Reprinted with permission from SprayGunWorld.com.

Note: When setting up a spray gun for spraying a specific material, it is recommended to use the lowest possible pressure settings to achieve the desired results. Excessive fluid and air pressures result in premature nozzle replacement, greater overspray, and more frequent booth filter replacement.

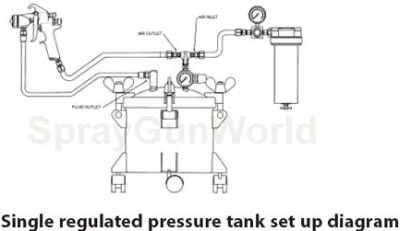

This is the most common setup for HVLP units. We recommend you have a fluid control regulator, gauge, or mini diaphragm regulator on the bottom of the gun, but it is not necessary.

Click here for higher quality, full size image

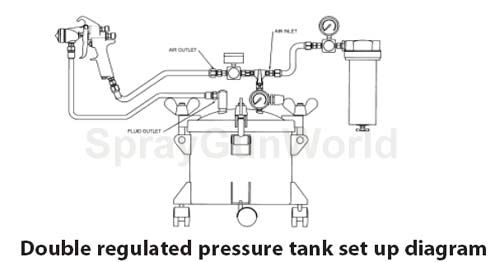

This setup adds another gauge on the line to the spray gun. If you do not have a fluid control regulator, gauge, or mini diaphragm regulator on the bottom of the gun, this 2nd gauge will help you regulate the air to the spray gun. This is especially important for HVLP units.

Click here for higher quality, full size image

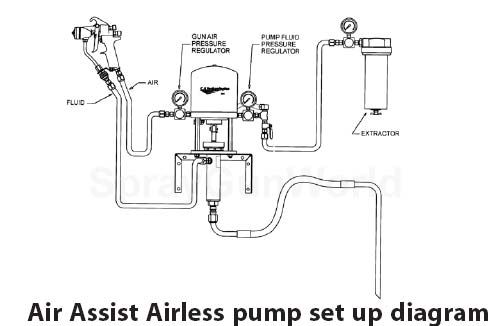

Air Assisted Airless Systems are for production houses. They are faster moving units and use an additional pump system in addition to a compressor.

Reprinted with permission from SprayGunWorld.com.