build fine custom furniture and also upholstery including our own frames. We sell to the very wealthy through interior designers. We are really old school with all of the tools to do the job but no CNC machines. We build things by hand and have been doing the same for the last 34 years.

I bought the business 13 years ago and I was a marketing executive for most of my life. I was also a good woodworker in my own right. I run the business and my employees do the work. I run it as it was run before. Very simple systems and a good lifestyle. When times are bad I put in about everything I had to keep the people working. I work 5 ten hour days a week. You might consider finding an old man that owns a successful business and buy it.

There is always risk involved like losing key employees or having the economy crash. There is risk in losing existing clients if you are not a good marketer. There is always risk period. You can start from scratch and invest a lot or you can buy and invest a lot. Either way getting rich in this business is not an easy task. Good luck in your venture/adventure.

From contributor Bl

Alan,

I do hear what you are saying but what I see is a different situation. I live in an upper middle class neighborhood. I would say that no one in the neighborhood is really wealthy but no one is struggling. I do pay attention to the new construction in the area as there has been a lot in the last couple of years and for those homeowners that I do know, I can promise you that outsourcing the cabinets from china, themselves, would not be under consideration, nor would they approve of their contractor doing the same. For the most part, I see painted, floor to ceiling cabinetry that is scribed to the floor at the base and wall at the back and side. The cabinets from china that I have seen come in boxes, require assembly and are not of the quality that I see going into homes in the 400k - 500k range. Also, I would imagine that a cabinet installing robot is a long ways away and even so would require constant human intervention.

Glen......semi custom I guess? I do realize that sinks have to center on windows, cabinets should fall equidistant from casing, etc but I also feel like this can be accomplished by custom widths on a small portion of the cabinets while still maintaining consistent sizing on fillers. Ceilings would be a bit more difficult as an odd height could result in all wall and tall cabinets being built to a custom height, but the company that we partnered with for my senior project would build anything that you like but the price was steep for doing so and much more friendly if you stayed within the standard sizes and configurations that they offered. Also I think that I would have to be smart with my offering, eg people want a wide range of finish options but would probably be satisfied with just a few options on doors, and if not then they could take their business to a full custom shop. I don't think you get anywhere by letting the customer dictate exactly what you build.....you build what you build and they can buy it or not - it wouldn't be for everyone.

I haven't put a lot of thought towards sales channels but I do recognize that sales would likely be harder than production, although if your production is right and you offer value that other shops do not then I think the sales part becomes much easier, especially once you develop some momentum. If I had to speculate on sales channels I guess I would say contractors, designers, kitchen centers, leads groups, etc. Contractors, designers, kitchen centers? Each of these trades competes within their trade largely on the value that they receive from their subcontractors.

From contributor Bl

Also, rather than paying for advertising that, outside of your website is probably a waste of money anyway, why not approach some contractors or designers and offer to do a job at cost? I think that would be more effective than advertising and unless there was some mistake made it would not cost you anything.

From contributor Pa

In one of the richest zip codes in the US around here I have heard over half of the cabinets are from China.

The marketing plan dwarfs the manufacturing plan in importance. One hint growth is the key, location should be subordinate to growth.

As to Lean, forget the ptp boring machine and go with a router. Which would take a lot less space than 12k ft.

From contributor ca

get Paul Downs book and read his story about his partnership experience.

From contributor ri

I was raised on a farm. This plan reminds me of the question asked of a farmer. "How do you make a small fortune by farming?" "Start with a large fortune and just keep farming until it gets small."

From contributor Bl

Rich,

This forum is full of people who are successful owner/operators of small to medium sized shops. If some of them had, in their early days, come upon someone wanting to offer consulting and capitol to their business I doubt many would have refused and I doubt that they would now be worse off for having done so. The trick to this is finding the right person for the job.

A lot of businesses fail due to being under capitalized rather than a lack of knowledge of their craft. Also, given the amount of automation available coupled with the number of items that can be outsourced, I doubt that a lack of woodworking knowledge would be much of a hindrance given the cataloged offering that I am considering.

Cabinetmaker, that is a pretty small sample size.

From contributor Jo

Blake, why don't you burn 50K and kick yourself in the nuts a few times. It would be quicker. Just take your basic premise of finding a knowledgeable employee partner. In construction you have to hire ten guys for everyone that sticks. I have seen it for years. What are you going to do between guys? Not being an accomplished cabinetmaker yourself how are you going to vet prospects for skill? It goes on and on. If you throw money at it long enough and are as smart as Einstein and wily as a coyote maybe just maybe you might survive.

From contributor Ol

When I started doing custom woodworking, I liked the idea of doing custom woodworking better than actually doing custom woodworking.

