Question

A few manufacturers have stated that I will not need a drill block because the time saved on the drilling and cutting is not worth the cost of the drill block. Only one has stated that as a panel processor, we will need it.

We process 60-80 sheets a week on the busy weeks and 20 on the slow weeks. My main goal is to take the cutting on the slider, dadoing on the table saw for the backs, and then the transfer and boring on the PTP to happen on the CNC in nest, and just bore the decks and top, bottoms on the horizontal drill.

I want to make the transition from screen to machine and I plan to use this for mainly processing case parts and smaller tops. Any advice?

Forum Responses

(CNC Forum)

From contributor L:

If you're doing normal nested based cabinet parts, I would highly recommend a drilling block. Our machine has a 9 head drilling block and sometimes I wish it was double. The drilling operations take longer than the cutting. For reference, we nest our drawer parts (3/4 mel) with the case parts and we're drilling for dowels. Also we're drilling for confirmats and 20mm drawer front adjusters. That's 4 drill sizes, so we go with 6-5mm, 1 each 7, 8 and 20mm drills.

Some manufacturers say you don't need the drill spindle and I found out sometimes it's because the particular machine model they offer you isn't designed to add an optional drill block without redesigning and increases the costs so much. Most of these machines are made as simple as possible. A drill spindle option costs around $10K. You'll probably never hear anyone that does cabinetry/closets using a nested base CNC say they regret having a drill spindle... Almost always the other way around. Also, if you ever want to sell your machine in the future, it is easier to find a buyer if your machine has a drill block - to other panel processors.

Yes, you can get a used separate line boring at $5K. Half the saving, but the time that the drill spindle saves on the machine would pay off in no time.

In a typical example, the actual drilling time for a wall cabinet and a base cabinet, including system holes, hinge holes on doors, and assembly holes for a blind dado style construction is about 2 minutes. The time to drill a hole and position to the next hole is about 1 second on average. The entire nest for two cabinets is just under 8 minutes. So if we add 2 minutes for loading and unloading then we can say the machine will produce 1 sheet every 10 minutes, floor to floor. So in an 8 hour work day a machine without a drill block would be 8(hours per day)*60(minutes per hour) = 480 (minutes per day) / 10 (minutes per sheet) = 48 sheets per day. Then using the 2 cabinets per sheet example, that would be ~96 cabinets per day.

A machine with a drill block would save some percentage of the two minutes that was spent drilling. It might be 20% or 30% but to be conservative letís say it saved 50% of the time, or 1 minute. That would make the time floor to floor 9 minutes. So 480 (minutes per day) / 9 (minutes per cycle) = 53 sheets per day or 106 cabinets per day. Thatís about 10% more.

But I think the real question is ďdo you need more than 48 sheets per day?Ē That sounds like a fair bit more than the 40-60 per week you need during your busy time. Iím not sure it would have any return to spend more on a machine with a drill block in order to sit idle more time. I think itís completely fair to say that a machine with a drill bank is more complicated. There are more extra air lines, solenoid valves, and mechanics. Even with a very good quality drill block, extra complexity will affect reliability. So thereís added cost and complexity but no extra return until you grow from 40-60 per week to 40-60 per day.

I don't believe you offer drill block as an option on your machine, do you? If you do, would you have to redesign the electronics/mechanics upfit on your machine? Or can you just replace the Z-axis plate and mount a drill spindle on it and everything would be working fine? I was looking at a machine similar to yours that uses Mach3 controller software (you use that too I believe) and wanted to add the drill spindle. The OEM told me that the machine was built as is for cost reasons, and they would have to do some custom works and upgrade the controller in order for Mach3 to be able to generate binary codes to call out the drills in combination - otherwise add more inputs and use one-shot M-codes to call each drill individually. I'm not sure if that's true or not, but that's what I was told.

I feel safe to say that over 90% of small businesses that own a CNC with the drill block, no matter what volume they do, that process panels with the 32mm system, would say they are glad they have it... versus ones that would say they regret having it.

If at least some owners that process panels with 32mm system on nested CNC routers with drill blocks say that they agree with you and they wish they didn't have the drill block, perhaps I can partially agree with you as well. When businesses invest in technology, they want to save time and ease of operations for the long term, to be able to do more and grow.

I'm not saying you're wrong or picking a fight with you, contributor T. It's just that after I talked to so many CNC owners and learned why different machines/oems offer different models and their sales pitches, I disagree with you.

