Question

One of the more tedious items I've encountered over the years has been fastening outboard refrigerator end panels - the ones that are not supported by base cabinets, and in some cases, not supported by upper cabinets either. The real challenge is when the panel falls between the studs (and retrofitting blocking is not an option). And the worst case scenario is with a Sub-Zero refrigerator - absolutely no extra room at the sides or back wall.

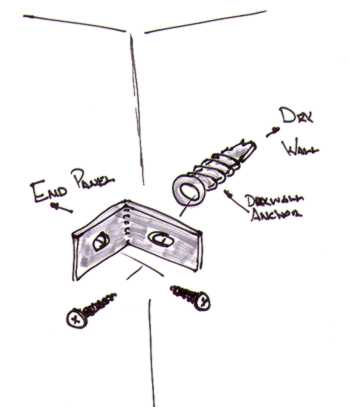

About the only way I've come up with to get the deed done involves using small metal angle brackets and drywall anchors (the wide threaded type that self-seat with a cordless drill). I've included some sketches of how I go about it, and I'm hoping to hear from others on better/different strategies for this painful chore.

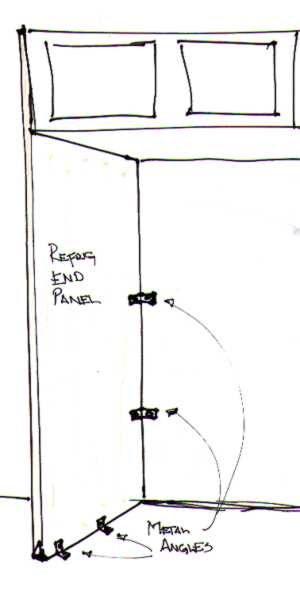

The first sketch illustrates the situation - the spacing of the metal angle brackets depends on the mood I'm in, but at minimum, I try for three on the bottom, and four up the wall.

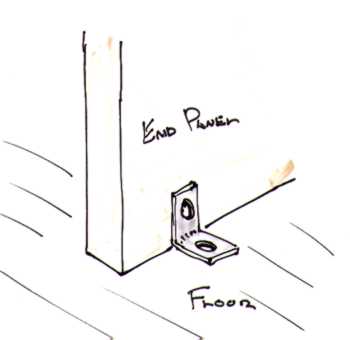

Fastening to the floor is pretty straightforward, unless it's tile, in which case I drill pilot holes through the tile with a hammer drill.

Fastening to the drywall isn't difficult, but I've found it goes *much* easier if I install the drywall anchors first, loosely fasten the angle bracket to the wall, put the panel in place, screw the angle bracket to the end panel, and then finish tightening the screw in the drywall anchor.

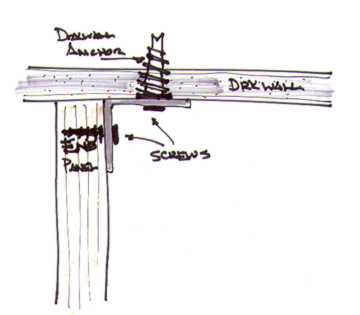

Here's a sectional view of the same area.

Forum Responses

I don't think there are many options here, especially if panels are only 3/4". If panels have face frame, we ring the inside of panel flush with face width, resulting in a cleat to attach to floor and wall. With 3/4" panels, we try and make panels 25" deep when possible (this works very well with full overlay), giving additional room at wall and pocket screw panels to floor.