Paint for Solar Kiln Interiors

Details for painting the inside of a solar drying kiln, and some resources for kiln design. June 9, 2007

Question

I am in the final stage of assembling my solar kiln. I am using double walled polycarbonate glazing. Does it matter what type of black paint is used on the inside collector surface? Considering the great fluctuations in temperature and humidity, has anyone found one more durable than another?

Forum Responses

(Sawing and Drying Forum)

From Professor Gene Wengert, forum technical advisor:

The inside of the double-walled carby is not painted. Rather the sunlight is allowed to hit interior kiln surfaces, painted flat black, where it is absorbed and converted to heat.

From the original questioner:

I meant to describe the inside surface of the kiln where light will be striking, not the polycarb panels. I know black paint is used. Any recommendations regarding type for longevity?

From Professor Gene Wengert, forum technical advisor:

Flat black, and you usually get what you pay for.

From contributor R:

I am just getting started on the process of learning about solar kiln drying. I contacted Dr. Brian Bond at Va Tech which is about 25 minutes from me. He sent me plans for a solar kiln they designed. I will quote him on the black coating and hope this will help you.

"The plywood inside the kiln was painted with two coats of black rubber-based cement sealer, which, when dry, acts as a vapor barrier and black solar collector. Another option would be to paint two coats of aluminum paint for vapor barrier and then a third coat of black paint to absorb the solar energy."

From Professor Gene Wengert, forum technical advisor:

The present VA Tech kiln mentioned above is a design copy (same design but twice as large) of the original VA Tech kiln that I designed in 1978 and has been widely published and given various names (including WI, OR, IA). The key design element is 1 sq ft of roof per 10 bf of kiln capacity.

In this latest version, there are some excellent suggestions for really making it a superb solar unit. The original design and kiln (which lasted at least 15 years at Tech) had both a 1000 BF and 1500 BF size and was perhaps too concerned with keeping the cost at a minimum. Nevertheless, the original design still works and is still available and is still being used. (The lack of having a perfectly tight structure meant that we did not have to vent as much!) Certainly some building materials improvements have occurred in 30 years, so it is good to see how Dr. Bond has changed a few construction techniques and tools.

From the original questioner:

Thanks - those where the details I was looking for. There is a lot in the archives about construction and design, but little about specific paints/sealers.

From contributor B:

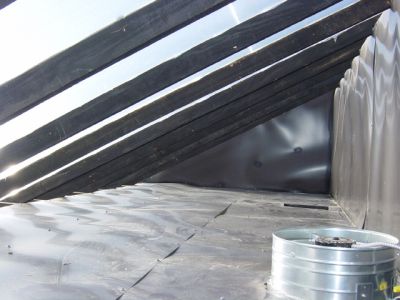

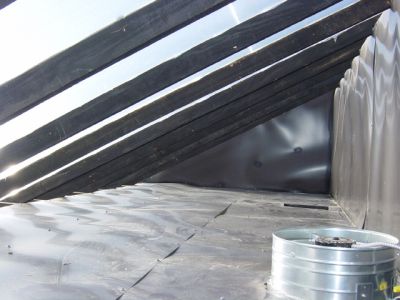

Mine is not the greenhouse version. I have an attic collector that I blow the heat through the stack from with 2 attic fans. I do not know how this would work on a greenhouse version, but I used 20ga 4'x10' flat sheet metal with baked-on flatblack enamel paint on one side. The side placed down against the insulation is white enamel. I installed it right to the 2x4 studs and ceiling joists and traded the cost of plywood and paint and upkeep for the tin cost. I am not sure how it would stand up to the additional moisture in a greenhouse version. Mine works well and maintains a working temp of 180 to 200 deg with the fans running in summer months. Once while unloading/loading on an August morning, I turned the fans off until about 11AM and the collector temp was 320. (Thought about going to get a Brisquit.) Kiln temps range from 140 to 160 during this time with dryer wood. Another plus that I sometimes do is, if I get a board that has bugs (PP beetles), I put it up there for about a day and cook 'em real good.

From contributor L:

I built Dr. Gene's version 12 years ago. The outside has been painted twice and needs it again. The inside was painted with flat black latex and still looks like new... if you overlook all the dings from loading and unloading.

From contributor J:

I used the aluminum paint top-coated with two coats of the best exterior flat black on the inside. Mine is also in good shape, except for the occasional dings, although the outside needs painting now. When I built this kiln, I lived in an area with shade. I only received good sunlight from 10-4. Now I live where the kiln gets a clear view of the sun all day and the paint is still holding up very well inside.