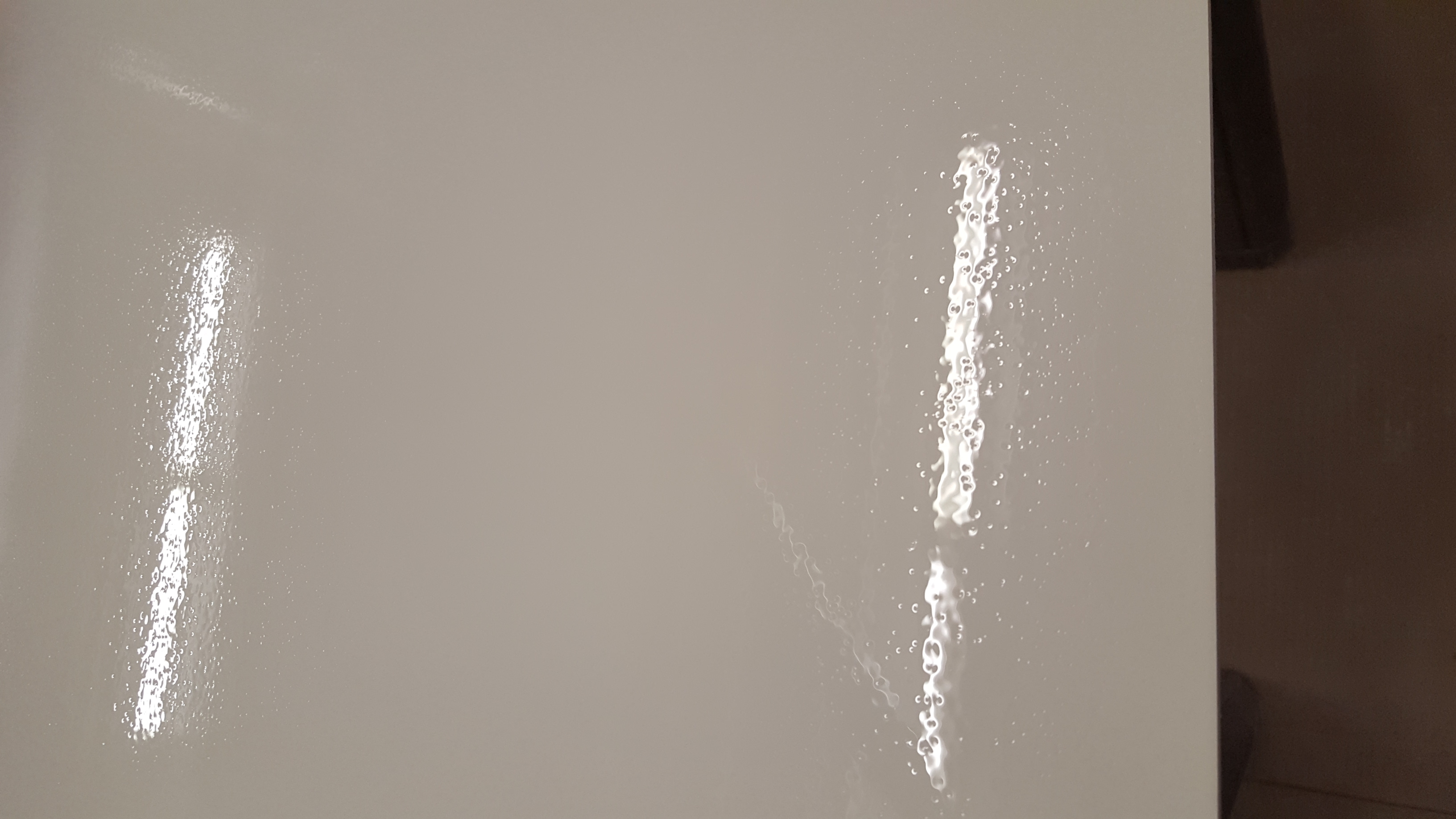

I just started using Kem aqua plus pigmented on a job and after spraying my second coat have pinholes forming (not fisheyes) that don't seem to want to level out. Any ideas or has anyone else seen this and figured out a cause and solution. Have a call into my rep but no response yet.

From contributor Ma

How thick are you spraying? That looks extremely thick but hard to tell from a photo.

From contributor Ro

What primer did you use? And, what sequence did you follow: Primer, wait 2 or three hours, sand completely (what grit?) and then topcoat?

Need more information.

From contributor Jo

Mark, it's about the recommended 4 mil wet. Any thinner and it doesn't flow. I'm surprised how fast this dries, much quicker than any other water based I've used. I did see my air supply was not as dry as should be, so I've drained, blown out and added new desiccant to that with some improvement. Also wondering about adding the R6K25 extender that is mentioned in the product lit. I also saw in another post that low humidity can cause issues and my shop is very dry right now.

