Question

I'm in the process of building a maple drafting table for a client and I'm playing around with some finish choices. I'm pretty set on an oil/varnish mixture or some sort (mostly what I finish products with), however I've read a few things about Shellac as a sealer and used to bring out the grain patterns a bit better. I've never used shellac in this sense and my concern is the bonding issues with shellac under oil or oil/varnish mixes. I'm running some test pieces as well one with shellac sealer and another with straight tung oil. The shellac piece really pops the grain. Anybody have any experience in this finish? If so some insight would be nice.

Forum Responses

(Finishing Forum)

From contributor K:

I wouldn't. I think you are asking for trouble with the oil/shellac.

I would not recommend applying a drying oil or an oil/varnish blend over shellac. Drying oils like linseed and tung are a lot less durable than varnish and are not film forming finishes. By adding oil to varnish you only reduce its durability. When you want a "close to the wood" natural finish without a lot of protection from wear, heat, water, etc. then a drying oil or an oil/varnish blend is a good choice.

Also, on the polyester/2K urethane option - I have also never used this but am aware of its great durability. My only concern with this is that my table top is two feet of solid maple. With polyester's rigidity, I'm worried the wood movement will crack the stiff polyester.

Some varnishes are lighter in color than others because of the drying oil that's used to make them (e.g., soya oil). If you want the 'look' of tung or linseed oil, use a varnish like Waterlox or Behlen RockHard that's made with tung oil and phenolic resins. Durability wise, this formulation is better than an alkyd varnish but not quite as tough as a uralkyd varnish (polyurethane).

You don't want to apply a harder finish (varnish) over a softer finish (oil/varnish blend). That can lead to crazing and cracking. Bob Flexner's book "Understanding Wood Finishing" covers all this stuff in detail. Well worth the trip to your local library or bookstore.

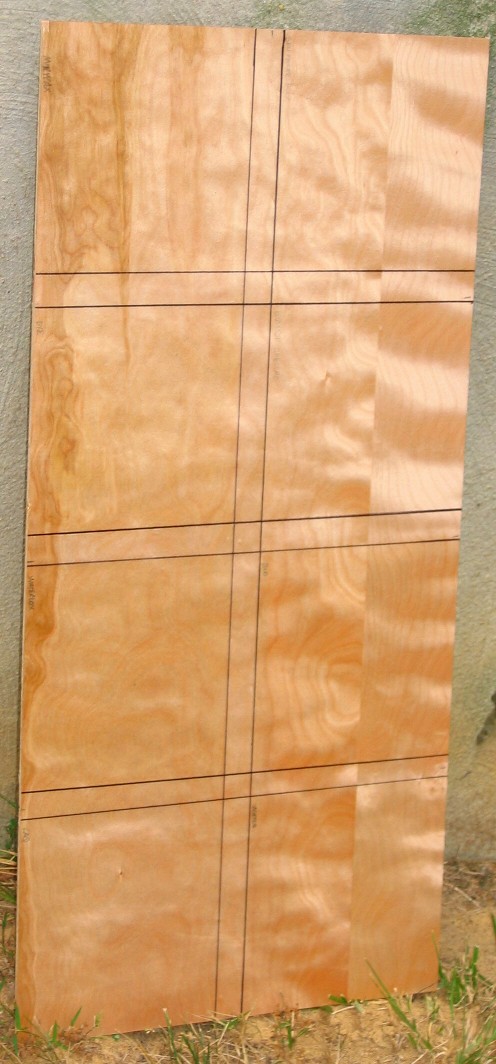

Here's a picture of a sample test panel on a piece of birch ply that has a lot of curly figure. Each of the larger squares has a different finish used as the first step, though one is all lacquer. The differences between the squares are subtle.

In French polishing, a drying oil like linseed is used to pop the shimmer/chatoyance and figure in the wood before the shellac is applied. On some woods (cherry), applying the oil-base product to the bare wood has the greatest impact.