Question

I am switching my cabinet production to dowels. Iím looking for a horizontal/vertical construction borer in the 32 mm system. I already have a Ritter 46 to do my regular line boring, so itís a dedicated dowel boring unit I need. I looked at so many brands and deals, new and used these last few days, that I canít make up my mind whatís best. Hope on buying used for 4-5K up to new for 6-7K if itís worth it. Any suggestions?

Forum Responses

(Cabinetmaking Forum)

From contributor A:

I bought a used Ayen SKB-23 at auction for about $700. We put about 400 into parts to get it in good working order. Ayens are no longer made, but we paid about 8k for our first Ayen in about 87, and we sold it in the early 90's for about $7500. There are some very good deals at the online auctions these days if you are capable of repairs in house.

Dowelling borers do not need bells and whistles. The fences will be set and never moved. The only adjustment that will change on a job to job basis is the material thickness, so that should have a mechanical digital indicator (not necessarily LCD). I also do not think quick change chucks are necessary. You should be able to come up with a boring pattern that will work on all your standard depths without bit changes.

One accessory that is nice is the center-mounted miter and 90 degree fences. They usually drop into pin holes in the center of the table and automatically align. With these you can bore rails and stiles regardless of the length because the normal fences are removed. Usually the problem when referencing a long part is that the opposite fence needs to be removed so the part can hang off the table. Then the fence must be remounted to bore the opposite side of the part. The center mounted fences eliminate this problem. Boring machines are extremely versatile. I use mine for all kinds of tasks. It is like when you bought your first Kreg jig and found uses for it every day. Except a dowelling machine is a lot faster.

If your shop is busy enough to not be able to wait for the flip top mechanism to reset (10 or 15 seconds) or if you are likely to wear it out in a year of two, you should look at a dowel boring/inserting machine. These machines usually only bore horizontal and they squirt glue in the holes before inserting the dowels (some also have vertical heads and there are CNC versions that do all operations with one traversing head). This makes a huge difference in assembly. It takes us two minutes to glue and insert the dowels during assembly. I would not buy a CNC dowel inserter because they cost more, are slower and are much more complex and likely to break down. The standard machines have several dedicated bore/dowel insert heads that are easily adjustable. But, as I said before, they should not require any adjustments if you plan your doweling patterns intelligently. Most shops either use a CNC or point-to-point for the face boring if they are that busy.

I am happy with my flip top style machine. I believe the dual head machines all drill from the top. This leaves the holes full of dust. Also two heads means double the amount of drill bits, two pneumatic cylinders, two electric motors and associated switching. Basically it is twice as likely to fail.

Dialing in a flip-top machine is a super pain in the butt. Fortunately mine came perfectly aligned from the factory. Hopefully yours will too. After the bushings wear out and require replacing there will be some work involved for sure. But I am guessing the motors, cylinders, switches and other parts will wear out first!

I believe the Maggi machines are better than the Griggio. Maggi really specializes in boring.

What the previous poster said is important. Make sure your deepest cabinets will fit between the left and right fences. The specs do not usually explain this very well. It is safest to assume the width between the first and last spindle is the max. All the machines I have seen only allowed the fences to be positioned around 32mm past the first chuck.

Do not try to use a construction boring machine for line boring. It is a real headache. I wish I had a proper line boring machine, but I am waiting to buy a CNC boring machine.

Per previous posters, ignore the bells and whistles on these machines. Set it up once, then don't touch it. A mechanical digital indicator is just an invitation to fool around with the settings. I literally haven't touched my settings in five years. A 21-spindle gives you 27"+ working space, assuming 32mm setback from the panel face to the center of the first hole.

Contributor P, do you not reset the material thickness setting based on the material? I know that theoretically it does not matter; as long as the part orientation is maintained the off-centeredness of the holes will match. But mistakes happen and there are odd situations were maintaining part orientation is not practical. In these cases, is it good to have the material thickness dialed in, or do you really never have an issue with this?

How do you deal with the different thickness in 3/4 panels? I have variations from 18 to 19mm in what I use. Does the "keeping parts oriented" come natural, or is it a constant struggle to figure what side is up?