From contributor Sh

Make sure you reduce with distilled water and not tap water..... I usually add Propylene Glycol 10-15% as a reducer/retarder... it has helped tremendous with kem aqua for me..... I'll tell you that thinner coats have the least problems to and with fairly high atomizing pressure

From contributor Jo

OK, primer was water base Bin as my SW primer order got held up for delivery and schedule couldn't wait. Dried overnight, sanded with 320, shot first coat of kemaqua at 5pm that day. Sanded w/ 320 this morning, everything looked great. 2nd coat started showing pinholes right away so I stopped. I suspected air contaminant so checked compressor and lines. I did drain some water from compressor and changed desiccant in dryer, blew air threw lines and used a new hose to aaa. This helped. I also tried thinning with 5% water but didn't seem to help any. I've played with air pressure and fluid pressure which also helped. I'm using a 313 tip on my CAT aaa, but SW rep suggested trying a 311 tip. I'll try that tonight.

Shane, do you get the Propylene Glycol from your SW dealer? The spec sheet says to use Butyl Cellosolve, but not sure about quick availability.

From contributor Ni

I've had that exact same issue this summer. a average summer day where I live is 90+ with 20% humidity and it was drying faster then the products ability to flow out...or so l guessed. Now with temps down and humidity up in my neck of the woods the issue the issue has disappeared...for now. I found a through scuff between coats helped some but didn't stop it. I suspect Shane has the answer.

I get a product from SW called M-1 latex paint flow enhancer, it contains mostly propolyene gylcol with some other ingredients, that just might do the trick.

From contributor Jo

Thanks for all the info Nick. Tried my 311 tip tonight and must be it didn't get cleaned good enough by whoever used last..... no flow at all. Just ordered a new one. I'll see about the flow material.

From contributor Da

That is why I won't use WB. Try real lacquer like resistant.

From contributor Jo

John B

The 313 tip was far to big. I have sprayed waterborne for 10 years. I use a CAT AAA. I suggest you get a tip that has the pre-atomizer in it. CAT refers to them as a F tip. Different as night and day.

I use MLC Aqualente now, but I have used others. All spray much better if thinned to 35 to 45 through a Ford cup. Also I have found that the 409F tip works best.

No air movement across the item until the finish has skinned first.

From contributor De

I sprayed KemAqua for the first time this week after years of gf poly and aqualente. I had lots of issues with flow out and runs using a Merkur AAA and .411 tip. I sprayed the cabinet doors hanging with the fascap door hanging clips so I could spray both sides and by the time I got it so it would flow it would get runs. I ended up turning up the air pressure and down the fluid pressure from where I normally set them for WB finishes and that helped but obviously left me with less build per coat. That being said it did lay down flat and looked very good.

The primer they sent me is their WB surfacer and it's really thin as well. I'm not as impressed with it and would like another option.

From contributor De

I have been playing with their water based surfacer and Kem Aqua pigmented topcoat and to me they are not very good products to spray on site which is common for me.

I was getting looks like that from my AAA that was set up to spray general finishes products and when I sprayed vertical surfaces I could not get it to lay flat or avoid runs. I ended up dropping the pump pressure about 20 percent and increasing the air pressure about the same. This helped but still gives too many runs on overlaps that I never have to worry about with other products.

I talked to the rep and his answer was that it is a production finish and not geared for what I do. I will say it looks fantastic on things I spray laying flat but I might be too old to want to go through the learning curve and will go back to general finishes.

From contributor Ni

I've found Kem-Aqua is a lot more user friendly when using a pot/gun set-up as opposed to a pump. In the shop I've been spraying the clear and pigmented with either a Sata 1000k 1.3 needle/nozzle connected to a stainless steel pot or a Devilbiss Compact gravity gun with a 1.3 for the clear and a 1.4 for the pigmented. On site I've been using a 4 stage turbine connected to a Accuspray 10 gun with a 1.3 nozzle for both the clear and pigmented and getting very good results.

I should also add I am not a WB only shop so for clears when in the shop l spray a coat of SW vinyl sealer on first and this really improves the look and feel of the Kem-Aqua finish coats. For the pigmented in the shop l use either Bin pigmented shellac or Kem-Var CV primer/surfacer, both of these products will give you a ideal surface for your top coats.

On-site in a occupied home, l'll brush on the bin shellac on any mdf then spray on the WB primer/surfacer. I don't get quite as good results this way but still very acceptable.

From contributor De

Good info Nick. I have a turbine with a 10 gp gun that I tried but I believe the tip size I am running is bigger. I will give that a shot.

From contributor Jo

When I used to experience pins holes the cause was off gassing from the previous coat. So if you sanded/scuff sanded prior the final coat (you should be for the proper mechanical bond) then that "dry" surface is now re-expose and needs to dry a bit further before you cover it again with more wet product. So sand everything put it back on the drying rack and get some air movement going.

From contributor ni

John, thankfully that's not what's going on here...it really is a flow/surface tension issue and not a micro-bubble/off gas issue and once again, Shane has the answer; light, thin coats and if that doesn't work add some propylene glycol also a good even scuff between coats helps too.