Preventing Long-Span Book Shelves from Sagging

More discussion on a perennial problem: stiffening long shelves. December 27, 2008

Question

I will be building some bookcases with shelves as long as 46". They will be about 10" deep. These will be part of a painted installation. What material have you used for shelves that wide, without sagging? These will be adjustable with no center support.

Forum Responses

(Cabinetmaking Forum)

From contributor K:

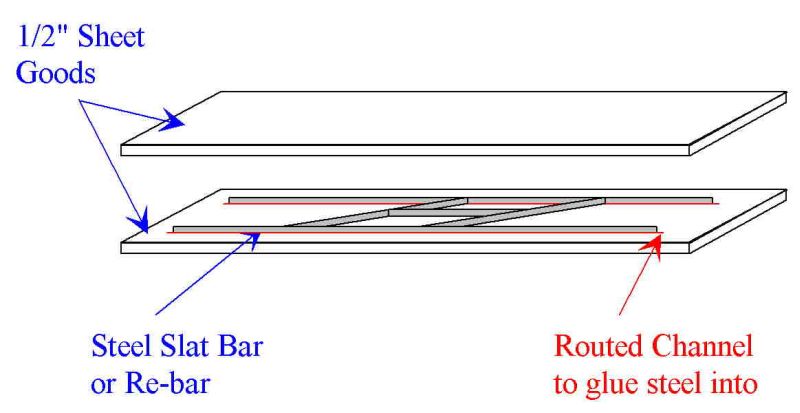

The short answer is a torsion box with hardwood on front and back (decorative hardwood edge on front, and veneer to cover back hardwood edge so no hair-line cracks over time). I haven't tried this myself (see below), but I will on the next long-span shelf. It's a takeoff of the torsion box, but I think would be quicker to fabricate, and probably stronger due to opposing forces of the ply and flat bar. What do you guys think?

Click here for higher quality, full size image

From contributor J:

Use 7 or 9 ply plywood with a 1" to 1 1/2" x 3/4" thick hardwood edge band. We used to make a line of computer furniture that had a 16" deep shelf 44" wide. I used a 1 1/2" x 3/4" oak front edge on it. I still have one of these cabinets. The shelf has a large printer on it, an old monitor, and a Vertical CPU with very little sag.

If you use import plywood, most of it has a crown in it, as it's basiclly junk. But the crown will support a lot of books before it goes flat. Most of that stuff has some unknown number of poplar plys in it. Could be 13 ply or more - they seem difficult to count.

From contributor D:

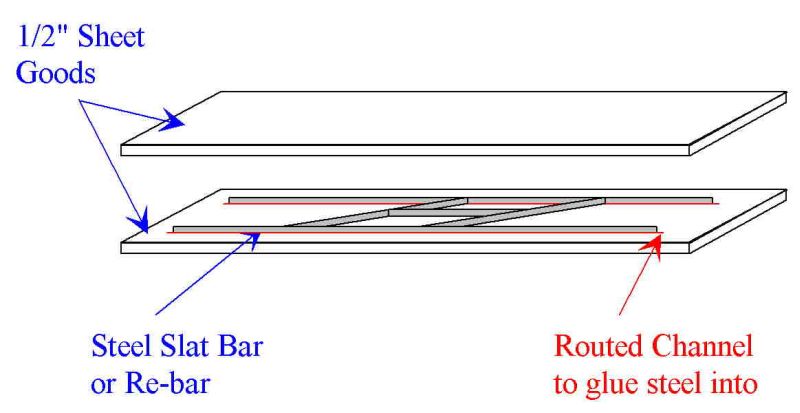

For wide painted shelves, I use MDF and pretensioned 1 x 1/8" steel reinforcement.

Click here for higher quality, full size image

From the original questioner:

I would like to avoid a 1 1/2 wide front and back band if I can. Is there any hope for 1" plywood? Torsion box? Thanks, but no thanks! MDF is the weakest material for a shelf and I sure don't want to put metal inside any shelf if I can help it. Okay, I only need a dozen or so of them, but that still sounds like a lot of fooling around to me. Has anyone tried 5/4 solid poplar? Perhaps a harder wood.

