Managing Battery Drills

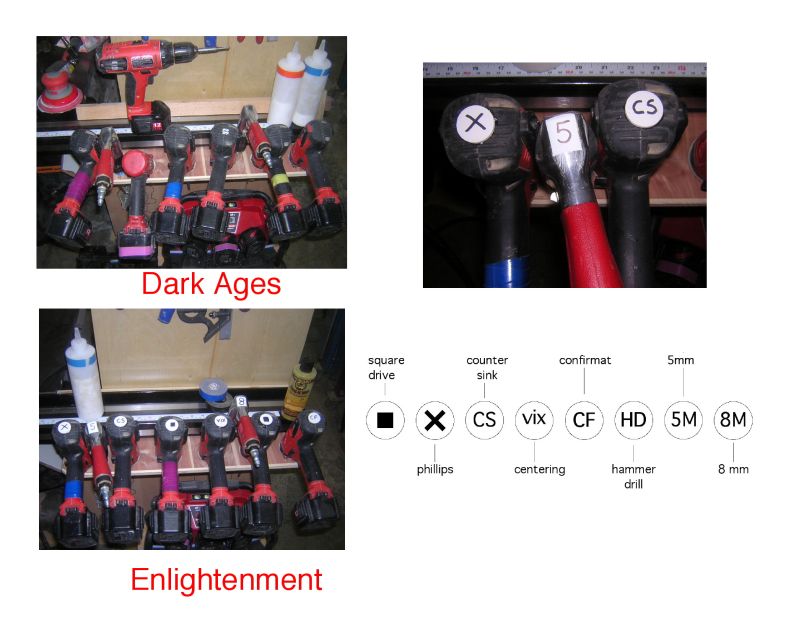

Useful thoughts on labeling and organizing multiple drill/drivers in the shop, plus an epiphany about turgid nomenclature. September 26, 2009

Question

About a week ago I made a post about how to manage battery drill tips. Specifically I was trying to come up with a quicker way to locate the drill tip I wanted, without having to do drill X drill research.

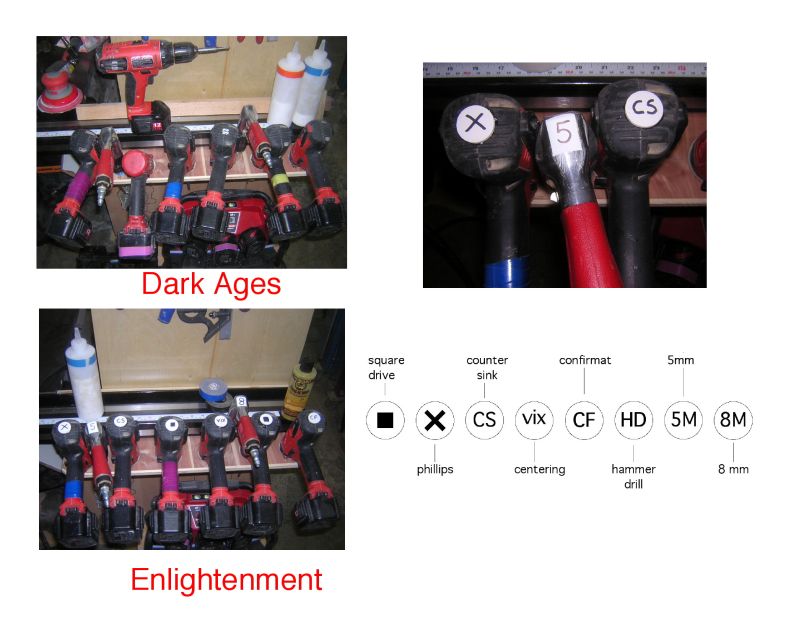

Many of you offered some great suggestions. Here's where we are so far. The white painted discs came from the hobby section of the local fabric store. They also had a great tube of glue that bonds well with rubber. Not including the blog last week or the actual shopping at the fabric store, we leaned out this problem in about 20 minutes. As some of you suggested, we will next develop a way to assign a specific location to a specific bit profile.

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor S:

I love your idea because it will make me buy more drill/drivers.

From contributor G:

We have entered an age where "leaned out" is a verb? Oh well!

From contributor O:

I have leaned out of a window, but as of yet I have not leaned out a problem.

From contributor E:

What size is the square drive?

From contributor A:

Which brand of gun are those red ones? They kinda look like Makita, but they are usually green.

From contributor K:

All you do is put labels on the gun rack that correspond to the drill. When the drill is in the rack, you can see which is which, and when the drill is not in the rack, you can see where it goes...

Click here for higher quality, full size image

From the original questioner:

That's a pretty good drill rack. I'm going to add something like that to what I have in place right now. I'm just real happy to have any viable way of not having to play "Where's Waldo" with my drill motors.

Contributor E, we only use #2 square drives, although if we change this anytime soon we will need to upgrade the icon.

Contributor A, those are Milwaukee drills. They're pretty tough. You can drop them on the ground and they won't break. We used to have a bunch of Makita "T" body type drills that cracked where the handle met the motor whenever they got knocked off the bench.

From the original questioner:

Contributor K, I was thinking about your drill rack some more. It is definitely a better system than the one I had last week but not as robust as the one I have right now. Your method requires compliance. It relies on good citizenship and depends on people agreeing to follow a system. My system (in combination with the drill tip being taped to the chuck) is self-sustaining. Yours plus mine is better than mine alone.

From contributor C:

What if all employees who use drills have their own quiver of, say, 10, so they can deal with their own issues of confusion... Does manic depression syndrome come to play in your shop?

From contributor K:

To the original questioner: If you re-read my post, that's exactly what I had in mind. When the drills are in, you can see the label on the drills, when they are not, you can see the labels on the rack where to put the drills... If the labels get ratty, just replace them as needed, but it you put clear box tape on the labels, it will protect them more...