Question

I am new to the industry and have been researching machines, software, etc. Something that came up in a discussion was the life expectancy of the bearings in spindles. I was told they need replacement after about 2000 hours of run time and it doesn't matter if air cooled, liquid cooled or what brand. They are all about the same. Does this sound right? How long does this take for turn around? How much does this cost? How do you normally do this, get a rebuilt spindle and swap them out? How does an ATC affect this process?

Forum Responses

(CNC Forum)

From contributor C:

Does this sound right? Run the spindle until it fails as the repair facilities that I have had dealing with will generally tell you there is no magic number of hours that a spindle must be rebuilt. I have seen some run a matter of a couple of years, and some that are almost a decade old and these are both the old metal bearing and the ceramics. I have had dealing with Omlat, Eurospindle, HSD, and various others and I can tell you, most customers will run the spindles until they fail. Very few will pull them out of service on a timetable.

How long does this take for turn around? Turnaround time is up to you. If you are willing to pay you can have some of these turn around in a matter of one-two days, if all parts are in stock.

How much does this cost? Average cost seems to be about $2500-$3500 but this is going to be dependent on the HP of your spindle, there are some of the lower, smaller HP spindles and it is easier to just by another one.

How do you normally do this, get a rebuilt spindle and swap them out? There is nothing wrong with a rebuilt spindle, and in some cases you don't have a choice, there are holdups because of parts not being available so you might have to get a rebuilt. Just make sure there is a warranty for the spindle and you should be fine.

How does an ATC effect this process? None of these choices will affect your ATC, if all is connected correctly

Keep in mind that you lose about 15-20% of your power when you change the direction of the output rotation, (a 90 degree aggregate changes from perpendicular to horizontal output). Having said that, bigger is better when you know what your production demands are for the future and can plan accordingly.

The warm up time varies according to the spindle you have, etc. Usually just getting the spindle up to temperature prior to running is what you need. This will get the lubrication warmed up and able to flow around the bearings prior to machining. You can really just let the spindle spin for approximately two-five minutes to help with this.

The strategy to dissipate the heat is one of the primary design differences in spindles. Itís crucial to bearing longevity to remove heat. Air cooled spindles commonly use an aluminum motor casings utilizing aluminumsí thermal conduction properties. Itís also common to use a fan to circulate air past the spindle. By contrast liquid cooled spindles recirculate coolant thru ports in the spindle body. The better quality liquid cooled spindles actually chill the liquid to contribute the cooling properties.

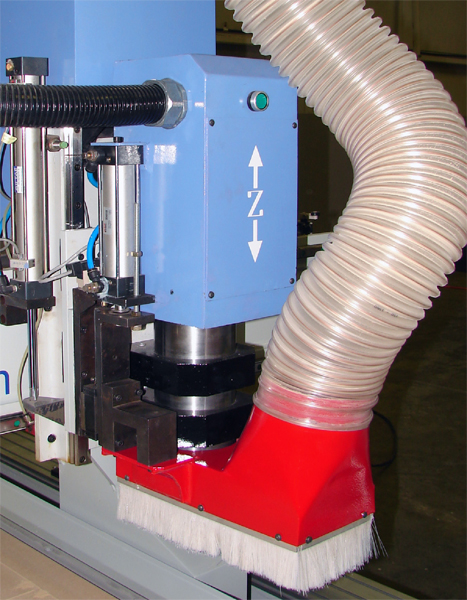

Depending on whose calculations you use keeping the bearings actively chilled with liquid cooling will extend the life of the bearings three to five times. Itís common to have 10,000 hours on a liquid cooled spindle. Below is a picture of the NEW CNC 7 HP spindle and chiller. The other benefit of liquid cooling is power of the spindle. Itís common that an air cooled spindle will lose more than 40% of the power when itís in continuous use. A liquid cooled spindle will not see a power loss because the operation temperature is constant.

** NEEDS IMAGE WORK **

http://www.woodweb.com/images_forums_public/cnc/Spindle.jpg

http://www.woodweb.com/images_forums_public/cnc/chiller_1.jpg

** NEEDS IMAGE WORK **

1. Filters on the cooling coil packed with material.

2. Haven't checked the fluid level in months.

3. Not checking that you even have cooling water flow in to your chiller.

4. Yes, you have to flush and change the cooling medium. It gets old just like your car antifreeze does.

5. Oh and the best one, I didn't know it had a spindle chiller, is that what that is back there.

Yes the last one actually happened. My preference is air cooled, just because so many people forget about the chiller maintenance.

When it rises more than two degrees above the set temperature two things happen. First the chiller unit sound an alarm, second a screen pop up on the control with instructions (text, pictures and a video) for how to clean the filters. The machine will continue running the program in progress but will disallow another cycle until the alarm is cleared.

We also monitor the flow of liquid. Should the coolant level drop enough to limit the pressure in the system, both an alarm on the chiller and a pop up instruction to clear the alarm will occur. As a side note we also monitor the load and temperature of the spindle.

We do recommend that you change the fluid every 10,000 hours of operation. Here again we have the control keep track of the hours, and signal when it needs to be replaced. Itís true that owners forget that there is a chiller back there, but thatís how itís designed.

I marked the BT holder and the bottom of the spindle before I started the process once finished the marks were no longer lined up the BT holder spun inside the spindle about 22 degrees. However it's possible that it rotated 22000 there is really no way of determining how many revolutions it made while machining this simple 12" x 12" x 3/4" part. Now because the BT tool holder is spinning in the spindle when the machine goes to tool change it causes the tool changer to hang up.

From my experience metal rubbing against metal causes friction which creates metal dust. This metal dust is enough to stop the draw bar which lightly taps the BTís retention know along with a blast of air to release the to its storage position. I was told that the way around this was to adjust the spindle chillers temp that could be as tight as up to a four decimal place increment and that ambient temp has nothing to do with it. Which is great considering my shop is located in Phoenix, AZ and the temp in my shop can swing 30 degrees within the same day.