When I had my business, I liked doing custom woodworking better than having to run a custom woodworking business.

As the sun rises on my fifth decade of doing custom woodworking, I like talking about doing custom woodworking in the past tense.

From contributor Pa

What strikes me about this thread is the absence of a marketing plan. EVERYTHING ELSE is irrelevant.

From contributor Ma

Blake,

I do think it's possible to pull off what you're considering.

Everything you've said about out mfg. your competitors is possible.

Pat Gilbert is 100% correct about having a marketing plan in place. Just because you build it means that you can sell it.

You may not want to talk about the location of this on a public forum, but if you're so inclined, click my name and send me a private email on what city or locale you're thinking about.

I sell components so I wouldn't feel threatened by your presence in my area. Matter of fact I would hope to sell to you.

I have done very well in the woodworking business and have no regrets.

Mark

From contributor Bl

Pat,

I do understand what you are saying and I add that more than just a marketing plan is in order but rather a comprehensive business model.

I am not concerned about the marketing end because I have involvements that gives me access to sales channels that I would rather not speak about so as to maintain anonymity, and not because I am notorious or anything but because I do have associations with people who read this website and I would rather at this point that these people not be privy to my thoughts.

That said, I still maintain that, over a long enough period of time, it is the value of your product or service that serve as your best marketing and any marketing expense that indefinitely increases operating costs negatively affects your value proposition.

From contributor Pa

Another thing that strikes me is how successful people are at marketing to

wood-shops. E.G. FastCap, True 32, Rockler, etc.

I think as always, another instance, that we suffer from a case of looking through the magnifying glass instead of the binoculars

From contributor Pa

Then you fail to realize that the marketing plan dictates every other aspect of your business, certainly advertising.

From contributor Bl

Marketing to woodworkers is a bit easier because of sites like this. Also, marketing is a bit more important to companies like fast cap that sell nationwide.

That said, I suppose I do have some thoughts on marketing:

A professional, intelligently optimized website is a must.

If your city has some sort of home tour where builders showcase recently completed projects, this is an invaluable opportunity for you. First, it seems like you have a mix of high end spec and custom homes. If it is a spec, the builder needs to cut costs to maintain his margin and if it is custom, more often than not the builder has made concessions in price to the homeowner so that the owner allows the builder to enter the parade. Either way the guy is after value which gives you the opportunity to offer concessions on your price so as to get your product in the tour as well. What if you were to do this job at below your cost? Is the money that you would lose on the job any different than the money that you would pay in advertising expense?

Also, have you guys considered youtube? If I want to learn about anything these days, I go on youtube. If I were in the market to purchase cabinetry and went on youtube to educate myself about cabinetry in general, and there were some guy on there giving out tips and info on species, finish, construction options, pricing expectations, etc AND if this guy was in region then he would be one of the first people that I would speak with. Additionally, if you have enough views on your youtube channel then you get kickbacks from youtube so its like advertising that pays you money. Go to youtube and type in Rev Zilla to get an idea of what I am talking about.

Traditional advertising for a cabinet biz is a waste of money imo.

From contributor Bl

Pat I feel like a business is an integrated whole such that any one part affects any other part. I just feel like passively marketing your business by offering similar product cheaper will, over the long term, beat the hell out of spending money on advertising as well as reduce costs in sales in that you are not always busting your ass trying to sell people on a product that does not have strong value.

People are smarter than that, they don't want to waste money and more importantly they don't want to be taken.

From contributor Pa

My answer to your marketing ideas are Meh

As Socrates stated the biggest barrier to knowing something is not knowing that you do not know. BTW engineers seem to suffer from a lot of this.

That is a bunch of supposition and conjecture.

The first thing I would do when studying this subject is to look at what is working.

One thing I see working quite well is the kitchen centers that import from China.

The other thing that I see being quite prescient is demographics. Most kitchen remodels are purchased by people between the ages of 50 and 60. The biggest group of boomers were born in 1956 and 1957. That means that in a few years kitchen sales are going to shrink a bunch especially when the free money disappears as it did in 2007. You can always count on government to make things worse.

BTW government contracts are a nice niche, if you don't mind being a whore, of course they are going to give the money to somebody.

From contributor Pa

And you think you're the first person to think of that? Lean is about CONSTANT improvement, hardly new to woodworking.

BTW marketing has f all to do with you or your feelings, it has to do with the customers feelings, mainly the woman's.

Hint people BUY for emotional reasons. A marketers job is to bust his ass to find out what those feelings are.

From contributor Bl

Engineers also routinely suffer from earning a healthy 6 figure salary.....do you?

Just how large is the business that these ideas of yours have grown, Pat?

From contributor Bl

btw that's "engineer" not in the loose, Woodweb sense but "engineer" in the "i went to college, majored in some field of engineering and now I work in that same field" sense of the word.

