Question

I want to set up a dedicated shaper for making shaker style glass cabinet doors. I have two machines available to me. Shaper 1 is a used 5HP 3-phase Powermatic with a 1 inch spindle. Shaper 2 is a brand new single phase 5HP with a 1 1/4 inch spindle. I favor the 1 1/4 inch arbor because this would allow me to possibly stack cutterheads on the spindle. I favor the 3 phase machine because I think it probably has more torque.

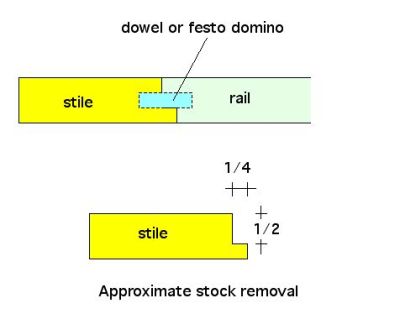

Can anyone look at the amount of stock I intend to remove with this machine and opine as to whether or not a single phase machine would be up to the task or if I should stay with 3 phase? I have power for both, so this is not an issue. I am not interested in using this shaper for other purposes other than the door. The material will likely be poplar, but could also be white oak or soft maple.

Forum Responses

(Cabinetmaking Forum)

From contributor B:

Either machine will work. I like a 1" spindle because I set my bits up in a stack with T-bushings all shimmed so there are no setup changes. I can make several cope and stick patterns as well as glass rebate by changing the bits, but no machine changes are required.

The 1 1/4" spindle is a heavier machine and might be a better choice. Without seeing the two machines, I wouldn't know. For cope and stick the 1" is all that is needed. A single phase motor produces more torque than a three phase motor during startup because of the extra windings the single phase motor has. The three phase motor is cheaper to make. No switching windings and no start windings. I went with three phase everything.

There are several advantages of 3-phase motors. First, as already mentioned, is cost, as they are typically much less expensive to make. Second - and the more important issue in industry - is current draw. Basically it comes down to the same amount of current being drawn through 3 legs on a 3-phase motor versus 2 legs on a single phase motor. This means you can use a smaller gauge wire to the motor. There is no electrical cost savings as the net result of drawing 5 hp worth of current is always the same. You can just use larger motors with smaller wires and breakers.

You state that you have both power options available. If you have 3-phase direct to your building, then the single phase motor will probably be running on 208 volts instead of 220 (or 230 or 240). That is done all the time but I believe there will be a slight increase in current draw to the motor.

If you are running a rotary converter on a single phase service, then you will have full power to the 3-phase motor as long as it is a properly built converter. If you are running 3-phase off single phase with a static converter then you will only have approximately 2/3 of the actual motor rating power.

Not knowing your actual building service situation, and so ignoring the power issues, I would go with the 1 1/4" spindle unit. If they are both equally well built machines, the one with the 1 1/4" spindle will be heavier duty since it has to support the larger spindle. And the larger spindle itself is significantly stronger. Also I think you'll find most shaper cutters either come as 3/4" or 1 1/4" bore, so why bother bushing it down if you don't have to?

I'm also not a fan of using bushings if not needed. I couldn't see buying a smaller machine knowing I'd be using bushings for everything... Just doesn't make a lot of sense to me.