Melamine Wall Cabinet Design

Other Versions

Spanish

Sturdy construction with an unfamiliar material. July 20, 2004

Question

We build face frame cabinets, which up to now have been all plywood sides, tops, and bottoms. We've been asked to do a job in melamine. They want 3/4 sides, tops, bottoms, shelves. Our plan was to use 1/2" backs rabbeted in about 5/8" to help reduce weight a bit, and we're wondering if we should use nailers or if any of you just screw through the 1/2". We've always used 1/4" with nailers on wood. If we use nailers, would you recommend we rabbet our tops and bottoms and join the 1/2" backs using glue and staples (our preferred method), or just flush them with tops and bottoms and glue and staple? We don't want to blow the backs out when we screw them to the walls.

Forum Responses

(Cabinetmaking Forum)

From contributor M:

I never use nailers with 1/2" backs. Our backs are 1/2" and planted on, tacked with staples and then screwed. The only time we dado our backs are for the finished ends.

From the original questioner:

Thanks for the quick reply. We're pretty much committed to rabbet the backs since the owner has made that a stipulation. What do you think about rabbeting the back - Roo glue and staples with hot melt for a little extra insurance? I'm just wondering if, when they're screwed to the wall, it won't pop the backs out.

From contributor K:

If you make your back flush with the sides, you should not have any problem. If you leave any reveal on the sides in relation to the back, I could see your concern.

From the original questioner:

Maybe I'll just rabbet 1/2" and that way they'll be flush. How does that sound?

From contributor J:

1" rabbet

1/4" back

3/4" nailing cleats (top and bottom)

(or 1 1/2" rabbet if you want a scribe)

makes for a nice tight box that will stay square

From the original questioner:

Actually, one of the guys suggested 1/4" backs, but not being melamine-literate we thought maybe it wouldn't be strong enough. Do you pockethole your cleats to the top/bottom and sides then, or what have you found that works best on yours?

From contributor A:

We do the same as contributor J. We use Roo for any melamine to p bd or wood attachment, pocket the nailers in. Confirmat the cases with Roo, dowel the exposed ends. Follow conventional fameless casework practice and all will work great. A good edge bander and either a scoring panel saw or nesting CNC are required to do a good job and make money, too.

From contributor J:

What contributor L said is pretty much standard around here, except we don't use dowels, just conformat and glue. We've never had a callback due to racking or looseness.

From contributor R:

Been using confirmat exclusively for 13 years. Never had one failure! Never mind the glue - it just makes a mess.

From the original questioner:

Thanks for the excellent and timely replies. We are leaning toward 1/4" backs and will place our nailers in back. Incidentally, these are all 1 1/2" ff cabinets. This is a deviation from our standard cabinet design. Normally, our nailers are on the inside of the box in front of the back, rather than behind the back. What is the best way to handle the top and deck? We don't have a CNC - just use dado blades. I'm thinking about running a 1/4" groove in the sides 1" in from the back edge and sliding it down from the top of the box and into a dado on the bottom deck. How do you folks do yours?

From contributor K:

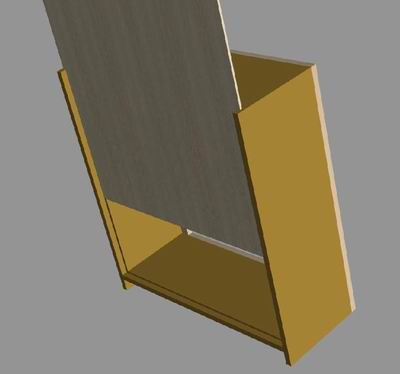

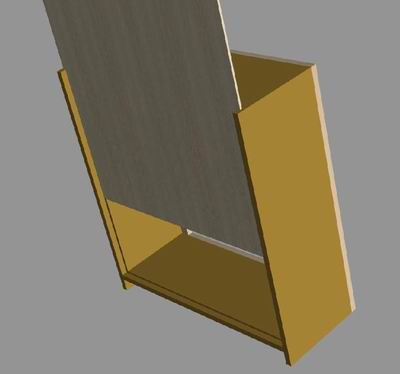

I run a groove in the sides inset 1" as you stated, but I cut the deck and top 1" short so the back slides past. The back is stapled to the deck and top and then the nailers are pocketed into the back.