If your friend is interested how the NEW CNC machine control interfaces with the drill block, I can explain it in detail to him. But simply stated, the NEW CNC machine control uses 2 PLCs (programmable logic controllers). Adding modular cards will create enough I/O (input/output) to control the drill block. The basic design of the electronics of the NEW CNC allows for essentially unlimited expandability of I/Os.

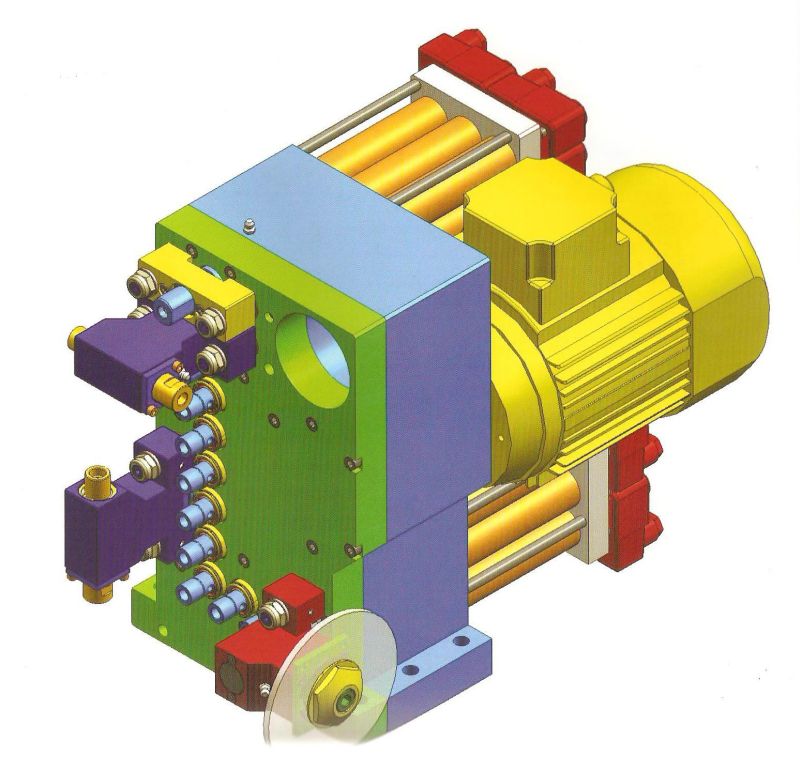

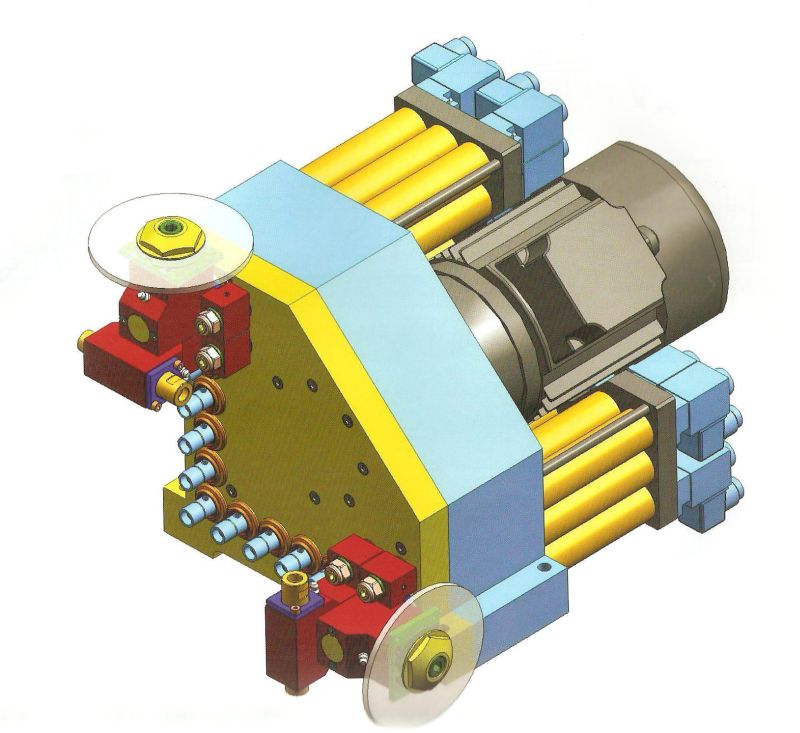

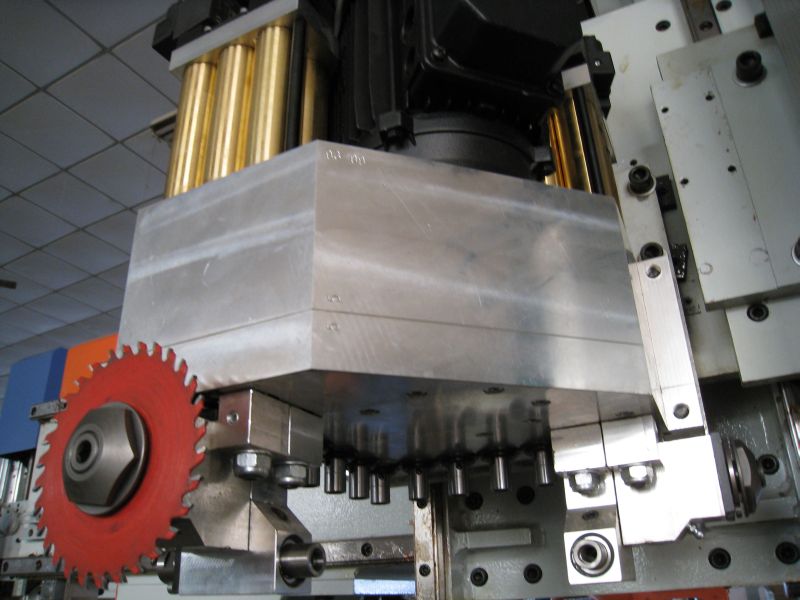

Attached below a drill block mounted to the spindle plate. The spindle mounting plate is made larger to accommodate the additional working units. The Z axis mechanism is quite different than a single head machine. We have a multi spindle menu on the web site that shows a few other examples.

The purpose of my simple calculation for capacity of a machine is a straight forward return on investment (ROI) calculation. Iím saying that from a dollars and cents perspective only, adding options to a machine that allow it to run faster, when itís under 20% utilized already, just does not pencil out. Companies do legitimately make decisions considering other factors (tangible and intangible) other than ROI. And Iím not saying there isnít a place where drill blocks are a great idea (I donít know the questioner's company's particular details). We have all seen many companies close under the weight of excessive overhead in the past few years. In the economy we all find ourselves working in, Iíd just lean conservative.

For about the same investment Iíd add the NEW CNC lathe option over the drill block. (See the lathe on NEWCNC.com). It adds a function that could use idle time on the machine to generate additional value.

Also, the programming/setting up for horizontal/saw operations on a flat bed nested machine would be very tedious - I've seen an OEM program/setup before - something I wouldn't want to go through.

Is your drill spindle showing a cartridge insert type - where if an operator bent one, a new one can be re-inserted so the drill block wouldn't have to be disassembled? I've seen one where a tech had to tear the whole aluminum drill spindle head to replace the new insert.

