Question

We want to start machining paint grade doors out of 3/4" MDF on our flat table CNC. Nowadays for our shop most doors are flat panel. How good of a finish will the CNC leave on the panel surfaces? Will there be much sanding needed?

If we remove the material on the face of the door to create a flat panel look but do not remove anything on the back of the "panel" will this create an imbalance and cause the door to warp? Will the newly machined surfaces need any special attention when finishing? Is there a type of MDF that machines better or accepts paint (tinted conversion varnish) better?

Forum Responses

(CNC Forum)

From contributor K:

It all depends on the quality of the MDF. Plum Creek mills real nice but the material you get from some suppliers will cause all kinds of problems.

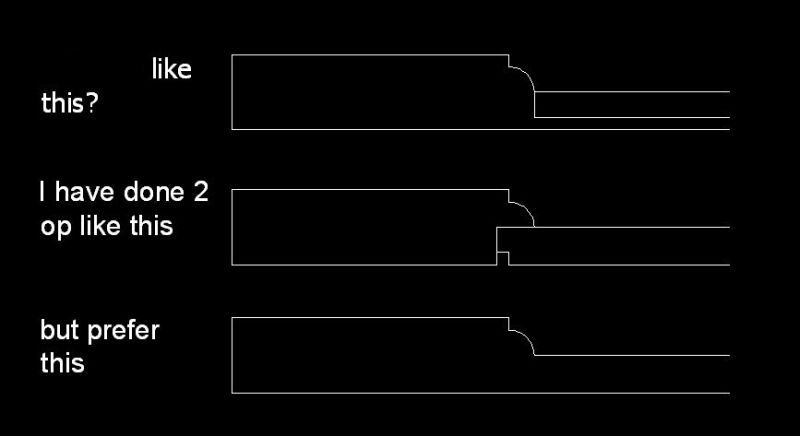

You can do all kinds of profiling and be successful with flat panels too. There is a school of thought that using a 3/8 or 1/4 panel inset into the back of a 3/4 thick frame saves time in finishing. I have done both successfully but generally prefer a one piece arrangement.

I now prefer a one-step deal on the router though with good material. You never completely get around sanding of course, and the open areas look best with two coats of primer, but you have to do the profiles anyway, and they come off the CNC with any profile you like in one shot whether you have point to point or nested base. The biggest issue with flat panels this way is really good Z registration between tools. You can't have the tool cleaning up the corners at a different level than the one hogging out the fields. Just be careful with measuring your tools and it is fine.

To the original questioner: Yes like the top one in your drawing. It also works well when the sticking profile is square. In the profile you are showing, I would use a 3/8" ovolo cutter followed by a pointed roundover that has the same radius as the ovolo. This will minimize the corner radius. I would then use a 1/8" straight bit to follow the top square shoulder. This will leave a tight corner that emulates conventional cope and stick. My last op would be the pocketing of the panel area. If the sticking is square you can chuck up a 1/16" drill bit and drill out the corners of the panel pocket and then run your other cuts. MSC sells collets for almost any size drill bit. I prefer to use the router to drill with when accuracy is a must.