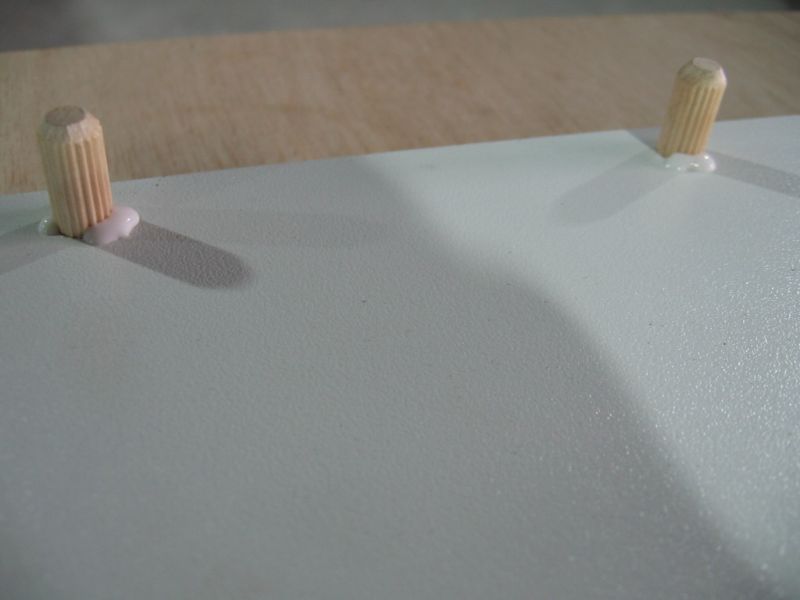

When you get your machine you have to go over all the alignments, especially the head to deck alignment. Use a good caliper. To set the left and right fences you get a piece of hardwood, say 8" long x 1 x 3". Drill into the end grain on the right fence and without flipping the wood, slide it over to the left fence and drill a hole. You will see the vertical difference, if there is one, due to head alignment. To set the distance on the left/right to the side fence, take the same size of wood, drill into the end grain on the right, and then flip the wood over and drill into the end grain on the left. You will see two holes one on top of the other and they should be in exactly the same vertical line.

I think all horiz/vert construction boring machines have an offset for the depth between the vert and horiz positions. My machines are 7mm. Meaning they bore 7mm deeper in the horiz position than the vert position.

Theoretically you can use 35mm dowels in 18mm or 3/4" material. Practically speaking this is cutting it a little too close. The vertical boring (face holes) ends up being very close to the thickness of the panel. Every once in a while we would have a dowel blow through the side, or cause a bump/cracked melamine surface, during assembly. This happened because the holes were not deep enough. When the operator has to bore hundreds of panels in a shift, there is bound to be a few mistakes.

So we use 30mm dowels, which seems to be the industry standard anyway. I liked the 35mm dowels because they did hold a little tighter and practically eliminated the need for clamping.

As for clamping, we produce 5 to 20 completed assemblies a shift and we only use ordinary screw-bar clamps. After using rubber mallets to assemble the cases, we put two clamps for each doweled part (top, deck, and any fixed shelves on tall cabinets). Then square the cases using large shop-made squares and hot glue the backs into their grooves. This locks the case square. The clamps stay on until the next case is assembled and needs to be clamped, usually 10 or 15 minutes. A case clamp would speed up the processes, but not because of the clamping time specifically as much as its effect on the whole process. There would be no whacking with mallets, no checking the case for squareness (this requires walking around the work bench), applying/removing clamps, and all hot gluing would take place in one spot, allowing us to use a higher capacity glue gun like the 3M systems. But for now it is not an issue.

This look at a case clamp vs. using bar clamps is a great example of lean thinking. If you only look at the case clamp as a replacement for bar clamps, it does not make sense. But if you consider the implications the case clamp has on the entire production flow, you will see there is a big potential for eliminating non-value added work. The same is true of using dowel assembly vs. dado or nail and glue.

Did you get the 1500 and the 3000 fence to go with the machine for line boring? Another thing I noticed is when I got the machine, the chucks had a bit of rust or gunk buildup on the inside which made them very difficult to remove or put on. After a good cleaning and a bit of polishing, they slip on nicely. Get an extra set of chucks for the 8mm bits. I think I have 8 red and 8 black 8mm bits and the full set of 5mm bits.

I was thinking to use regular fluted dowels and put glue before inserting. Is there an easy, quick applicator to properly dose this?