Large companies with large volume may benefit from these features, as they may produce the same parts day in, day out. But for smaller businesses doing custom works and changes almost every job, programming/setting up for horizontal drill and saw for every job would kill them. They'd be better off with manual equipment on work stations.

As for mach3, yes, that's what the OEM told me. You'd have to add more i/os, etc. too for the drill spindle on mach3. So how much does it cost to add a nine drill spindle on your machine?

The setup of any router tool, drill bit or aggregates is very much the same process. Tools are calibrated and offset values are entered (automatically) into the machine. Programming for router bits, drills and aggregates are handled in a straightforward manner by the CAM software. (Most all CAM software support horizontal boring tools.) Basically the software identifies the shape to be cut or hole to be drilled (vertical or horizontal) and outputs the code to use the appropriate tool.

This particular owner is in the high end architectural millwork business with about 6 employees. It is the nature of his business that his products and his processes are more highly customized. The justification of the horizontal boring attachment is the ability to complete the part on a single machine in a single machine cycle, and with the precision of a CNC. Also he recovers shop floor space previously occupied with a single purpose horizontal boring machine used only very little. The dado blade was needed for a certain product he makes similar to bead board. A multi tipped tool (like a dado blade) produced a much better finish, at a faster rate, than a router bit could. So for this owner the answer is yes, the drill block with horizontal boring and dado saws, fits the requirement. We offer this style of drill block to add maximum flexibility to the machine. But each case is different; we configure machines to match the requirements.

NEW CNC supplies 11 and 13 spindle drill blocks, when the application requires. (So far we havenít found a need for nine spindles that isnít easily satisfied by the larger drills.) Before I would quote you any prices, weíd need to talk about your requirements, but as a budget amount ~$6000 would add a drill block to a NEW CNC machine. Should a drill spindle need to be replaced, the process can be completed in about 30~40 minutes, with standard tools and without a technician.