Hello all,

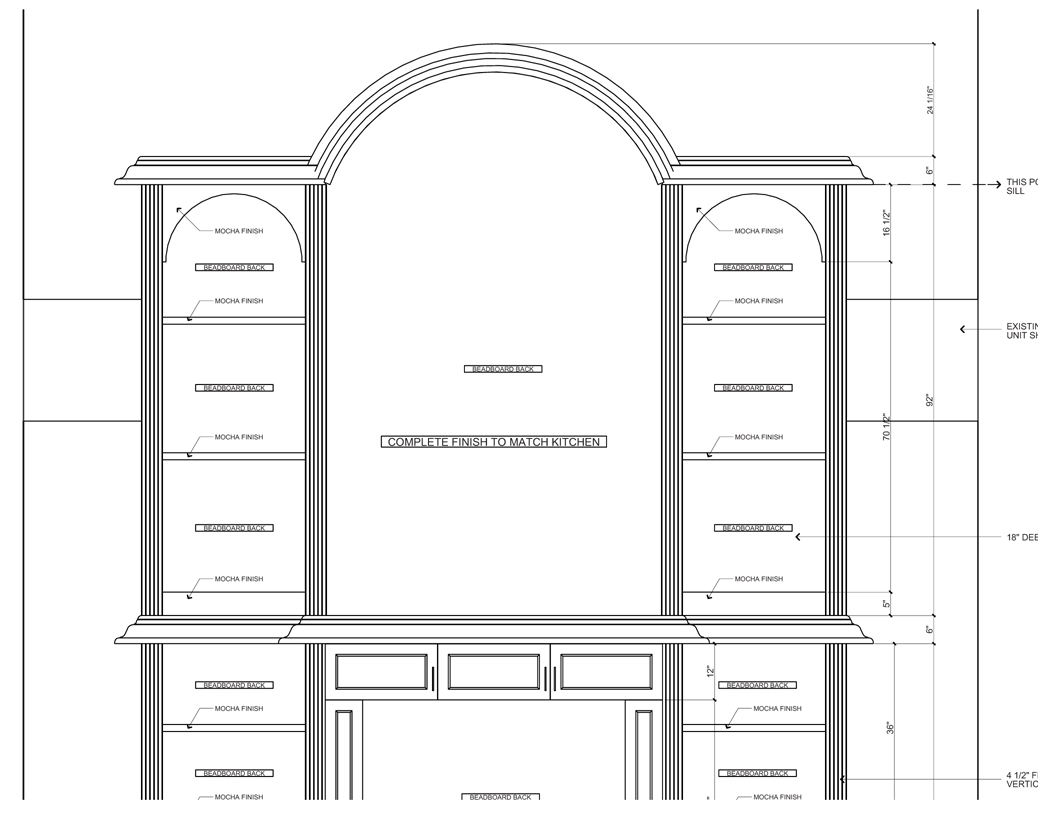

Please take a look at the attached image. Can any of you provide suggestions on where I can source the "upside down" looking crown molding?

Is it even possible?

Any help would be much appreciated.

From contributor pe

You could make it on a pin router or router table. Could get cutters from Eagle America. com.

From contributor Jo

I believe from what I'm seeing the with the execption of the center this is normal crown just applied upside down. The radius work could be done on a williams hussey with the same knives and a radius jig wether they're suppose to match or not, I'm not sure what the center is from the design the profile lines don't match anything. I guess it wouldnt have to be the same as long as the depth of the moulding would be the same or returned to the center. Hope this helps!

From contributor Ji

Is it possible? As far as I can guess...Yes. The reason that it looks impossible is that the architect hasn't taken the time to draw it correctly. (If the architect can't draw it how does he expect someone to build it?)

Go back to the guy and tell him:

1. The crown molding at the top is definitely up-side-down and goofy looking (that's putting it mildly).

2. The use of the same up-side-down crown on the lower unit is even goofier.

3. Ask for a proper detail showing the upper radius molding intersecting with the level straight. If he can draw it for you, you'll discover (among other things) required radial miter joints.

I'm being sarcastic but I'm truly wondering if this was done intentionally. It looks to me as if some kid drew this. As a professional woodworker, the completed unit would be an embarrassment to me.

.

From contributor D

The lower counter top molded edge by itself looks o.k. can't really see the detail but the scale looks right . Looks like they just carried the same detail to the crown.

Like they tried to create a soffit type of crown but agreed it looks wrong.

From contributor ay

Eagle America is a good option. you will find valuable info there.

From contributor Da

Jim is right, and he is being kind. That is a laughable design. "Hey look, no one has ever done this before!" And there is a reason....

Once the upper curve molding meets the horizontal at 90 degrees, the miter will be simpler. Apparently even the draftsman could not get it right.

From contributor Je

First off that's a 6" tall crown....forget about using router bits to run it!

Second as the others said it's poor design at best and really IMHO will look much worse when finished than it does on paper. Using an upside down 6" crown as the transition from bottom to top is going to be truly unimpressive....again IMHO.

good luck,

JeffD

From contributor Fa

I think I will ask the client or suggest to the client that we replace the existing design with a regular "upright" type of molding.

Thanks for the responses.

From contributor Da

I do not know why it would be drawn like it is - perhaps there is some good logical reason for it to be that way. I would ask the designer why they bucked about 2500 years of precedent.....

I have found that if things don't look right - follow convention or precedent - then they just don't look right. Often people will not mention it, feeling they do not have the design knowledge or confidence to say - "It isn't right". But they still don't like it as much as they would were it 'right'. They most often can't even articulate what it is that is off, just that something is not quite right.

Ill proportioned things also fit into this category - they just don't look right, though it may not be apparent just what the problem is.

From contributor D

Looks like the base is a block front the middle section is deeper , maybe the top section is also .

I can't tell if the arch crown is the same detail but if it is or isn't once you flip it the right way and if the center sticks out a bit further, miter it and return to the inside miter of the crown on the ends.If it is a different detail I would scribe the main crown to fit against the arch detail or ? , .

From contributor ma

For the bar-height counter, just use crown upside down. For the 12'-14' height upper bit, use a 3" board sticking out from the face of the piece, and tell them that there's upside down crown above that.

From contributor Ed

Farrell,

While I agree with a lot of the post that the design is strange, if that's what they want, that's what they get to pay for. If you want send me a drawing of the profile & I will get you a price. As far as mitering an elevation radius into a horizontal run, if you know what your doing it's a major pain but not impossible.

Plus it looks a lot better than both pcs. hitting a square block.

Thanks

Ed

From contributor Mi

The curved section looks like a job for CNC. Keep in mind too that assuming you can get it made up, the miter where curve meets straight isn't a straight cut that you could do on a chop saw, but rather a slight ellipse.

Making it straight usually isn't noticeable when it's a smaller profile, but it's a different story with something as large as 6".

Oh, and you've gotta love the 12" high X what looks like 24" wide doors.

Yeah... those won't sag.... riiiiiight