If you don't believe me then look at the jobs postings......all of you are hiring engineers these days....

From contributor Pa

Don't get all supercilious with me. You are taking this personally. BTW the engineers postings are not for degreed engineers. BTW my dad and 2 brothers are engineers at the top of their fields. They SUCK at woodworking so stick that in your pipe and smoke it.

From contributor Bl

My bad, yea I did take that a little personal. I have yet to cross the year 35 threshold and sometimes it shows.

From contributor Pa

The marketplace is going to be in your face plenty (especially if you get into commercial work), get used to it. Not too many warm fuzzies in this field.

From contributor La

If you have worked out your plan that includes a plan B, go for it. I've been @ this a long time, many ups & downs. I have a small 25,000' shop. Nothing that I consider automated in the lights out sense. Good CAD CAM software feeding a server that feeds a beam saw, P2P, CNC router, bore & insert machine. Machines are all connected by gravity conveyor. Final destination for box cabinets is the bore & insert doweling cell that includes glue injecting and pass through case clamp. This system can put out a lot of work. Eliminates much handling and does not include any stocking of parts. (That increases risk & costs.) No time is saved in stocking parts, actually the reverse is true. If you touch something w/o adding value, you are wasting.

We are a commercial only shop, no kitchens, well sort of, we do make break area cabinets. About 1/2 of our work is curved in one way or another. Call it a niche. We've never advertised, another failure I suppose.

From my experience, I would not buy another P2P but rather a self load, clean, unload router, less labor. If single sheet cutting on a beam saw the router will finish a sheet just as fast and the parts will be fully detailed. I'm guessing you are going to sell Euro box cabinets.

Equipment: Router @ $170K, Hot air bander @ $230K, Bore & insert @ $70K, Conveyor & transfer car $35K, Manual case clamp $60K, a few assorted tools $20K, software $40K, office equipment $20K. Some set up costs. This is a new set of the minimum items, middle of the productivity road. $645K. If lucky and with some time, used @ 1/2 that. Setup, training, debugging, 2 months+. Operating capital $350K. $1,000,000 up front. $700,000 on the cheap. Assumes buying out of doors, finish, drawers etc. Production about 1300 cabinets per month. Staff 6+. Under ideal conditions, after all bugs worked out and a perfect flow of work 1600 cabinets/ month? Margin?? 10%?? Alan, how far off am I?

From contributor Bl

Larry,

I didn't know what a hot air bander was (thought they were cheap pos < gluepot) so I did a youtube search and that is impressive......that said, wouldn't that be more of a commercial machine that wouldn't be of much use in bonding pvc to plywood? I assume that the idea is that it fuses pvc edgebanding to melamine?

Are there no exceptions to stocked parts? What if you stocked 4" x 96" rips and designated this material as something different in the software such that these parts would not be sent to the router, then nailers, stretchers, ladder base material, and "A" drawer sides/front/back (assuming you are ok with 3/4" plywood drawers) could all come from these rips using saw stop and cross cut saw. Then you wouldn't have to onion skin or tab parts on the router. Also you could then run your 1/4" drawer decks first on the router and someone could be making drawers while the rest of the job was cut? Your number is big but it's not so different than the 500K number that I threw our earlier. I don't have 500K liquid, so I would be borrowing and I guess it would be a question of whether this money would be put to better use on investment property.

Sounds like you have a pretty impressive operation which makes you like.......the white unicorn of the woodworking business given the absence of a marketing plan, eh Pat?

From contributor Pa

Advertising and marketing are two different things, hopefully you realize that?

Larry has been doing this for 40 + years, I would venture a guess that if he had a million dollars worth of resources from the get go he might have been inclined to squander some of it, from ignorance.

His marketing plan is simply building curved store fixtures. And it works!

But hey interest rates are cheap you are clearly very smart, you have few woodworking skills, no marketing plan, no woodworking knowledge "what could possibly go wrong"?

From contributor La

I don't think a hot air bander cares what the substrate is any more than a glue pot bander. Alan has one. Ask him about it. We rarely use plywood. We use either prelam or melamine, some MDF but it doesn't like edge fasteners. Plywood can be a struggle on Euro box construction. It isn't consistent in thickness and often not flat. Edge fastening tends to spread the plies. Almost all the European high $ import cabinets are 16mm melamine. Almost all come as KD and are put together by the dealer. They seem to have a snob appeal. The few that I've installed have very nice quality ABS banding on the doors.