From contributor J:

I built a bookcase for my wife that was around 42" wide. Using some A1 beech plywood I added 1" x 3/4" solid beech to the front. After loading it up with books, there is no sag. Sometimes the easy solution is the one in plain sight. You could make all the shelves in less time than it takes think it to death.

Also you could add the same part on the backside. A lot of plywood has a nice crown in it these days. It's not a lot of fun building cabinets with it, but it's great for wide shelves. Plus you can pre-crown some hardwood for the front edge. Even 3/4" x 3/4" pre-crowned on both sides would work and it would look like you ran the shelves with tape with a edge bander.

NASA could engineer a great solution for about 12 million dollars.

From contributor U:

Check out the Sagulator in the Software Connection. I have had good luck using it.

From contributor T:

I offered this one up a couple of years ago and got thoroughly pounded for it. The scars have healed so I thought I would offer it again, because it works.

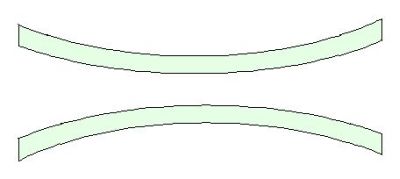

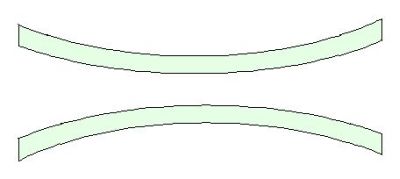

Take 2 pieces of 3/4 inch plywood and plane them down to 1/2 inch thickness. You will end up with imbalanced panels that are shaped like a banana. Glue them together as the drawing shows and you will end up with a panel that is dead straight and will not deflect under load. You cannot do this with just two pieces of 1/2 inch plywood. You must cause the imbalance in order to introduce the tension in the middle of the shelf.

From contributor M:

I built a unit that was 48 inches wide and used a 1 1/4 inch front on 3/4 oak plywood. It is now a couple of years old and has zero sag. They have some heavy material on the shelves and it does not affect it at all. Cutomers were happy. I have seen the shelving with metal support work okay, but I would not use it in a quality job.

From contributor C:

I don't think that 1" poplar will work at that span, and 1" plywood definitely won't, nor MDF. Not with a bookcase load, at any rate. If you don't feel like building a torsion box, then perhaps you should rethink your design.

From contributor L:

I was going to bring up contributor T's idea, but he did it first. Not *everybody* thought it was too weird!

From contributor P:

From a list in "Furniture and Cabinet Construction" by Andy Rae (good book):

Max spans for 10"W shelf @ 20lb per foot load

3/4 particleboard - 24"

3/4 MDF - 28"

3/4 Ply - 32"

Softwood

3/4" - 36"

1" - 48"

1 1/2" - 63"

Hardwood

3/4" - 42"

1" - 48"

1 1/2" - 66"

From contributor A:

It looks like a piece of 5/4 x 10" x 46" soft maple would do the trick. Mill it, paint, go get some lunch. Use the money you save on the torsion box to take a limo to the restaurant.

From contributor N:

I am in the process of building a set of bookcases with shelves from 12" to 46-1/2" wide and 15" deep. Not the first time for this. I use a 3/4" 9 ply for the shelves. Across the front I use whatever wood the cabinet calls for at this width and depth. I biscuit join the front edge with a 1-1/2 x 1-1/2 rabbeted with a 3/4" x 3/4" rabbet. Biscuits are alternated bottom and front across the width. I also glue and tack a 3/4" strip across the back and use a line bored center support on the back of the cabinet. Works beautifully. No sag. It is a couple of hours of work for the 28 shelves I have to build tomorrow, but I don't have to worry about load issues even under heavy use. My dad is a railroad timber bridge engineer. His philosophy... If a 2x4 will work, a 6x8 has to be better.

From contributor B:

"If a 2x4 will work, a 6x8 has to be better."

Yes! I've had great success (in a high end market) with employing this practice.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor G:

If you'd like the shelves to be light, super strong and use minimal materials make a sandwich. Use 1x2 as a banding around the perimeter, 1/4" plywood top and bottom and scrap ripped 1" wide, (width is unimportant but 1/4" is fine) notched and made into a 4" grid for the interior. Glue it up and it will be very strong. I made some 8' shelves this way that you can stand in the center and they weigh nothing.