Metric Versus Imperial

Point oh six of one, half a dozen percent of the other ... February 13, 2013

Question

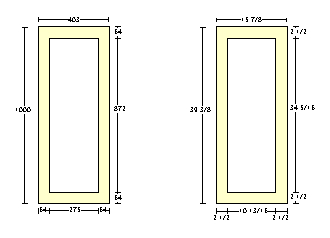

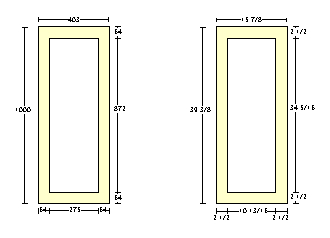

I have a customer who wants to build their own leaded glass windows. I would like to know visible glazing dimensions. We build in metric and have to communicate in imperial.

Imperial math involves:

1/2

13/16

7/8

5/16

3/8

Metric involves simple integers.

Could this be one of the reasons America is losing its manufacturing prowess? We simply don't want our workers to have to stretch their brain to learn an easier system of math?

Forum Responses

(Business and Management Forum)

From contributor J:

Playing around with common denominators can stretch some synapses. On the other hand, measuring half of 15/32 is easy, double the denominator, try that with 7mm. They are both measuring systems mounted on number systems and both can run into seemingly irrational results, like breaking a five inch (or centimeter) span into three equal parts. At some degree of precision, you just fudge it. It would be nice to be metric, although my grandfather's tools would be obsolete. It is kind of silly that your client can't or won't translate though - the physical space doesn't change, just the units of measure.

From contributor L:

I sure wish we'd officially go metric. 7/2 = 3.5!

From contributor G:

Translating English and metric measurements is easy simple math. C to F or vice versa - not as easy.

From contributor C:

I communicate to my customers in Imperial measurements. I build cabinetry in metric in the shop. How do you handle the 32mm spacing between holes with most cabinet hardware - "one inch and a quarter and a smidgeon"? If your employees can understand that 100 pennies make up a dollar, they can learn the metric system. Even easier than that, keep everything in the same unit of measure: millimeters. Don't bother with centimeters, decimeters, etc.

From contributor M:

To a very large degree, we all live up to the expectations other people have of us. Back in 2000 I went through the very fine True 32 training program Bob Buckley offers. Up to that point we were using the imperial system. When I came back, we went to metric overnight. Of course I offered no options of which measuring system to use and I don't remember having any issues. Since then new employees have adapted. I do not believe all my employees are smarter than average. It boils down to expectations from the people you have some influence over, whether it is you wife, kids, employees, whomever. Clients on the other hand, well, Imperial is fine when dealing with them.

From contributor R:

Don't give them any numbers, give them a template. Everyone gets grouchy when the glass doesn't fit.

From contributor B:

We work in metric, converting to imperial for clients who "speak inch" is pretty simple. My biggest headache - our installers would phone in measurements for new parts in inches. Needless to say mistakes in conversions led to parts being made incorrectly. It was rare, but rarely adds up over time. To finally put a stop to it one of our installers said he needed a part 6 x 96. So a piece 6mm wide by 96mm long was made and sent to him and I haven't had a problem since.

From contributor E:

I work in digital inches now. Most digital measurement devices will do .001" but only .1mm, so I can be more accurate. Although I rarely go beyond .005".

From contributor I:

Once I got my CNC router I started thinking like a machinist, and now I work in decimals. (.125, .005, and .250 etc.). I never have to do anything beyond basic, elementary level math. I keep a metric rule around and I never use it. They tried to teach me in school that the metric system was superior, but I just don't see it. Thatís not to say I don't use it from time to time when it has its advantages, and I do own metric rules and calipers. Sometimes itís nice having two totally different systems.

From contributor E:

With the appropriate measuring devices it would make little difference to me with measuring. If you gave me a metric tape and told me metric measurements I wouldn't have any issues building anything, it's just numbers. I do have a problem visualizing 452mm without converting to inches in my head. If I have a bunch of imperial measurements that need to be converted into metric I would just grab my calculator and go for it.

I had to do a kitchen for a woman who came over from Italy. She really didn't understand imperial the same way I don't understand visualizing metric. Whenever I was talking with her I would have to convert inches to mm. So that is what I did - not a problem.

From contributor K:

2.54 cm = 1 inch. That's where my mental conversion capacity ends. I'm a calculator guy after that. I taught science for ten years and still refuse to "think" in metrics. If you need a dimension in metrics, sure let me grab my calculator. I'm sure it would be the exact opposite had I not grown up in the US.

From contributor A:

I moved to South Australia a couple of years ago from Connecticut. I've worked here as a carpenter (lots of steel, fiber cement, and masonry) not much timber. I had only used a metric tape in the US shop occasionally for hardware installs. So I would have called myself a metric newbie. I can now switch back and forth quickly. I do prefer the metric for carpentry and woodworking. It causes much less confusion when dealing with other workers. However, I still have trouble visualizing mm. We only talk mills and meters, no centimeters.