I wouldn't make my own drawers for kitchens. You can buy really nicely made hardwood, dovetailed drawers for less than you can make plywood drawers. And, most importantly, they will help sell. Much of our commercial work uses doweled melamine drawers with 2mm PVC. On a typical nest you will have some space too small for cabinet parts other than stretchers. Just set the software to tab only those parts below a size that doesn't hold well. It will only take the router a few seconds to cut them to size, eliminating another handling. Stick within a system. Buy what doesn't fit your system, it will allow you to make more kitchens. I've been down the road of trying to save $ by making ahead and stocking semi finished parts. No longer do it.

Next August is the biennial IWF show in Atlanta. I highly recommend that you make a list of all you might be interests in and go. There is always something new and it is a cheap education. They publish a lot ahead of time so you can make your list and "checking it twice!" Best part is at many booths you can talk to the technicians and get a lot better information than talking to a salesman. Google IWF 2014 to get an idea about it.

From contributor ri

Blake,

I actually had a person buy into my business in 1995 as a partner. He promised accounting help done by his wife, promised to do marketing, and since his son was working for me, it could really be a great benefit for all. After a few months it became evident that his idea of marketing was to give me some phone numbers to call. He knew nothing about woodworking, so could not quote or even talk the prospect about the project. He became angry because I started working 8 hours a day instead of the 12 I was doing. His son became lazier and thought he had an "in" and didn't have to report to me. I got fed up and bought him back out. That's when I found out his wife had not notified the state of the change from sole proprietor to LLC. The state then told me that I would be paying a beginning business rate on the workman's comp since the business was no a new business. It cost me thousands for that little adventure! So maybe some of us have been through a partnership deal with someone that has limited woodworking experience!

From contributor Ki

Blake - I have owned a successful shop for over 25 years, doing niche work, with little/no competition. While we are local now, we were at once - before Crash - stepping out on a national level. We are easily between a net of 8% to 18% profit every year, even in the bad ones. We have never advertised. We have done 4 kitchens in 25 years, each was one that no one else would attempt - curves, woods, design, etc. I could never compete with regular kitchen people, nor would I want to. Sucks the life out of you real quick.

I can say that the direction you are going is leading you to the most difficult path you could plot - mainline kitchens. You will find a lot on this since there is a lot of constant, public, head scratching on the subject, as well as machinery and software galore to help makers make sense out of their tremendous investments. Lots of competition, lots of outside factors, lots of change, lots of potential pitfalls. If your idea of running a business is like Indiana Jones escaping the temple, well then, kitchens has to be it.

By definition, you will not hear much about the quiet money makers, only the loud and squeaky and queasy.

As Glen suggests find an existing shop with an Old Guy, and buy it and build on that. I just happen to have one.....

From contributor Bl

Yea I do like the idea of a niche.....I had thought about closets also which is why I was considering pod/rail vs router bc so many parts would receive drilling on both sides then.

Also someone mentioned plantation shutters and the local shops do seem to be doing well with those but when it comes to closets and shutters there is very little info on design and manufacture.

From contributor Pa

Mitch will probably take exception to this but I know a guy who has been doing shutters forever but has never manufactured them. The manufacturer is Hecho en Mexico and has a key to his shop and delivers them at night. This has been his MO for many decades and he does very well.

Is the marketing plan stock price going up?

If you gottsta go into woodworking you might do well to emulate those who do well. Larry e.g. drives around in a Bentley.... or was it that he spent the price of a Bentley on a machine or two, can't remember?

From contributor Bl

Not for me no, the marketing plan stock price is not going up. Further I claim that if you take a poll of all those on Woodweb you would find that less than 25% have a formal marketing plan or even a written business plan for that matter. I do think that a business plan/model is necessary and I do think that marketing is a component of that but I don't think that it is the panacea that you think it is.

The good news is that everyone has a marketing plan if the idea is to point to the positive aspects of a business that distinguish it from others (eg radius work) and call it a marketing plan because it suits your narrative.

To me, marketing plans are the purview of guru books and bs business theory classes, as applicable to the workplace as that discrete math course that I had to take.

From contributor Bl

Discrete math is actually pretty fun, albeit useless.....see if you can get this without googling it (its sort of the poster child for discrete math):

Ok so lets say that you are at a party with = 2 people in attendance. Prove that there are necessarily two people there with the same number of friends at the party.

And while we are at it, the poster child for probability:

I think there was some game show from a long time ago that had the competitor choose from one of 3 closed doors, behind one door there was a new car. After the contestant made a selection the host would not open the door but instead open one a door with nothing behind it and then give the contestant an opportunity to change his initial decision to the one remaining door. Based on his decision of whether or not to change, does his likelihood of winning the car go up, down or remain unchanged?

Pat, perhaps you could take those two problems and stuff them in your toolbox beside your marketing plan.

From contributor Bl

oh shite that should read that the party has >= 2 people in attendance, ie any number greater than 1.

