Replicating a Textured Veneer

Sand blasting, wire brushing, CNC texturing? Woodworkers suggest ways to reproduce the look of an abraded Sapele veneer. October 13, 2012

Question

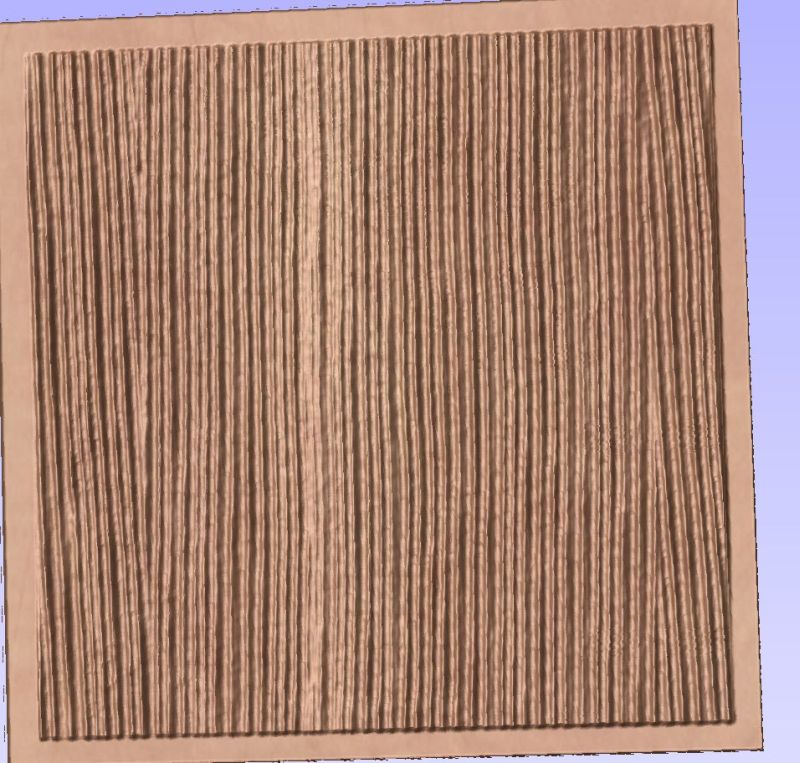

Below is a picture of a veneer that my client would like to have a bathroom door wrapped in. The veneer comes prefinished, so my concern is that at the seams in the door I'll have weak points for moisture to access the core (water resistant MDF). Also, access to the veneer is limited and costly, so there are no second chances. Can I replicate the grooving on a real piece of sapele?

Has anyone done this? I've tried wire cup brushing, but the sapele’s density us too uniform throughout. I was thinking of a v-grooving router bit run long grain by hand to create the intentional randomness that's in the veneer, but I don't know if I can achieve the groove density without it getting muddy. Does anyone have any ideas?

Forum Responses

(Cabinetmaking Forum)

From contributor F:

Wire brush machines are made for this. Performax and Quickwood both make machines.

From contributor R:

Try abrasive blasting. Vertical grain fir would look really nice like this. Sign makers used to do sandblasting in redwood, but most now sandblast using rigid urethane foam. They sandblast through parallel wires held in a frame to simulate vertical wood grain.

From contributor F:

You can sandblast with a variety of medium and get a similar look that may be acceptable. We do that along with some moisture to get the weathered look.

From the original questioner:

I'd love to use VG fir and sandblast it, but I don't know that I'd be able to accomplish the color and grain texture that my client wants from the sapele. Also being that the sapele is more of a tropical wood and doesn't have the climate variation to get the variety in density in the grain, would the sand/particle blasting still give that effect or would it just blow everything away? I like your ideas and I've considered some of them already. I'll have to get in touch with someone with a blasting cabinet and see what the impact would be on sapele. I've also seen that

Festool has a head for their power planer that would get me in the right direction, but I think that would be a little too contrived and machined.

From contributor W:

I did this directly from the photo in Aspire. Do you have a CNC?

Click here for higher quality, full size image

From the original questioner:

Very impressive! Amazing what technology can do these days! Unfortunately, I don't have a CNC, and I am not planning on that much of an expansion anytime soon. I do know a couple commercial shops in the area that have them. I honestly have very little knowledge of CNC technology. I know it's phenomenal on sheet stock, how does it work on solid stock? Would Aspire be able to continue the randomness of those lines over a 7' run? Certainly an intriguing thought. I've looked at a couple other options too. A friend suggested using a power plane with HSS blades and having the blades milled to a profile that I could overlap and randomize with my passes. I've found that Bosch and Makita both have HSS alternatives. Has anyone taken a similar approach?

From contributor W:

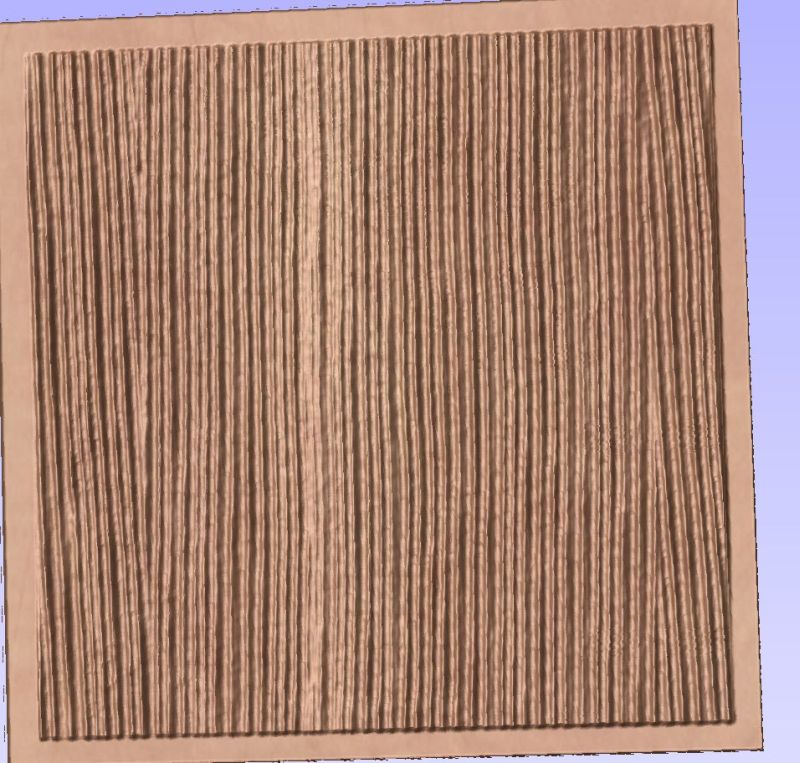

I am sort of in infancy with the texturing. I have done some decent work, yet I have a long way to go. I recently purchased a 20 foot CNC to just do panels. Check out the doors below, we did them from solid cherry.

Click here for higher quality, full size image

Click here for higher quality, full size image