Question

We have recently improved our shop with a space saving idea. For a bunch of wonderful reasons, our chop saw needs to be moveable from day to day. The problem we were having was that there was no great spot from which to feed the electrical cord. What was acceptable in some circumstances was a hindrance in others.

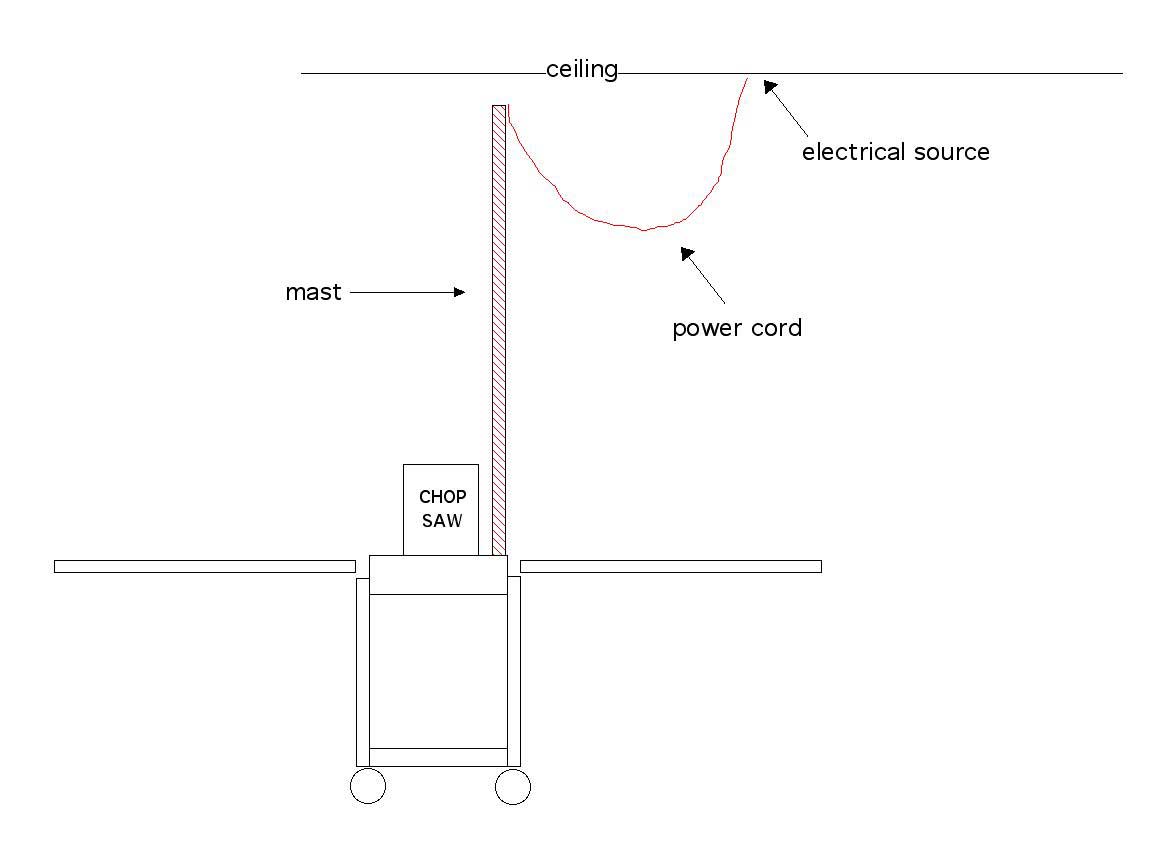

We would find ourselves having to compete with this cord when moving people or carts through this district. The solution, as you see, was very simple. We affixed a mast to the chop saw and now feed the electricity from the ceiling. A simple loop hangs down and allows about a 20 foot radius when quickly moving the chop saw in and out and around the zone. It's amazing to see the amount of free floor space when you don't have to dodge a cord.

What I would like is some help with the castors. I have some fairly expensive castors on another cart that theoretically lock when a lever is engaged. The problem is that sometimes fine sawdust gets between the lock and the wheel and the cart still moves.

I would like to find something similar to a library stool. I would like the castor to engage when necessary and completely disappear when necessary. I remember seeing some a hydraulic tool here recently, but I hope to find something a little simpler. Does anyone have any ideas?

Below is a drawing of the setup we have right now.

Forum Responses

(Cabinetmaking Forum)

From contributor F:

Is your cart so heavy that you could not put a couple of 2x 4s under the cart so the casters just clear the floor? I wouldn’t cost anything.

http://www.rossdesign.net/Hydrauliccasters.asp

We also have our chop saws (and planers, jointers, table routers, etc.) on rolling carts and had the same problem with movement. We attached small push-type toggle clamps vertically to the fronts and/or sides of the carts along the bottom edge (aimed at the floor) so that when they are engaged they push the cart up off the floor 1/4" or so. It holds all our carts steady, not perfectly, but close enough.

I know I haven't explained this well enough, so here's a link with both large and small push-type toggle clamps from Rockler. Once you see the picture, you'll get what I mean.

http://www.rockler.com/ecom7/product_details.cfm?offerings_id=2150