Question

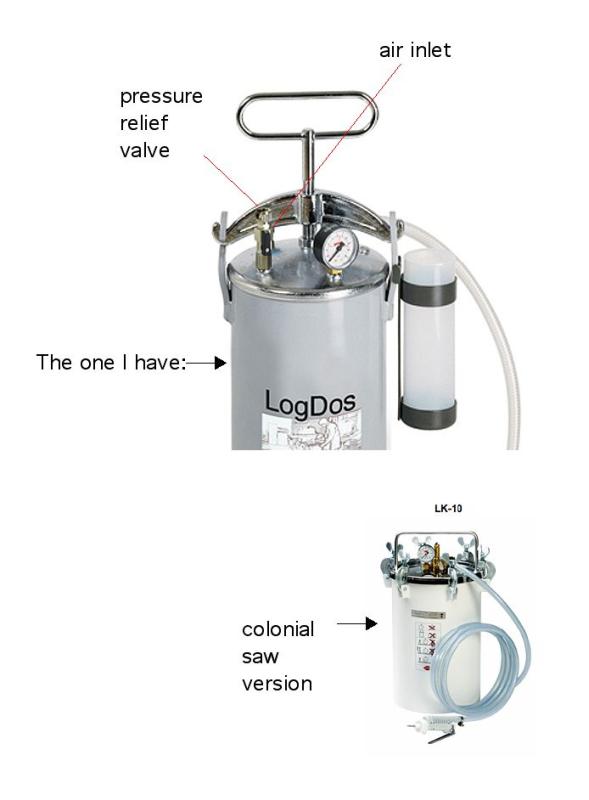

I have some more questions about pressurized glue pots. I have an opportunity to buy a used glue pot from a fellow who closed his shop down. He bought it from the people who sold him his HESS clamp. I have it at my shop right now but have not yet put any glue in it. I did charge it with air and this is what we have observed:

There is a warning label saying not to exceed 5 BAR. The pressure gauge reads both pounds of pressure and BAR. I am not sure what a BAR but the equivalency seemed to be about 60 lbs so that is what we ran it to.

There is an on-off switch inline with the air feed fitting but no otherwise apparent way of knowing when to stop feeding air. Initially we thought it might be missing a regulator but the HESS website does not show one. The pot from Colonial saw also does not seem to include a regulator.

My question is: how do you load the air, or rather, can you load too much air? There is a pressure relief valve. Do you juice it until this kicks off?

Also: after we put 60lbs of air into the system it seems to slowly leak pressure out. It is a slow leak but a leak nonetheless. I don't have any experience to compare this with. Should it be leaking air slowly? As I understand from the HESS website, you are supposed to be able to charge it with air then unplug it for walking around. Is this how everybody else's works?

The fellow who is selling it never actually ran it so he has no answers. If anybody who is using a similar pot could tell me how theirs works I would sure appreciate it. Mostly I want to learn how to know when I have enough air and how long a charge of air should last before needing to be re-charged.

Forum Responses

(Cabinetmaking Forum)

From contributor O:

I have the Hess system with LogDos pot and Pizzi fittings. My pot is a little different, the relief valve and air inlet are separate. From your picture it looks like you have a black shutoff on the air inlet. We just put a quick connect on this. Connect the air line to it, open the valve till the gauge hits 5 BAR and shut it off. You donít need any more gauges. No stress about the pressure, they will pump glue even at 2 bar. We usually never recharge ours till the glue pot is refilled.

If air is leaking out check the gasket and rim of the pot to make sure everything is clean. You have to tighten these a little more than you would think. Our pot is larger similar to the Colonial pot in your picture. We have to tighten the wing screws in sequence a few times. Yours is a single pressure point. Check the gasket.

"What happens if you zone out and go past 5 bar? Presumably the pressure relief valve kicks off? Would this relief valve just reset itself when pressure drops to acceptable levels?" Weíve over filled ours, just bleed it off. The relief valve never went but if it does no big deal.

Also, (sorry for being obtuse), you said that you pressurize the tank and then don't have re-pressurize until the glue in the plastic pot is empty? Yes, if itís leaking time to check the lid and gasket.

"How feasible do you think it would it be to take some UHMW plastic and make a cope pattern for gluing ogee doors?" I think that is feasible but the small Pizzi brush might work as well.

Building cabinets you wonít go through much glue. I would be surprised if you fill the tank more than once every week or two in a small shop. If your careful to keep the inside lid and gasket clean at glue changes you should not have any pressure leak problems. We have a glue tipper on the cart that works good for filling the tank. I try to totally clean the pot and flush the hoses every couple years. You should have a threaded attachment to use a hose to clean the glue nozzles and attachments. The roller is the only one we have that requires care after use. The nozzle and dowel gluer are fine sitting in the water tank for days or weeks. Titebond 1 and 2 work easy in this. Titebond 3 gets lumps that sometimes clog the screen filter in the pot.

For house door assembly we use the dowel nozzle and a hand glue brush. I still like to brush a little glue on end grain. We just started using mortise joints on window frames. Pizzi makes an attachment for this but think I will try the brush first. For cabinet doors I think the small brush might be the ticket. You will be surprised how well the standard nozzle works for most things.