From the original questioner:

That makes it simple enough. You just cut your backs the same length as your sides then, and your nailer extends down to the end of your back, correct? I'm curious as to what some of you use as nailers, since they're not exposed like ours are.

From contributor K:

I normally use 3/4 poplar for my nailers, but this is also a good place to use up scrap plywood. For melamine finished interiors I also inset the top the same as the deck and this allows me to screw the cabinet to the wall without having any exposed screws on the inside of the cabinet box.

From the original questioner:

That's pretty much what we planned on doing as far as the nailers go. "No screws on the inside of the cabinet box." That makes sense, but in our case it looks as though there will be a soffit, so we'll have screws on the inside. I just noticed in your drawing that you have a third nailer in the middle. May I ask what purpose it serves?

From contributor K:

For melamine I probably wouldn't use the third nailer (unless it were for a very tall cabinet), but with plywood I seem to get so much bow that I sometimes use them to pull the bow out of the back of the cabinet.

I show them in all my basic cabinets in the design software. That way, if I use it, my cost is covered; if I don't, I am that much ahead.

From the original questioner:

It's really interesting to see how other folks do things. Do you also build your base the same way with the groove in 1" and the nailer behind the back? Do you build wood, melamine, or both? If melamine, what kind of screws do you use?

Once again, thanks for the information. We seldom get to talk with other shops, and when we do, they think they need to keep their information proprietary.

From contributor J:

What if this is a mel interior and it's white? Then the white will show when your back is as long as the sides. Then the white will show on the exterior bottom?

From the original questioner:

It appears from contributor K's drawing that it will. I have seen some that extend the deck all the way back to eliminate that, but I've seen a majority the same way contributor K does his. Do you have a preference?

From contributor K:

No, for base cabinets I just staple the back on, and the nailer is inside (hidden by a drawer). If I have an exposed end I rabbet the back in there (usually not a problem because most of my ends are raised panel). I don't build much with melamine (not set up for it) but I have been getting calls for finished interiors, so I am using more. The only time I inset the back on a base is if it were to be an open cabinet.

The mel showing below the uppers isn't an issue with me because I use a molding and 1/4" ply to finish all my cabinet bottoms. You could always just cut the back to the bottom of the deck and raise the nailer to eliminate that problem.

From the original questioner:

What design software are you using?

I have another question regarding melamine. On our wood uppers, we groove the stiles to accept the sides, then dado the sides for the tops and bottoms and just glue the top and bottoms to the rails with no fasteners. Will Roo glue or Titebond melamine glue be sufficient to hold the ff tight against the rails? We thought about pocketing, then covering the bottom of the deck, but question whether it's really necessary. Any better suggestions will be appreciated.

From contributor K:

I generally pocket screw my face frames to the box, but as I said I usually cover exposed ends and the underneath side of uppers with wood.

I use eCabinet Systems for all my designs.

From contributor O:

Contributor K, very nice looking cabs and I like your construction methods. I think I'll try that on the next job.

I also use E-cabinets. Getting pretty good, isn't it? But I have to ask you how you got the pocket holes to show on your cabs. Haven't seen that option yet. I have the new beta version that I hope will be distributed soon.

From contributor X:

I build a frameless box using all 5/8" or 3/4" thick melamine particleboard. Some specs are for 3/4" but most of my frameless cabinets are 5/8".

I use a full thickness back (5/8") with 2" particleboard screws in pilot hole. The full thickness back squares the cabinet and screws can be driven anywhere to mount the cabinet.

If it's a white cabinet, I use white double side melamine. If it's a veneer cabinet with wood doors, I use sheet material that's faced with melamine on one side and wood veneer on the other and use the appropriate edge tape.

If the sides are exposed and not covered with an end panel, I use biscuit joinery and edge tape on the overlay back edge. The bottom edges of the sides and back board are taped for any style cabinet.

From the original questioner:

Does anybody have good ideas as to how to handle the back when using a 1/4" back? I like the idea of using the 1/4" material, just not certain of the best way to handle the back being exposed at the bottom. These will be all white melamine interiors, by the way.

From contributor K:

The only other thing I can think of is what you talked about earlier. Slide the back into a groove in the deck. Band the bottom edge of the sides.

From the original questioner:

Contributor X makes a good point with planting the back on. We don't have 5/8" material ordered, but I could use 3/4 and plant it on. I was just hoping to reduce the weight a little with 1/4". I could use the 1/4" for the backs on the base cabs since we already have access to that.