From contributor Pa

Sounds like we should be asking you the questions?

BTW everyone has a marketing plan whether they write it down or not.

E.G. I would echo what KT said. I doubt anyone here is doing the same thing they started out doing. Their marketing plan was ad hoc you might say.

You remind me of another millennial that visited the wood web a while back. Care to guess what characteristic both of you have in common?

From contributor Bl

Haha, that could have been me. I have posted on Woodweb once or twice before under various pseudonyms so as not to wear out my welcome. But in case not, what is it that we had in common?

From contributor do

Mel is that you? LOL

From contributor ri

door shop guy,

Thanks for the laugh!

From contributor Pa

The ability to ask a question without the slightest interest in the answer.

And trying to camouflage a strong interest in self aggrandizement.

Cya

From contributor Bl

Well summed up, Pat. Extra emphasis on the self-aggrandizement, too.

As for Mel, what ever happened to her? I hear she got fired for spending too much time trolling Woodweb...

From contributor Ma

Google, here you go ... it's funny every time!

From contributor Ma

Or ....

From contributor Bl

I have said here that I have a monthly excess and that I have modest investments and perhaps that is seen as boastful but I mostly have a monthly excess because I am frugal and modest is hardly a word to be used it I were trying to boastfully exaggerate, also I only included this info because I feel like being under capitalized is an issue that is hard to overcome in a startup business.

In general, anytime you see someone new come on with some interest or question, especially someone considering making a go of it, at least half of the responses are guaranteed to be negative. Chiming in with criticism is an easy thing to do because you are guaranteed that others will rally around you but I am not sure what you get out of it.

I understand where Pat is coming from because, from what I have seen, he is a serial antagonist who will take an opposing stance just for sport unless given the opportunity to fawn over smartlister.

As for the rest of the schoolyard negativity, you guys should consider being positive for a few days and certainly not for the sake of me as I could give a shit but in the interest of your own positive outlook.

From contributor Pa

Well, not everyone chimed in. But has anyone approached you privately? If not, I'm not sure how this discussion advances your goal of finding an entrepreneurial partner. I had a partner for a while, and he had some weaknesses, but on the whole he was civil, supportive, and willing to listen to different viewpoints, and on occasion he even changed his opinion in response to new information.

Good luck with your business. Everyone starts a new effort from a position of ignorance. It's what happens next that counts.

From contributor La

Like Paul, I also had a partner. Very much like his, actually. I had made the shift from "hands on" to business and manufacturing, he did not.

For the record, I drive a beat up pickup. And yes, I have spent the price of a Bentley on equipment.

As for all the marketing, business plan, advertising stuff, you just need to figure out what the market has an interest in, that is not being met. Not easily done. What are you going to offer that is not already available? Beating the established players on price alone is likely an up hill battle. They may be inefficient but they likely have advantages to offset that: purchasing power, distribution channels, name recognition.... All of those take time to develop.

I've made my share of mistakes, tried to go head to head with big companies. I liked to think our stuff was higher quality. Even if it was, from the stand point of a purchasing manager, his job is to fill a need at the lowest possible cost. Could I sell higher quality at a lower price or did I need to find something the big guys didn't like to do?

From contributor Pa

`Admittedly there is a certain amount of sport in it. But if all you get out of what I'm saying is antagonism then you don't get what I'm saying.

You have a strike against you because the millennials have been raised to believe that self esteem is all important without any empirical test to demonstrate that they are good at something. The ultimate empirical test is the market place.

I'm arguing (always arguing) against the illogic. Which in your case is substantial.

The most important decision anyone makes in business is the type of business they go into.

My unsolicited (actually it was solicited, just not what you wanted to hear) advise is to do a poll of the answers on this thread and see what the most common answer is, and at least consider it.

The guys who are successful IMO do a lot of looking and listening to discern where there is opportunity.

From contributor Ca

I think there are at least three Blue Oceans left in the custom kitchen business, maybe four. In all of these fabrication is the simplest part.

The internet has created some opportunities that have not yet been fully harvested or even harvested at all. Exploiting them will take a package of skills that are not common in the woodworking industry.

While Blake's arguments are fairly articulate he's still trying to bring a red ocean strategy to a blue ocean world.

From contributor Bl

Blue ocean strategy - may Blake be as successful as the Tata Nano. Keep your fire extinguishers and insurance up to date and try not to run into anything more substantial than a squirrel.

It will be smooth sailing out there, smooth sailing all the way.

From contributor Bl

Pat Gilbert (shaking fist in air): "You millennials get the hell off of my lawn!"

