Question

I am a small, one-man, part time shop that usually works with entertainment centers and shelving units. I have been approached to build cabinets for a bathroom remodel. Construction is not a problem. What I am wondering about is pricing the job correctly. The job is red oak with raised panels, coved drawer fronts and dovetail drawers (all outsourced - $1450 with hinges, shipping and packaging). Everything will be unfinished and installed. Any help with pricing and what you might charge for something like this would be appreciated. By the way, this is for the owner of my building where I lease my space.

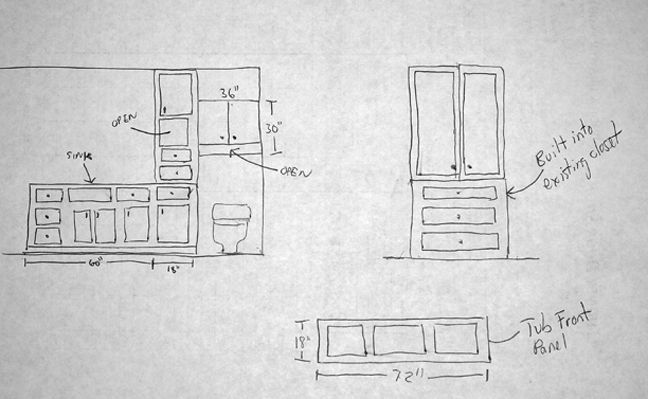

Click here to view full size image

Forum Responses

(Cabinetmaking Forum)

From contributor E:

How long will the job take you? You can use a material multiplier since the job is so small. If you're looking to give the guy a good price, I wouldn't go higher than materials x 3. Don't forget to mark up your materials by at least 10%.

I would look to see how much doors and drawers will run you. My guess is that he could not get that purchased and installed from a Big Box store for that much. If you are trying to do this guy a favor (he is cutting you a deal on rent, isn't he?), add up your materials, estimate your time to build and install. Next, figure the cost of overhead (how much a day does it cost you to keep the shop open (rent, phone, electric, gas, etc.) per hour. Multiply that by your time estimate - including install time because you are being charged this whether you are in the shop or not, and add that to your price. This is your cost. Want to make a profit? Multiply by 10-20%.

You need to know what your costs are. Otherwise, you will be paying him to make these cabinets. And personally, I would rather be sitting at home losing money than breaking my back, wearing out me and my equipment, subsidizing someone's remodel.

There are guys around here that are doing work for builders at $125/ft. Others are selling at $60/ft. I am not profitable at $125. The vanity et al would be around $1,562 at $125/ft. Then add per each d/t drawer and the price goes up. But again, this is all regional.

Figure your cost, take notes, and learn from your experiences. Some guys are just nailing their carcasses together, no glue or screws or backs ($60/ft). Others use plant-on backs, screws, but no glue. Others rabbet backs, dowel, glue, and screw. I would toss the ball back to you. If you think you can do it for that amount of time and he is willing to pay that for it, then go for it. If he balks at the price, start taking features (options) away, although it is harder to take away than to add on. He may not be interested in maple ply. It sounds like you have thought about it - now pull the trigger and see what happens. We all have different methods and can do this in different amounts of time. But if you are comfortable with your construction methods, your overhead, and the cost of materials, then shoot him the price. If you keep going at this pace and you don't get work, then you will need to evaluate your time, overhead, or materials.

An inexpensive cabinet program that makes cutlists will save you more time than you can believe. There are many out there, but we use Cabinet Solutions. If you don't want to pay $4000 for a design program, you can rent for about $100 per month. It is money well spent. Your price is good, but you should work to be as productive as possible so you can reduce that labor cost. It should not take so long to do this job if you are outsourcing the doors and drawers.

This is how my spreadsheet broke it down for me. Labor: 22.5 hours at $35 = $787.5. Door and drawer front cost based on supplier's costlist = $490. Materials for the boxes themselves are $278. Drawer box and hardware cost: $605. I charged $150 for delivery but I don't know how far away the job is. Even if the job is just down the street, it still takes time to load and unload both the cabinets and the tools to install, so I don't think that number is too far out of line. Install = $228. I took the total of all of these and marked it up 20% for profit and to add an overall fudge factor.

I love estimating with my spreadsheet. It helps me to not miss aspects of the job and make sure I am charging for all that I do. I also like that I have a budget for things like doors and drawers, so I know what my target is.

I have priced this project with face frame construction, red oak exteriors, pre-finished maple interiors, red oak open areas, raised panel doors, maple dovetailed drawers, ogee crown, Blum clip-top hinges, Blum tandem slides with blumotion, (you didn't spec this, but using dovetailed drawers without this hardware would be a crime, in my opinion), un-finished and installed.

Total price: $5335 plus delivery and install at an additional $480.

Looks like I'm the high bidder here, which is just where I want to be! This is my normal pricing and I'm always booked 2-4 months out all of the time.

Jim McDermott and Will Sampson (from the Cabinet Makers Association and Cabinetmaker magazine) have been giving a pricing seminar for several years now, stressing the importance of giving proposals that fairly reflect our talents and investments in our trade. We are professionals just like doctors, lawyers and car mechanics and should be fairly compensated as such!

Contributor R, I honestly don't see how you can make it with that pricing. Is everything cheaper in Texas? The cost of materials alone must be in the same range as they are here.

Even though the original questioner is a part-time cabinetmaker, if he inadvertently cuts the throats of the full-time pros in his area, then he is doing all pro cabinetmakers a disservice.

If there are those guys out there with a truck and a table saw who are willing to give this work away dirt cheap, they make it that much harder for the full-time pro who has a huge investment in his trade to win contracts that will compensate him fairly.

Again, I am not trying to be argumentative. Just trying to pass along some of the points that have been pounded into my head for years now. We all have to start somewhere. Many of us started out in our garage, charging ridiculously low prices, slowly honing our craft and slowly learning to charge more along the lines of a professional. I don't have a problem with these guys (that's exactly how I started out), as long as they are using this approach to become a pro. When they start competing with me to win contracts and they have no shop rent, no liability insurance, hardly any overhead - that's when it's a problem for me.

Right now, there is a guy who rented a shop right down the street from me, who started out 3-4 years ago. He does pretty low-end work for low prices. He has no contractor's license, no insurance and now has a couple of guys working for him under the table. I drove by his shop the other day and saw his guys spraying fancy carved corbels, which means he is starting to do jobs that are creeping into my end of the market, and it's beginning to piss me off! What's worse is the fact that he has a couple of unscrupulous builders that are using him on a regular basis, knowing how he is operating and taking advantage of his cheap pricing. I'm right on the verge of turning all of these weasels in.