The interesting thing is because of our world economy and past history, AU is not totally metric. If you walk into a hardware store 1/3 is true metric, 1/3 is fake metric, and 1/3 is inch (imperial or SAE). Plumbing is 50/50. The fake metric is very common (50mm is rampant on labels even though it measures 2 inches). I always love hearing about the 15 meter mast on the 20 foot sailboat.

From contributor B:

I think for me it simply boils down to what you are most comfortable with. I don't think either system is inherently more accurate, or conversions really aren't that difficult. I have a calculator with a from-to metric function. If a contractor or client wants measurements in inches again no problem, I just need to turn on the alternate dimensions in AutoCAD. It's mixing the two systems for production that I have the issue with. I'd say that a conservative estimate would be around 80% of manufacturing defects around here is a result of poor communication, so consistency in terminology and standards are huge.

From contributor K:

To me imperials are better and easier, and I was born and raised on metric. The thing is that computers can't understand imperial and fractions, all input needs to be in metric and decimals. Also people are accustomed to visualize in inches and when you tell them 914.4mm they have no clue how big is that, but they all know 36".

From contributor O:

The shop should use the system they grew up using. The Imperial system may be a bit more difficult for those mentally challenged, but using it also challenges the person to think. I don't agree that we should make thinks simple. People become lazy learners when everything is presented to them in a simple form. The problem with conversion is it is only good to 3 decimal places accuracy. In CNC and precision machining, you need to go 4 and even 5 decimal places in some instances. There are good arguments for and against either system, but boils down to whatever is the most comfortable to use.

From contributor S:

I call myself 'bi-measural' - sort of like bilingual. I used to be a school teacher and metric makes it harder for kids. When you have a lot of different units, you understand the concept of length, as being different from the concept of the unit of length. When I taught physics I would deliberately mix units up in problems to get the concepts behind the units clear. Yes, I actually did write a problem where I used furlongs per fortnight. I'd also do things like give a pop quiz, and tell them that they had two micro-centuries to do the quiz. Problem one was "convert one micro-century to seconds."

Addition and subtraction of imperial fractions is a pain, and is error prone. It's not the Imperial part that is the problem. It's the fraction part. Machine shops work in decimal inches all the time. Usually three places accuracy for rough items, four for precision work.

Lots of people don't visualize centimeters well. A compromise for dealing with this customer would be to work in decimal inches. Sheet goods in Canada are sold in 4 foot x 8 foot by X mm. So I can buy 18 mm plywood or OSB. Or I can by 23/32 OSB or ply. I now take a dial caliper with me. The last batch of OSB I bought was 0.704" Which is just a hair over 45/64".

It's usually the thickness of anything that will screw me up. You build, thinking your 3/4" stock is 3/4 inch and itís six thousand short of that. Or it was 3/4 before the melamine went on and it's six thousand over that. The line of cupboards is ten panels thick, and now youíre out by 60 thousand - almost 1/16" which is why you build in overhangs. Don't cut the counter-top until after the cabinets are made. Or split the difference and get clever with colored grout or caulk. Or you figure this ahead of time, make the units a smidge under, and put in one layer of duct tape as needed to make things flush.

From contributor A:

I grew up metric and then moved to the US and worked in a machine shop using decimal inches because fractions are impossible on small dimensions. Then most people needed a chart to convert from decimal to fractions and another chart for GA when working with sheet metal and another chart back to metric. I never saw a chart in Europe - there are 1000mm in a meter, 1.000.000 mm in a kilometer. How many inches are there in a mile? Oh, I lost my chart. How many cubic inches are there in a gallon, ah that was another chart. I agree with folks that getting a feel for how long an inch is vs. a centimeter or the other way around takes some time. I now speak both and ask my customer what they prefer, the shop uses metric. To the guy with the glass; print a chart and give it to the guy making the glass.

From contributor T:

I was a die-hard imperial guy before the market was inundated with metric products, i.e. hinges, drawer guides, cabinet pulls, etc. However, once I set my mind to it the switch was easy. My only problem is the mindset that everything has to be related to imperial. Instead of making my toe-kick setbacks at 76.2mm (3") I make them 75mm, instead of worrying about making them 4" high, they become 100mm Ė simple.

As far as my customers are concerned, my cad program will allow me to convert presentation drawings back and forth or display both dimensions together. My shop drawings are always in metric, cut sheets are in metric, my European made CNC loves metric, my workers have adapted without too much grumbling and my desk top calculator is usable again. We can look at a distance and easily estimate the length in inches and/or feet, but coming close in mm is something that needs practice. Good luck fighting the inevitable if you so choose, but the sooner you see the writing on the wall, the sooner you'll learn the system and once you learn the system, you'll never look back.

From contributor H:

We only use Imperial measure in the shop since all out tools are graduated in this form. Orders with metric dimensions are converted by computer or construction calculator before building starts. Digital calipers and other measuring devices sure help.