Actually there are some components of blue ocean strategy in my thoughts. Keep in mind that the examples given in blue ocean strategies are all companies that compete on a national scale, eg southwest airlines. To me, their strategy was to have a company that offered a fraction of the routes that their competition offered and by doing so offer a greater value so long as your needs matched their offering.

I dont think that you are so often competing against companies that are several hours away, so if you are talking about blue ocean strategies then the blue and red oceans should be considered in terms of your local competition and what they offer and at what price they offer it rather than the woodweb consensus of the perfect competitor.

From contributor Ca

Let me get this straight.........

You suggest that Pat Gilbert is unrealistic yet you somehow think you are going to turn a wage worker into an entrepreneur?

Have you every tried to get a cat into box to take it to the vet?

From contributor He

This was a good read, Thanks Guys!

From contributor Pa

The competition for kitchen cabinets is from China and nationally from the national cabinet makers for Home Depot and Lowes. On the commercial side the competition is at least national, for some of the commercial work that too comes from Vietnam et.al.

From contributor Bl

I just don't see the chinese competition angle, at least not in my area - I mean yea we have them but not in the higher end homes, and if you can't beat the box stores on value then u need to gtfo of the cabinet business. If you don't believe me then go have them quote something.

That's a straw man, Cabmaker - I didn't say that pat was unrealistic and I didn't say that I would take a wage earner and turn him into an entrepreneur and if you read the initial post on this thread it questions whether the right person, that being an entrepreneur who was open to a partnership, could be found and concedes that much of this hinges on that person.

If any one of you could go back in time to when you were considering going into the business, write down your thoughts at the time, and fast forward to current so as to post these same thoughts on this board, they would be received similar to my own because, for some reason suggesting to a group of cabinet makers that you are considering going into the cabinet business is like.....deciding that you want to be a movie star or something.

From contributor Ca

Blake,

There are also some other considerations the MBA programs don't teach you about.

Woodworking success in the higher end homes has very little to do with fabrication.

You have to learn to navigate the politics of the design process. In most of these projects you will be the sole vendor on fixed bid basis. The contractor and designer will be there on a cost-plus basis and can sometimes be somewhat ambivalent about how long the project takes or whether or not you get decisions in a timely manner so as to allow the rest of your projects to stay on schedule.

You need the ability to find the snakes in the project, slay them and come up with a workable plan in such a way that nobody gets their feelings hurt. It's like being in the Secret Service. You have to be willing to jump in front of any bullet in order to keep mud from splashing on the Grand Poobah's coat. You have to be resilient enough to not let it matter when the contractor doesn't really mean it when he "We'll make it up to you next time!".

High end work can be a barrel of laughs when a project is slated for 3 month delivery deadline but the site isn't ready for 11 months. It's hard some times to convey a sense of urgency to customers who own 4 houses in 3 countries or get their representative to understand your situation when their salary depends on them not understanding.

You have be able to do all of this cheerfully. If you are going to wither under the admonishments of grumpy guys like you find on this forum you should see what my customers are like. Its like how are the Republican candidates for President going to stand up to Putin if they can't stare down Rachel Maddow.

From contributor Ca

and then you gotta learn the dialect......

it's like two rug merchants haggling over the price of a rug, talking about how beautiful the blue sky is but never mentioning the rug....

Getting the hired help to act like business owners will actually be the easy part.

From contributor Bl

No! BS like that is exactly the sort of fat that you should be cutting out to add value to your product. I can't believe that all contractors and designers have such scheduling issues. Now, I understand that in estate level projects that schedules are harder to maintain and the expectation is that you will be flexible and accommodate this but those projects are not really the sort that should go to the full, high end custom shop that wants to deal with that bs. Again, 300k to 500k is probably the sweet spot that I am looking at. I think that I read somewhere on this forum that the man who sells a Porsche drives a chevy and the man who sells a chevy drives a Porsche and I think there is some truth to that.

I assume that you have written contracts with your customers, these contracts should specify a delivery date as well as a plan B which includes fees for temporary storage as well as loading and transit.

The sorts of problems that you mention cost someone money and if you allow it to cost you money then either your other customers have to pay this or you pay for it. Why allow some contractor or designer to raise your operating costs? People trust you with their money under the assumption that you are a professional and this assumption should be reciprocal.

From contributor Pa

If you knew a fraction of what you think you know, you would realize that high end jobs are handled by General Contractors. General Contractors don't buy cabinets from Home Depot. But they definetly buy Chinese cabinets for high end houses as they think that they are a better value. And by high end I mean some of richest zip codes in the US.

From contributor To

Cabmaker:

After years of doing work through interior designers, I would say that you have captured the essence of the process, at least as it involved my experiences.

Someone should make a video similar to the classic "I Would Like To Hire A Custom Cabinetmaker" and call it "So You Want To Do Work For An Interior Designer".

Any takers?