This brings up another tip - when horizontal boring, always slide the depth stop (the one used to gauge the thickness during vertical boring) to the center of the panel being bored. This splits the difference of the out-of-squareness for the panel.

For applying glue I use a rubber squeeze bottle with a dowel hole attachment. I think I bought them from woodworkerssupply.com but I did not see them when I did a quick look just now. Lamello makes a very nice metered dowel glue bottle but it is $100! The rubber bulb type that we use is easy to accurately dose.

Do you have a special setup, layout or jig to put your case clamps? There has to be a more productive way than getting 8 clamps out from a big pile with long bars sticking out and going around trying to hold a piece of scrap between not to damage the case while tightening each clamp to full strength in 2 or 3 stages. Is there a way one person can do it and look like he has a productive procedure?

Pre-glued dowels with a sprits of water are really fast and easy. Now and then I have to use unglued, and they're much slower. Lamello's Dosicol glue-metering bottle is great, but gets gummed up easily, and is a bitch to clean. The Minicol lacks metering, but is quick and low-maintenance.

As for the clamps. Each assembly table only has 4 or 6 30" clamps. The clamps are never in a pile. They are stored under the work table until the first cabinet is clamped. After that the assembler moves the clamps from one box onto the next completed assembly as needed, one at a time. The clamps are not returned to the rack (under the assembly table) until all cabinets are assembled. After the clamps are removed from the previous cabinet, the worker puts on corner protectors, wraps it up, and puts it in the "to be picked up" area, which is immediately adjacent to the assembly area. If we are in full tilt assembly mode, there are three assemblers and one person dedicated to prepping for shipping. There are longer clamps on a rack central to all the assembly tables for wider cabinets as well as other odd tools needed infrequently for assembly and glue and dowels for refilling the assembly tables supply.

You should not need cauls or 8 clamps, nor is there "3 stages of tightening the clamps." This is the beauty of dowels. You can not overtighten the clamps, it is not possible to squeeze out the glue. We apply two clamps to each horizontal member; one at the front and one at the back. If your dowels are the right diameter, the clamps are practically unnecessary as the cases will stay tight after whacking with a mallet. You should not need to worry about damaging the sides, as they are not visible. And if your clamps are damaging the sides, there is something else wrong with your clamps or material. We use melamine on most of our cases, but even cheap plywood is not dented from our clamping.

All of the things I am saying are dependent on flat and square parts. Warped, out of square parts will not allow the quick clamp times and will be a pain to assemble. Also if you are using face frames, the assembly process will be different, as more clamps will be needed. A case clamp is pointless for face frame cabinets. You cannot clamp the face frame while it is in the case clamp and you will have to wait for the glue to dry on the face frame to case joint, unless you use pocket screws (that is a whole other story).

I'm comfortable that my Altendorf will get the panels square and straight. Just a bit worried because we often do plywood boxes, and plywood is never really flat. As the system of squareness requires two parts, the box and the door, I'll start working from the other side first. I'll look for an (inexpensive) door clamp to make sure door assembly is square.

If only I could find the pneumatic clamps used on these door clamps, I would build the table myself. So many pistons, so many specs, no idea what I'm looking for.

In our shop, all parts flow from saw to assembly continuously and are grouped by the cabinet from the beginning. After boring operations are complete, there is a pile of parts that contains all the parts for one cabinet and the assembly sheet. Cabinet backs and doors are cut earlier and kept in a rack next to the assembly area. So an assembler grabs the sides (always on top of the pile) and mounts all hardware, including feet. Then he knocks the box together, clamps it, hot glues the back, mounts the door, and drawers (drawers are assembled as needed, parts are either on the job rack or with the case parts depending on the thicknesses), tapes the needed shelf pins to the inside of the box, puts the adjustable shelves in the bottom of the box, and then grabs the next pile of parts and does it again. After the second box is clamped (using the clamps from the previous box), he adds corner protectors, skids (usually not needed) and wraps the whole assembly up with the assembly sheet showing. All parts are also accounted for before packing. The case is then moved to the pick up area.

So to answer your question, it takes one person 10 minutes to assemble a simple upper cabinet and 25 minutes to assemble a complicated tall wardrobe cabinet with lots of drawers or a clipped corner cab with 90 degree doors. This includes packing and moving the assembly.

