Question

I am a recent graduate of Fine and Creative Woodworking at Rockingham Community College in Reidsville NC, and am producing a walnut slab table/desk for a client. I am preparing to attach the leg assembly to the slab, and am trying to determine what type of allowance on the joining points for the slab movement. The slab is 88" long, 2" thick and varies from 33" to 55" wide. In looking at a Dimensional Changes chart in an article from an old issue of Fine Woodworking by Tom Liebl, I see that a 12" slab of walnut dried to 7% will move .23". I assume that is a 4/4 bd.

Am I right in assuming that a 2" thick board will move about 1/2 as much due to the increased thickness? This logic tells me that I should leave around 3/8" on the front of the slab, and 1/2" on the rear. I am planning to use dowels to attach the legs to the slab, and screws for the front leg bracket.

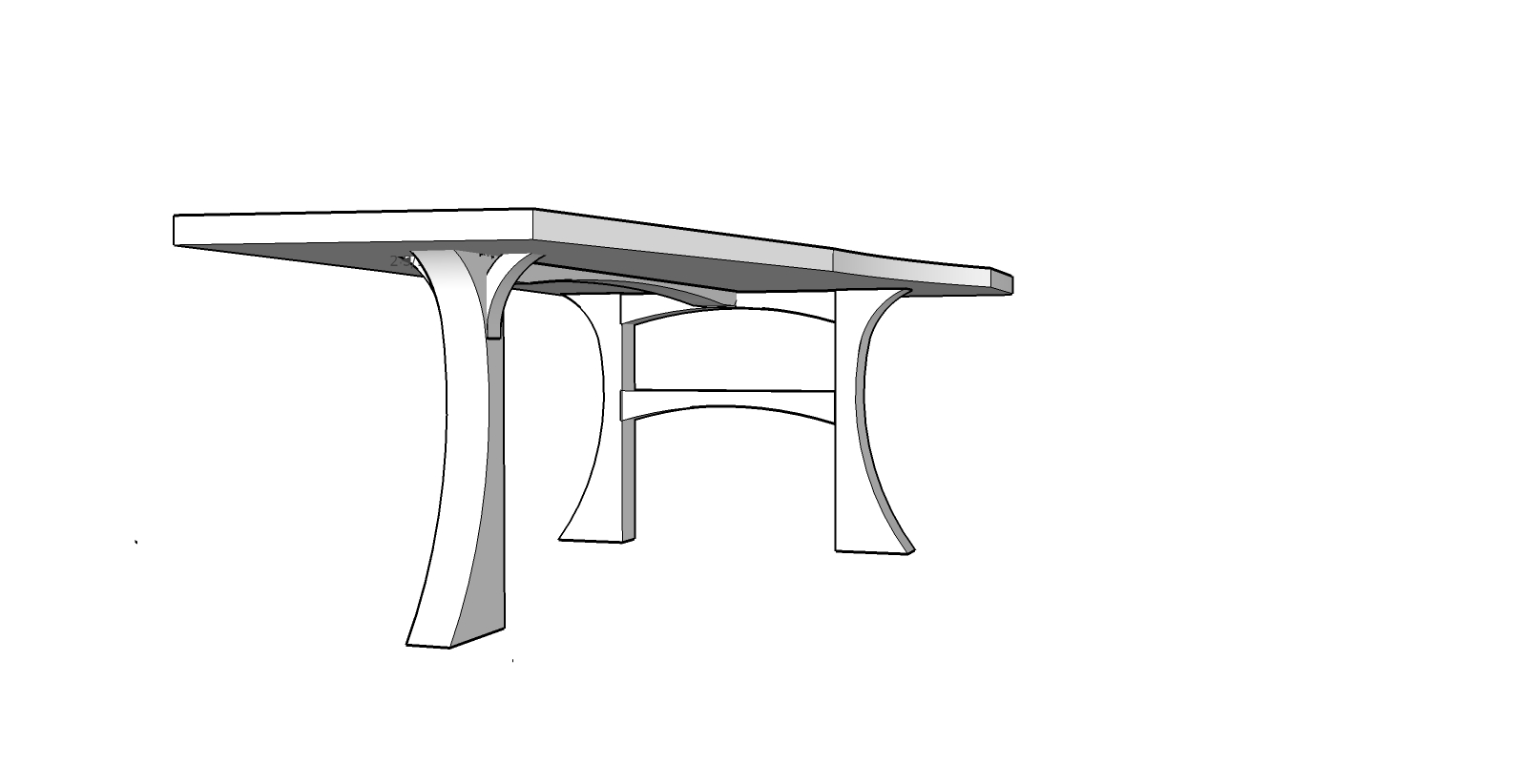

I've uploaded a jpeg from my SketchUp design to illustrate what the table looks like. Any help would be much appreciated!

Forum Responses

(Furniture Making Forum)

From contributor J:

I can't quite follow your logic. For a given change in MC, a width of a thick slab will change just as much as a thin one. The thin one will change faster, but not further. Seasonal movement across the 55" dimension should probably be around 3/8", assuming you use some sort of film finish. Your 1/2" allowance there would be plenty.

Note that the various members will get wider and narrower, but they won't get significantly longer or shorter. Your only movement challenge is where the slab meets the pair of legs shown towards the rear of the picture. That two leg assembly is going to stay essentially the same width, but the slab isn't. If you connect those back legs to the slab with dowels then the slab will push the rear leg assembly apart next summer. On the narrower end of the slab, where you've only got one leg, you can do whatever you want because the contact area between the slab and the leg is very small, and also because the slab and leg will move together anyhow.

I like the design, however if you terminate the curve of the legs to a feather edge as shown in the drawing you will live to regret it. If the short grain doesn't start breaking off in the shop it surely will after delivery to the customer.