Question

I occasionally make glass doors with mullions-they are a real pain-I've tried making a wide part and the ripping the excess out of the middle and gluing the pieces together and gigs to machine the part at correct size, neither way is as safe as I would like. Someone must have a better way. Is there a special machine that can do this? Any suggestions would be appreciated.

Forum Responses

(Cabinetmaking Forum)

From contributor A:

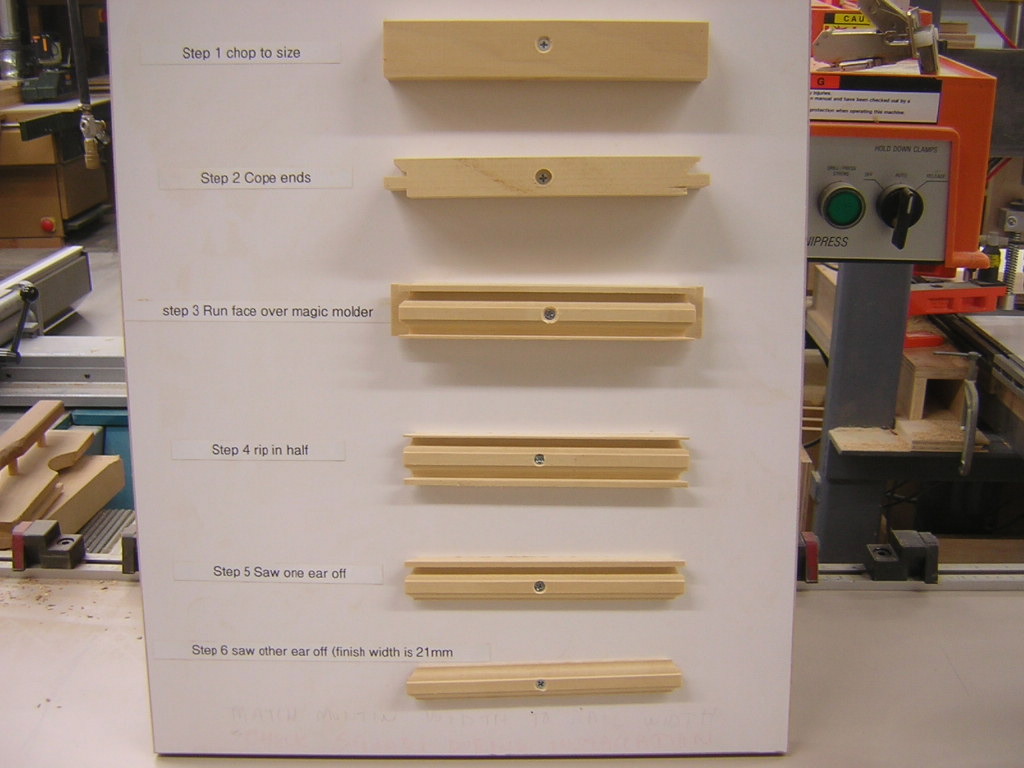

We build doors like this from time to time and our labor to produce a door is now about 25% of what it was when we first made them.We cope and stick all of our doors with Leitz insert tooling. We had LRH Tooling Company produce magic molder inserts that mirror the profile of the various stick patterns we use. The process is fairly straightforward but it helps a lot to get the sequences in the right order. We made the storyboard you see as a way to get these processes straight in our own head, as well as provide a training tool to make others more proficient. The magic molder insert costs about $100. The storyboard method of training is priceless.

The secret - use a shim the same thickness as your glass profile on the outfeed side of the shaper fence. Add the same thickness shim to the Off Fence when running the second side. This is the only way I can get parallel parts. We cope after sticking by using a backer on the tenoner made with the tenon knives. I do think that a set of knives for the Williams & Hussey would be as good as a Sticking Machine as in window shops. I intend to do this as soon as I make some money on a job. Anyway, the molder would allow you to make different width muntins. Some of my door customers want 1/4" between the glass, but I prefer 1/2". On the molder, make a jig to hold the part on the second pass by using your coping knives. I use the Bostik table lube to make thing slip along. Wax is OK but may screw up a finishing job.