Adding people changes the timing and we practice the Lean, Flow production based, cellular system using floating workers. This means that workers automatically move up or downstream to alleviate log jams. The panel saw operators will help the edgeband guy, the assemblers will help the boring operator, etc. When we are busy it is pure beauty to see everything and everyone moving seamlessly. Because boring is our usual bottleneck, it is common to see 3 people operating those machines and no one running the saw. I have taped a fuzzy stuffed animal to parts and watched it move around the shop (our layout is circular) until it ends up in the pick up area. Simple assemblies are completed in as little as 20 minutes, and if we are fully staffed, assemblies are finished every 15 minutes. These numbers hold more-or-less true even for odd custom work. We recently did 25 beds for a commercial job in two days with 6 workers. As far as the workers are concerned, it is all the same.

I will typically band the bottom edges of my upper cabinets as well as the shelves with a white or hard rock tape depending on if the case is white or hardrock. The face edges of the cabinet are banded with a tape that will match the door colour.

Now how do you deal with this?

1) Only band with tape to match cabinets and ignore matching the doors?

2) Don't band the bottom of the uppers and then do all the shelves as a batch?

3) Change tape in the bander every couple of minutes?

4) Two banders set up?

5) Other?

Let's say all exterior banding (matching the door) is done first for a given cabinet, the operator then switches to white for interior parts and does all of those. For the second cabinet he does the white first (it is already loaded), then the exterior color. We use 1mm tape for everything except doors, so there are no changes to the settings on the machine - just pull the tape and stick the new tape in the hole.

Because the parts do not come off the saw in exactly complete single cabinets, the edgeband operator sometimes groups parts more on a given quantity than a specific assembly. Example: he will do the white edging for 10 parts, then do the exterior edging on those parts and continue the exterior banding on the next 10 parts. Then the parts are sorted as they come off the bander, which is the easiest time anyway. (Cabinet Vision has a setting for how much overlap/mixing of parts in the saw optimization. This improves the yield tremendously. We keep it at 3 sheets, meaning all the parts for a given cabinet must be contained within 3 consecutive sheets.)

This might sound like a lot of work, but it saves a lot of work as well. This is a great example of batching vs. flowing with quick setups. If all we were doing was edgebanding parts, it would definitely be a lot faster to batch the like parts. But we are making cabinets, and the banding process has to be viewed in context with the entire process from design to delivery.

Our flowing process falls apart if we have less than 3 people manning the case-work cell. Even with 3 people, it is hard to not be upset knowing how fast it goes with seven people.

But the important thing is value added work. Even if the saw operator is pulling double duty with the edgebander, and the boring machine operator is also pulling triple duty with the edgebander and the assembly, the effect is that everyone is doing real value added work the whole time. No one is wasting time with sorting piles for batching, or waiting for a large batch to clear the bander so they can start assembling. Everyone is actually truly building cabinets the whole time. This is a big deal. There are still a lot of lean improvements we can do. I would love to have an edgebander that can feed two different tapes at the same time. That is available for my machine as well. But the cost is not worth it. Buying a CNC boring machine would be the biggest improvement we could make now. That would make the boring operation as simple as operating an edgebander. And allow any employee to run that station, meaning any assembler could run the boring operation. We could practically eliminate that position. Or at least the boring operator would find himself helping with assembly or banding more than drilling holes.

Clamping is required, but it does not serve the same purpose as when clamping glues dados or butt joints. In dowel joinery, clamping is only needed to close the gap while the dowels are locking in place. They lock in place because of the swelling effect. As for case squareness, the only way to ensure a case stays square is to glue or staple the back. Most Euro box cabinet shops use some form of quick setting hot glue to do this.

When I talk about not needing clamps, this is under certain conditions when the cases are holding tight with just the initial friction of the dowels securing the parts together. No one would recommend not clamping the cases for at least 50 or 10 minutes. But many of us do it anyway... Experience will help you see what I mean.

The big thing about clamping dowel cases is you do not need the massive pile of clamps usually associated with case assembly. One set of clamps per assembler is plenty. If you are attaching a face frame, things will be different. I have been using biscuit type joints on the rails only. This allows us to adjust the face frame left to right. Doweling is not practical. Pocket screws are ideal if you can use them.