I'm not sure if Blake has ever had contracts with people who not only do not care about your workflow position or contractual points, but don't have to, as they control the money, and are much more accustomed to handling people like you than you are in dealing with people like them. Either they or people they employ will circumvent and obfuscate your contractual points so that in the end, you will be happy to install your work and finally get paid, whenever that will be.

Blake, good luck with your endeavor, as you could easily be someone I have done work for in the past; pretending to ask professionals for their advice, doing whatever you want to do anyway while being argumentative about that advice, and believing that those professionals whose advice you sought are complete incompetents.

From contributor Be

I have been involved in several residential projects where a single room had over 100K in millwork. Several rooms had two or three times that. Now, we are a sort of anomaly from what I hear about other shops, but I've only signed one contract in 30 years, and we work with professional designers in less than 25% of the work we do. Most designers have far less knowledge about period style and design than I do, and much less ability at drawing it or integrating hundreds of details within a room. They can give me the bare bones, then please get out of the way.

As for timing, yes, there are problems like living with a curved stair for ten months. I learned long ago to quote all work with payment due upon "shop completion". I may let them hold 10%, but I get paid when we are done, regardless of where the project is.

Point is, there are all kinds out there, so generalities are not as reliable as one may think or want. It is possible to determine what you want/need to do, then drive the market to your door. This will certainly be easier than trying to break into a crony filled market that is capable of simply freezing you out if they like. Often people that are outside that crony cabal want/need what we do, and appreciate the fact they can get equal or better work more easily than through other, more restrictive avenues.

It is a big world.....

From contributor Bl

Pat do you even do any residential work and if not then where does your knowledge of how residential contractors operate come from?

From contributor Bl

Ok then tony if they do that once then fine but why let them do it to you twice?

The dynamic between a contractor and subcontractor is not so different than that of you and your employees, albeit more easily severed. You have certain obligations that you have to uphold or your employees will find somewhere else to work that suits them better, unless they have no other option and that sounds like a miserable situation. If I were u and felt that I had no options rather than to work for unprofessional contractors who do not respect me or my schedule, the very thing that I must maintain if I am to meet his schedule assuming that he is on time the I would find something better to do and not deal with any of that.

From contributor Ca

Blake,

Cabinetmaking been around since the days of the Egyptians. If this industry could have been tamed it would have been.

You're not the first person to notice the price point of our product.

From contributor Pa

I read about it on a forum somewhere...

I need to come up with a name for this phenomena, similar to Godwin's law, that states: a thread started by a millennial, if it goes on long enough, will always degrade into the millennial patronizing all those that the advise was solicited from.

I'm thinking the " the millennial law".

Any ideas?

From contributor To

Pat Gilbert:

For your "Millenial's Law", perhaps "Gilbert's Razor" would be an apt descriptor. You will be quoted in sociology journals for decades.

Blake:

Your customers are where you find them, and they are not always your first choice of personality types.

Perhaps Ben Darenback has the good fortune of quality customers, but perhaps it was not always like that for him.

If he has acquired better customers over the years and dispensed with the customers who are more of a colorectal sphincter terminus (in the shop vernacular it rhymes with "glass bowl"), then more power to him, but that is a lengthy process, and not an instantaneous occurrence.

Sometimes you have to acquiesce to your customers wishes. The client is the designers customer, and the designer is yours, and everyone's job is to make the designers client happy. The designer, especially in the beginning, puts you in touch with customers you would not otherwise have access to.

Sometimes things go smoothly, and sometimes they don't. When they don't, you have to play the game, or you will not do work for them again. If you have other customers and you can afford to be without their work, great. If not, then whether or not you have the contractual advantage and logistical foresight is immaterial, because it will be viewed as impeding the end game, which is to make the designers client happy.

You can get paid, but you need to be available to deliver and install when they want it, and if you are juggling several designers projects that are in similar flux, well, to say it is frustrating does not do justice to what you would be actually feeling.

Everyone has a different experience with the business, but it is not always the way you imagine it at the beginning. Just sayin'.

From contributor Pa

That is good Tony, I like the ring of it. Blake prefers to use the opposite of Occum's razor, IOW use as many assumptions as possible.

From contributor Ca

Will there be an homage to Clint Eastwood on the wikipedia page? Maybe a Gif of him driving by slowly in his Gran Torino?

From contributor To

Back in the day, Pat Gilbert "stacked millennials like cordwood".