From contributor D:

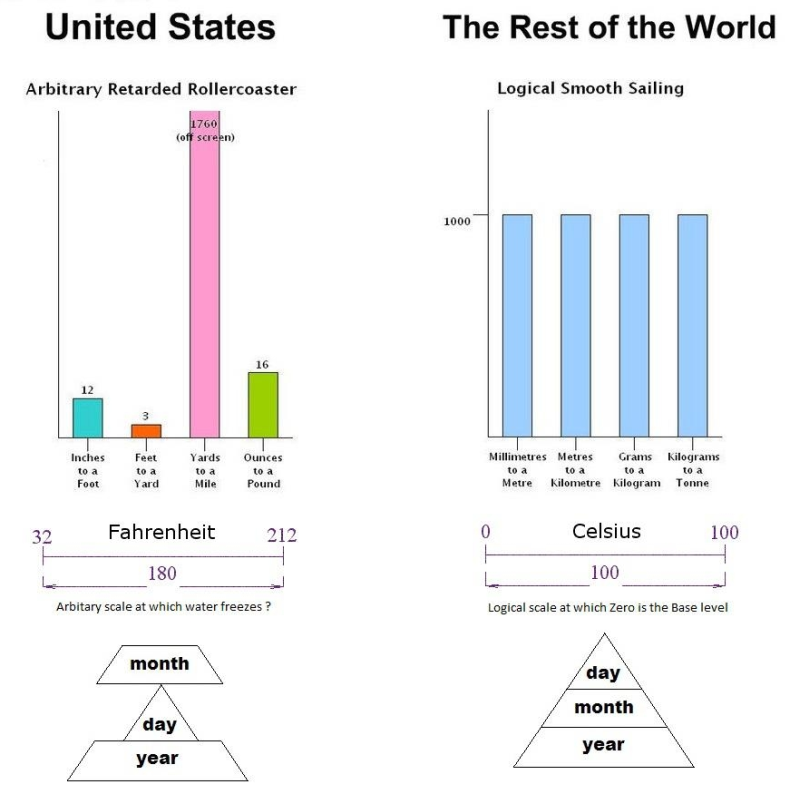

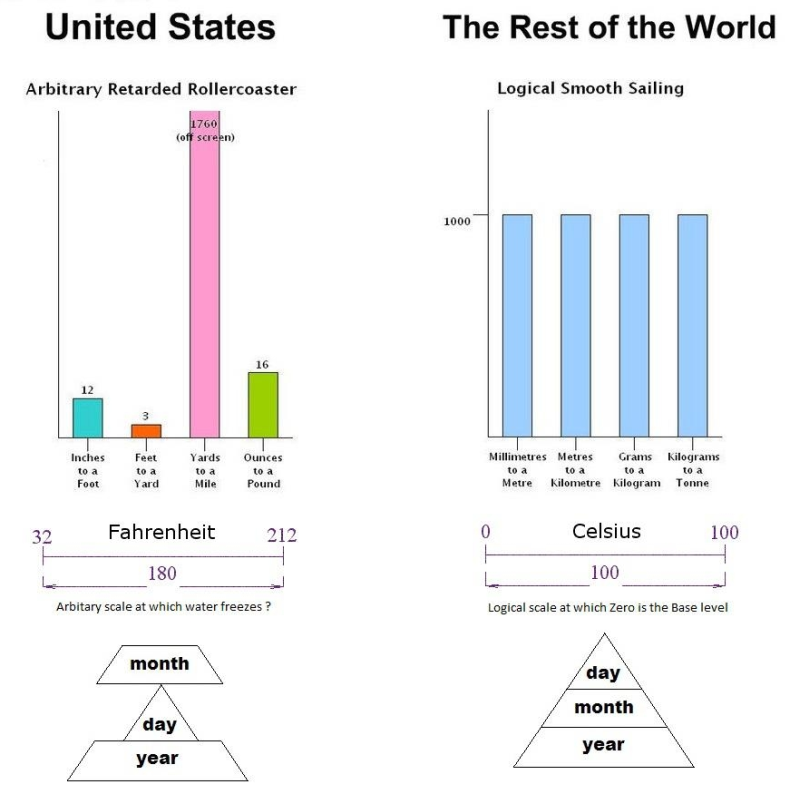

Hasn't this sunk in yet?

Click here for higher quality, full size image

From contributor N:

I always submit drawings in metric. If the architect or designer want to convert they can assume the risk themselves. I always measure in mm and input as mm. This was not easy for me to get used to because I was raised with inch/fractions. Try this - all internal dimensions are metric, incoming inch measurements are converted to the nearest .01mm, and that is the end of it.

By the way, it is not just the USA. I am in SE Asia and it is worse here. Machine shops use inch/decimals (1.3425"), carpenters use foot/inch/fractions, modern cabinet makers here use mm, most architects use meters, and designers use feet or cm (sometimes on the same drawings). All my machines use mm, but my workers think in inches! Download a good unit converter for your smart phone.