Question

I have been commissioned to build a custom home library, and I am using sliding dovetails to join the shelves to the bookcase sides. The plan is to use HW ply for the sides, and 13/16 solid for the shelves. Wood choice is either mahagony or walnut, the client hasnít made a choice as of this moment. The question is regarding the size/angle/depth of the dovetail.

A few more details:

-The shelf depth will be about 10Ē.

-I am using face frames, so I can use through dovetails.

-I am leaving a 3/16Ē expansion gap at the back of the shelves, and gluing just the front edge of the joint to allow for movement.

Having not done this type of joint before, and knowing I have about 320 of these joints to do, I am relying on others advice (other than donít do it) to do it right. I am hoping for some advice on router bit selection, use of checking jigs to ensure consistency, etc. Also, I originally planned to use HHG for the joints, but am considering using CA to soak the front edges of the joint to lock into place. I use this method for binding flat-top guitars, and expect my instruments to last 100 years or more (so far no evidence to prove otherwise). The main reason for considering this method is because eight of the cases are curved, so it will be much easier to get everything fitted perfectly that way, without fighting work time.

Question

(Furniture Making Forum)

From contributor O:

I wonder if a sliding dovetail is the right joint to use. The plywood will be very prone to chipping out and will not have a lot of strength. The sliding dove tail joint would be a better choice if the sides of the case were also made of solid wood. For plywood a simple dado would work better.

Machining the sides I would do in two steps, first a straight bit, followed up with the dovetail bit, probably around 7-9 degrees. I might sub that to a CNC shop with that many to do. I'd probably set up a horizontal router table to do the ends of the shelves if it was too wide for the multi-router. Sounds like a nice job, have fun. I wouldn't rule out the dado till after you try the dovetails either.

1. Why dovetails? Did the client ask for fixed shelves? If so, dadoes would be sufficient and a lot less trouble.

2. In general, a case should be structurally sound without the shelves - the back holds the sides in position. No need to dovetail the shelves at all, they could be adjustable.

3. Curved cases? If the sides aren't parallel to each other, the sliding dovetail won't work.

4. You are setting up a finishing nightmare. If you aren't doing the finishing, then don't worry about it. If you are, have you accounted for the extra time to finish fixed shelves?

Please think this through again. You might spend some time looking for/at standard library construction - there's a good reason that most people do things the same way.

1. Why dovetails? Did the client ask for fixed shelves? If so, dadoes would be sufficient and a lot less trouble.

It was a selling point (valid or not) based on the clients past experience with bad construction. I know it sounds like a lot of work for little gain, but part of the attraction for me is ease of assembly. If the machining is within tolerance, and it will, there is no reason I canít slide everything together with 90min epoxy and the thing will be basically assembled. Yes that is perfect world thinking, but many factors can be controlled with careful planning.

2. In general, a case should be structurally sound without the shelves - the back holds the sides in position.

No need to dovetail the shelves at all, they could be adjustable. Definitely a consideration

3. Curved cases? If the sides aren't parallel to each other, the sliding dovetail won't work.

Actually, I can join one side to all the shelves, and then bring the other side into place.

4. You are setting up a finishing nightmare. If you aren't doing the finishing, then don't worry about it. If you are, have you accounted for the extra time to finish fixed shelves?

The shelves will be pre-finished, along with the sides, and the back.

Please think this through again. You might spend some time looking for/at standard library construction - there's a good reason the most people do things the same way.

Will do, I havenít cut a single piece of lumber yet, so until then. I have heard a lot of responses about the difficulty of doing this, but nothing to say impossible. I will weigh it out before proceeding.

1. Make the sides solid. Building in expansion stress is not the way to sell quality joinery.

2. Use a stopped sliding dovetail. I prefer well fitting joints assembled with yellow glue, where the stopped joint allows you to drive it home a bit at the end. (If you make it sloppy, use epoxy, and the stopped joint will help to keep your expensive, slippery, slow-setting glue from augmenting your finish to the neglect of the joint.) Depending on your design, stopping the dovetail might even allow you to attach face frames before finishing and assembly.

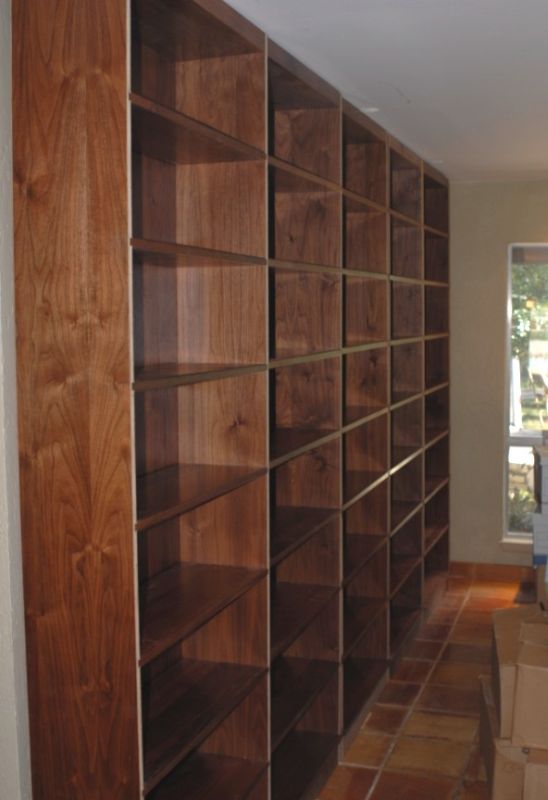

Here are some images.

Shelves in the drying room.