From contributor La

I'm sure glad I don't do residential work. OR I'd have all those problems with designers and GCs. It only takes the designers I work with 2 to 3 months to pick a laminate, then want delivery in 2 weeks. The GCs are better. At the beginning of the project they have a schedule all neatly printed out. Most of our projects are out of state, so I can't take a look, & the project managers always tell you they are about on schedule. But you'd best have someone spying on the project near the ship date! No one gives a damn about our schedule, infinite capacity is assumed. It isn't always the GCs fault. We have two projects currently that were to ship in November. Now delayed until sometime in January or February. The problem is with codes administration in S CA! Pat might know something about that.

So, If I read Blake correctly he would just not work for clients like that. Good, that means we will never be competitors.

From contributor Bl

Mel > Blake.

From contributor Bl

Ok so correct me if I am wrong but what most of you are saying is that in a given project of yours, not you but your customer may have issues that cost you money and you are ok with this because you have some sort of relationship with this person and it all comes out in the wash over multiple projects, right? Now, I assume that if you are late with your portion of the project (especially in commercial work) then there is some sort of penalty for this, right?

Again, why can this not be reciprocal? Assuming that you have a contract why can there not be wording in that contract that basically functions as an if-then algorithm which branches along lines of things that you cannot control yet do cost you money?

If you are up front in introducing this and if you approach it from a perspective of "Look I want to give you the best value for what you buy from me but to do that assumes a best case scenario, therefore, anything that deviates from this best case (through no fault of mine) will constitute a change order."

Is your relationship with your clients really so tenuous that you are afraid to ask them that they (rather than you) pay for their own mistakes?

Pat, maybe its just the millennial in me but I tend to think that in business, its ok to be forward with someone when discussing money rather than act like some shy schoolboy at his first dance about it.

From contributor Pa

Once again the antithesis of Occam's Razor...

From contributor Bl

The naive is strong in this one.

But it is topped by inexperience and lack of understanding of human nature.

You'll go far, lad, just not in the woodworking business.

From contributor Gl

My job is to make my customer's job easier. I do all I can to deliver on time and above expectations. If you start a new business and right away come up with a more complex contract or new rules for doing business there will always be a dozen competitors who don't do that. How are you going to attract new customers with your attitude? Better figure out that part before you throw money at the dream.

From contributor Pa

Blake: you're wasting your time here. Buy some equipment, rent a shop, and get started. You'll find out whether you're right or Pat Gilbert is. That's the beauty of this kind of business: there's nothing stopping anyone with a few bucks and a bright idea from giving it a go. No credentials required. In most jurisdictions, no special licensing. Just you, your money, and your idea of how things should go. Have at it! If you're right, you'll be laughing all the way to the bank.

Good luck!

From contributor Bl

Glen, if you have enough in your bids to absorb costs incurred by things that are out of your control then you are too high and the people who are paying the bill for this is the professionals who routinely are on time and are not a pita.

There is a post from a few threads back from someone who is of a similar thought as me, and I'm not suggesting that an investment in machinery would bridge the gap between what he and I know about the business but its still an example of a guy who realizes that the tail CAN wag the dog. This guy understands the value that he adds and if the customer doesn't then that's fine they can take it down the road because he's got a damn pair.

Now in reading this please don't think that I am pointing to a working example as an argument against Pat's 14th century soft science - that would be craziness. I am only saying that there is (at least) one exception. This guy wrote:

"Not sure what you want elaborated on. We operate pretty old school. $2k SawStop tablesaw cuts all of our boxes. $5k edgebander bands all our boxes. A Dewalt $50 corded drill drills all of our shelf holes. Yeah, we pretty much do everything backwards of what the industry tells you to do. We sell for too little. Don't use technology. Don't advertise or market. What we do is call folks back immediately. Are always on time. Sell at a price point where nobody in our price point is even remotely close to our quality level, which allows us to be in extremely high demand and set the terms. Have a great looking finish. Tell problem GC's and designers no thank you. And squeeze every last drop of efficiency out of our system without going into debt. Lastly, we treat our clients and our vendors like we'd want to be treated. But boxes, no. I imagine most everybody on Woodweb could knock out more boxes per week.

From contributor Gl

You seem to know it all so just put your money where your mouth is. We do charge a lot for our furniture. One little secret is that there is not another place in the state that can build what we do. We have a very special niche with a good string of the best designers in the market. I don't make a killing but I can absorb a few changes or maybe special woods or parts for my customers. There are no other professionals paying for anything we do. They all went belly up in 2009.

From contributor Pa

"Blake: you're wasting your time here. Buy some equipment, rent a shop, and get started. You'll find out whether you're right"

Yea, you don't want to over think this.

From contributor Ro

Blake = Mel.

From contributor Ke

Wow that was an interesting read. Lots of good advice from guys with decades more experience the what I've got.

As to finding a partner with all the qualities you are looking for (knows the trade, entrepreneur, good business mind, etc) I honestly do not know what he would need you for, unless he could not get the $$ that he needed from the bank.